Steriflow JSB Series User Manual

Page 3

-3-

JSB S

erieS

B

io

-P

harma

G

aS

B

ack

P

reSSure

r

eGulatinG

V

alVe

F

eatures

& B

eneFits

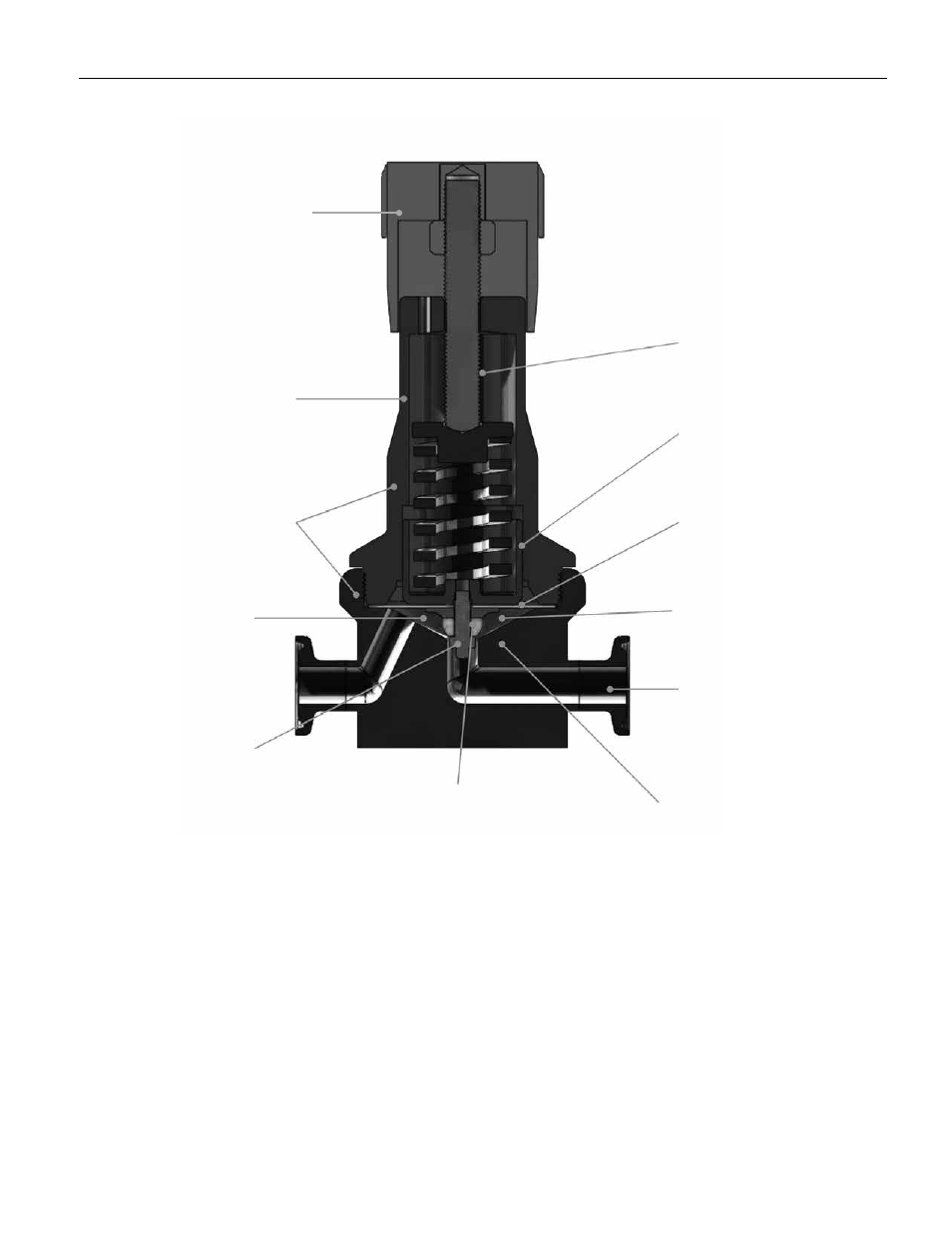

SST spring chamber

suitable for washdown

ASME BPE SF5, 20 Ra μin

(0,5 Ra μm) electropolish -

standard

Metal trim

components

100% 316L

FDA/USP Class VI seat and seal

material for ANSI Class VI shutoff

Optimized minimal

internal volume

Sanitary clamp

connections

Jorlon Diaphragm

FDA/USP Class VI

approved – unsurpassed life

Fine thread pitch for

precision setpoint

adjustments

First compact gas regulator

fully drainable in both vertical

and horizontal installation

No cracks, crevices or

threads below diaphragm

Guiding done above

the wetted process

To select a valve with the proper Cv:

1. Convert pressure and flow units to those shown on graph.

2. Select the graph below with a flow range (x axis) that encompasses the minimum and maximum flows

of your installation, and with an appropriate outlet regulated pressure range (y axis). Note: Your max

flow cannot exceed either of the graphs, nor can your desired set point be below 4 psi, or above 125

psi. Note also that the maximum inlet pressure allowed is 150 psig.

3. Plot your desired set point on the graph you chose above, at the flow rate you expect that set point.

4. Pick an outlet pressure spring range flow curve that contains your set point. Eg. 50 - 125 psi, 35-60 psi, etc.

5. Draw a curve with the same slope as #4 above parallel to the spring range flow curve you have

chosen through your plotted set point. That curve approximates the flow of your valve under operating

conditions.

6. Note that you may also use the SFCV sizing program for Globe style valves to calculate approximate

flow or Cv.

Autoclavable Anodized

Aluminum Knob available

as cataloged option