Steriflow JSR Series User Manual

Page 2

-2-

JSR S

eRieS

H

igH

P

uRity

B

io

-P

HaRma

g

aS

P

ReSSuRe

R

educing

V

alVe

s

peciFications

Sizes:

1/2" (DN15) & 3/4" (DN20)

Ends:

Clamp, Weld-stub or NPT ends

Soft Seat Materials for ANSI Class VI Shut-Off:

• PTFE to +252°F (122°C) continuous or 275°F (135°C)

intermittent [not to exceed 15 min. in a one hour

period]

FDA, USP Class VI

• PEEK to +350°F (176,7°C) FDA, USP Class VI

• EPDM to +300°F (150°C) FDA, USP Class VI

Body Material:

316L SST

Diaphragm Material:

PTFE-based Jorlon FDA, USP

Class VI

Maximum Inlet Pressure:

150 psig (10,5 bar)

Spring Ranges:

5–70 psi (0,3–4,8 bar); 50–125 psi

(3,4–8,6 bar)

Flow Characteristics:

• High Flow: Trim Cv 0.8; Cv for relief valve

sizing is 1.9

• Low Flow: Trim Cv 0.5; Cv for relief valve

sizing is 0.6

Surface Finish:

Mechanically polished to 20 Ra µ

in (0.5 µm), and electropolished as standard. Other

finishes available upon request

Options:

• Panel Mounting

• Captured Vent

• Self Relieving

o

ptions

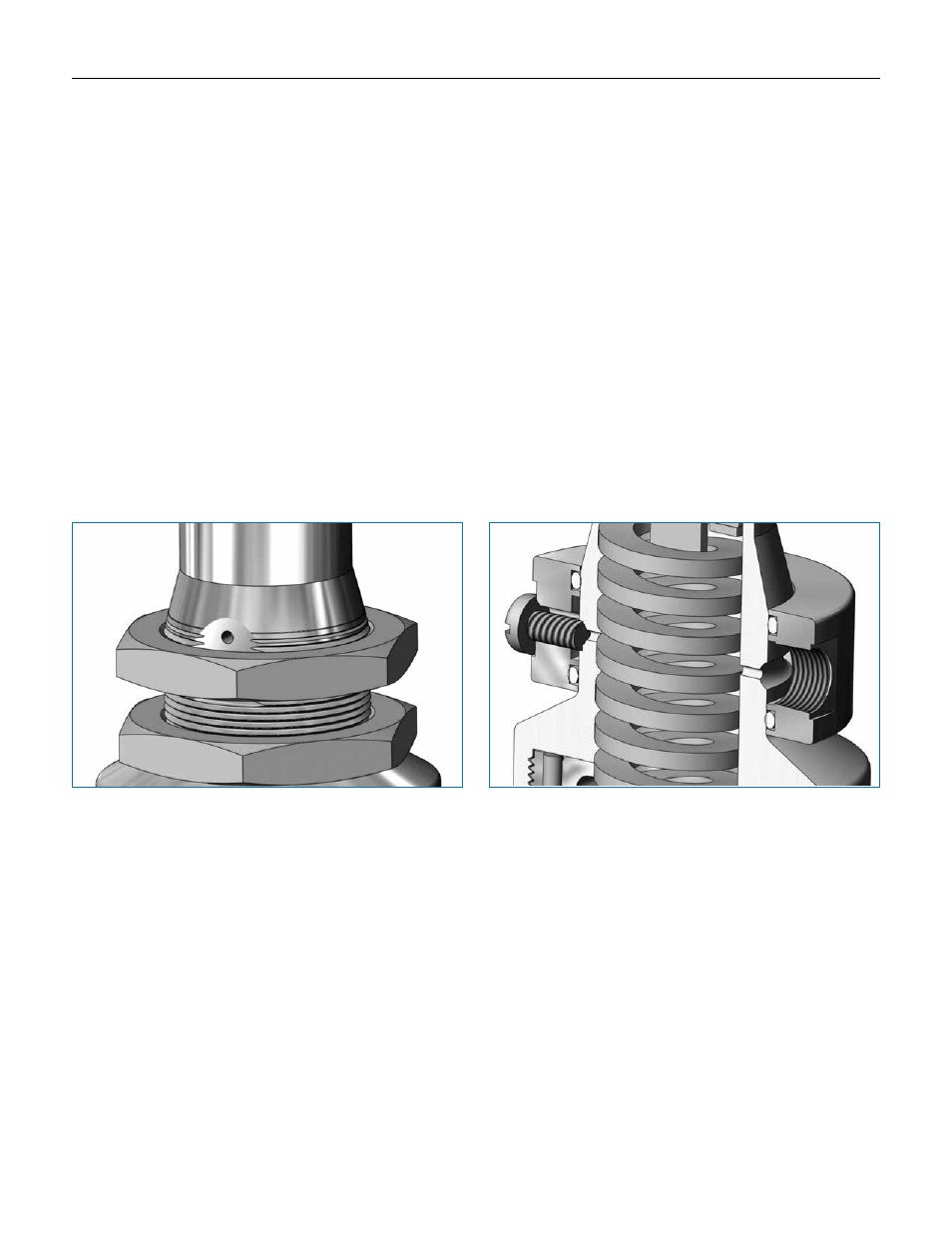

Panel Mount Option

Captured Vent Option (1/8" NPT)

o

ption

D

eFinition

Captured Vent

The captured vent design is for maximum safety for the user when handling toxic or hazardous media. It

features a 1/8" FNPT port located on the spring housing. The user can easily tube this vent to a safe loca-

tion. This option can be incorporated into a self-relieving regulator that provides an additional port to permit

the safe expulsion of hazardous media.

Panel Mount

The panel mount feature requires a panel cut out of 1-1/2", complete with a threaded spring housing, and a

panel mount ring to secure the regulator.

*Self Relieving

The self relieving option is used for internal venting of downstream pressure. From a practical standpoint, it

allows for immediate reduction in pressure setpoints and automatically alleviates regulator lock up.

(Recommended with outlet gauges)