Steriflow JSR Series User Manual

Page 4

JSR S

eRieS

H

igH

P

uRity

B

io

-P

HaRma

g

aS

P

ReSSuRe

R

educing

V

alVe

t

rim

F

low

(c

v

) s

election

G

raphs

J p

erFormance

0.5 c

v

0

10

20

30

40

50

0

10

20

30

40

50

60

70

80

90

100

P1 = 150 psig

P1 = 150 psig

P1 = 100 psig

P1 = 100 psig

Air Flow (SCFM)

Outlet Pressure - P2 (psig)

J p

erFormance

0.8 c

v

0

10

20

30

40

50

Air Flow (SCFM)

60

70

80

0

10

20

30

40

50

60

70

80

90

100

P1 = 150 psig

P1 = 150 psig

P1 = 100 psig

P1 = 100 psig

Outlet Pressure - P2 (psig)

-4-

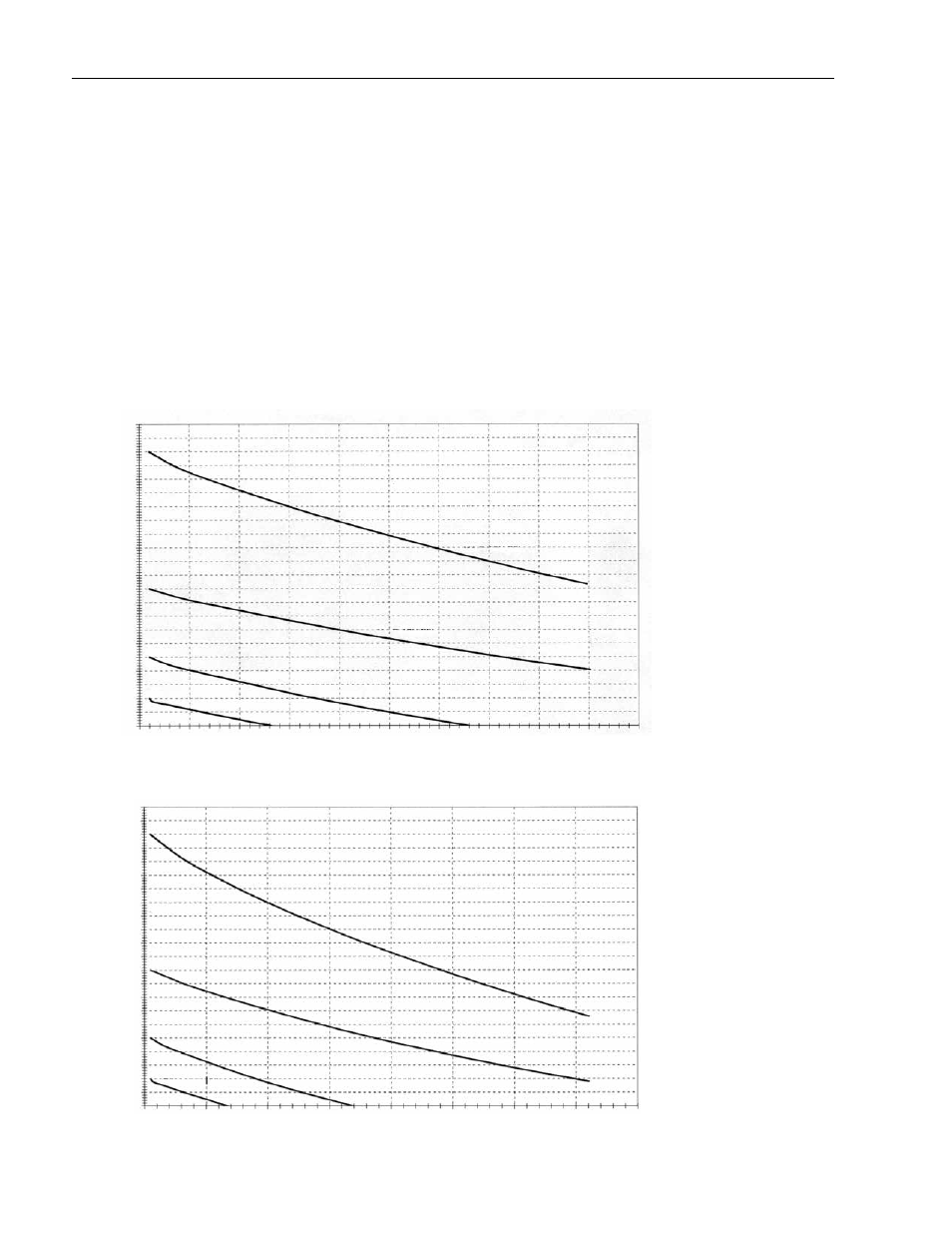

To select a valve with the proper Cv:

1. Please note maximum inlet pressure, and seat temperature limitations on page 2. Select a seat material appropriate for that temperature

and the gas flowing through the valve.

2. Convert pressure and flow units to those shown in the graphs below.

3. The sloped lines are the flow curves associated with either a 150 psi or 100 psi inlet pressure (P1). Make sure the application inlet pres-

sure is between 100 and 150 psi.

If not, contact the factory.

4. Select the graph that encompasses the minimum and maximum flows of your installation (horizontal axis), and with an appropriate outlet

regulated pressure (vertical axis).

5. Plot your desired set point on the graph you chose, at the flow rate you expect at that set point.

6. Pick the P1 inlet pressure curve in your graph that is closest to your valve installation inlet pressure.

7. Draw a curve with the same slope parallel to that curve through your plotted set point. That curve approximates the flow of your valve

under operating conditions.

Note: if your operating conditions and media are outside the bounds of either graph, consult factory.