Titus Single Duct Terminal IOM User Manual

Installation manual, Single duct vav terminals

Installation Manual

SD-IOM-1.0

6-15-02

Single Duct VAV Terminals

Receiving Inspection

After unpacking the terminal, check it for

shipping damage. If any shipping

damage is found, report it immediately

to the delivering carrier. Store units in a

clean, dry location prior to installation.

Caution: Do not use the flow sensor,

connecting tubing, or damper shaft

linkage as a handle to lift or move

a s s e m b l y. Da m a g e t o t h e fl o w

sensor or controls may result.

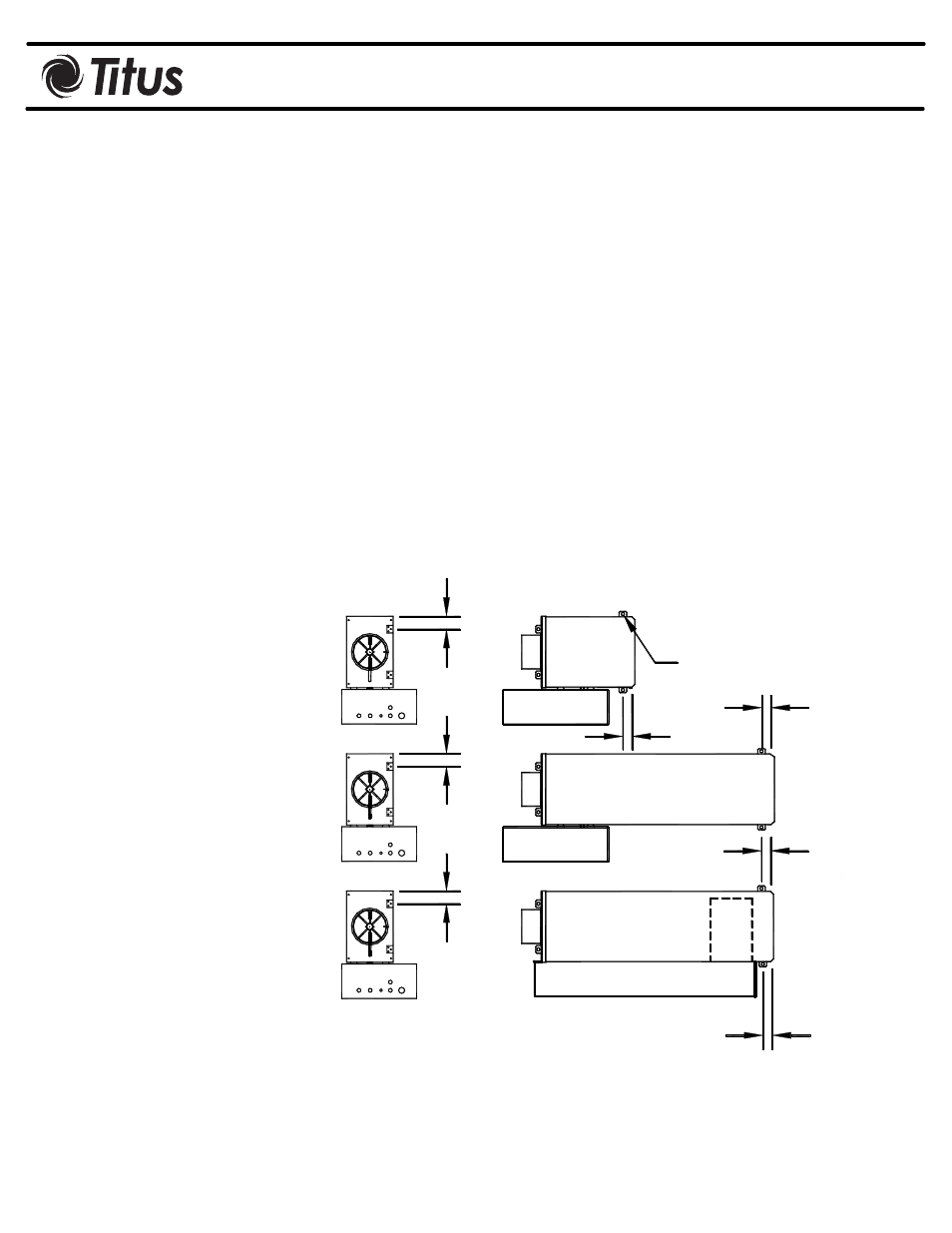

Supporting the Assembly

Many basic single duct terminals are

light enough to be supported by the duct

work itself. Where heavier accessory

modules, such as DDC controls, coils,

attenuators, or multiple outlets are

i n c l u d e d , t h e t e r m i n a l s h o u l d b e

supported directly. Straps screwed

directly into the side of the terminal,

threaded rod through the opti onal

hanger brackets (see Figure 1), or the

method prescribed for the rect angular

duct on the job specifications may be

used.

Important: If equipped with pneumatic

controls, the terminal must be mounted

right side up. It must be level within

+ or - 10 degrees of horizontal, both

parallel to the air flow and at the right

angle of air flow. The control side of the

terminal is la b e l e d wi t h a n a r r o w

indicating UP. The first letter of the

model number (P) indicates pneumatic

controls. Most electronic units (A- analog

controls and D-digital controls) can be

installed in any orientation. Check with

the local TITUS representative for

verification.

Duct Connections

Slip each inlet duct over the inlet collar

of the terminal. Fasten and seal the

connection by the method prescri bed by

the job specification.

The diameter of the inlet duct "D" in

inches must be equal to the listed size

of the terminal; e.g. a duct that actually

measures 8 inches must be fitted to a

size 8 terminal. The inlet collar of the

terminal is made 1/8 inch smaller than

listed size in order to fit inside the duct

(see Figure 1).

Note: Do not insert duct work inside

the inlet collar of the assembly.

Inlet

duct should be installed in accordance

with SMACNA guidelines.

Th e o u t l e t e n d o f t h e t e r m i n a l i s

designed for use with slip and drive duct

connections. A rectangular duct the size

o f t h e t e r m i n a l o u t l e t s h o u l d b e

attached.

If single-point electronic velocity sensor

is used, 3 to 5 inlet duct diameters of

straight duct should be provided at the

terminal inlet; for specific guidelines,

consult the manufacturer’s installation

material. Sensor(s) may be attached to

the inside of control enclosure for

protection during shipping. Sensor must

be inserted in inlet duct of terminal

b e f o r e o p e r a t i o n . R e m o v e a n y

protective plastic devices from tip of

sensor before installation.

Figure 1. Single Duct Recommended Hanger Bracket Locations

2" TYP

2" TYP

2" TYP

70738001

Hanger Bracket

1 1/2" TYP

1 1/2" TYP

1 1/2" TYP

1 1/2" TYP

W / ATTENUATOR

W / ELECTRIC HEAT

Optional