Steriflow Mark 978INLINE Series User Manual

Page 4

M

ark

978 S

anitary

G

lobe

-S

tyle

C

ontrol

V

alVeS

- J

orlon

D

iaphraGM

S

eal

J

orlon

D

iaphragm

s

eal

(1-1/2" – 2")

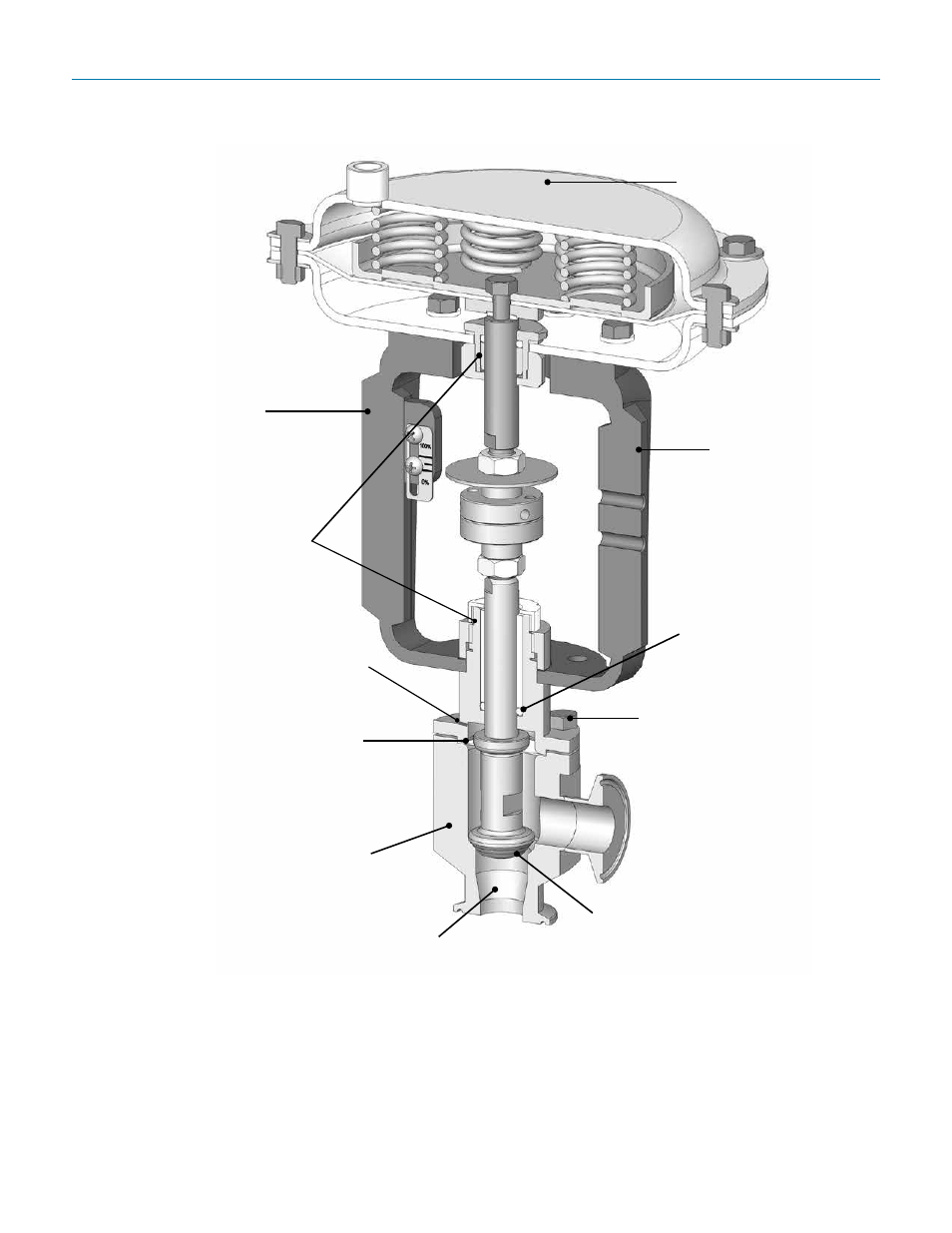

Corrosion resistant coating

with SST fasteners

Namur yoke permits

easy mounting of a

variety of positioners

Extended PEEK guide bushings

ensures smooth, stable move-

ment throughout entire stroke

length

FDA/USP Class VI Jorlon diaphragm

resistant to aggressive chemicals,

suitable for continuous steam service;

Lifetime Warranty

Contoured plug design for true equal

percentage or linear flow characteristic

throughout entire stroke length

Solid 316L barstock construction offers

excellent chemical resistance, ensures

consistent material integrity and surface

finish

Bolted bonnet provides

enhanced strength and

safety over clamped bonnet

Corrosion resistant SST

yoke assembly suitable for

washdown

-4-

FDA/USP Class VI

secondary stem seal

Optimal flow inlet geometry for true flow characteristics.

Self draining geometry in either vertical or horizontal

orientation allows installation flexibility

s

peciFication

Stainless steel sanitary control valve shall be made from ASTM A479 316L barstock material, which includes

body and all wetted metal parts. Control valve with the stem sealed by FDA approved and USP Class VI certi-

fied Jorlon diaphragm with lifetime warranty. The valve stem shall be supported by a one piece, SS NAMUR

Yoke to provide structural rigidity in any installation orientation. Guiding of valve stem/plug shall be outside of

the wetted process areas of valve above diaphragm. Control valve shall have secondary stem seal, and extend-

ed guide bushing to provide additional support for multiple installation orientations. Valve shall be self draining

in any orientation.

Telltale weephole between

primary diaphragm and secondary

stem seal per ASME BPE 2009