7 cleaning and service, Cleaning and service, Warning – Retsch AS 200 jet User Manual

Page 44

Cleaning and service

44

Pos : 14.1 /0020 Übersc hrift en/1. Übersc hrift en/1 Rei nigung und Wart ung @ 0\ mod_1231167007723_9. doc x @ 5450 @ 1 @ 1

7 Cleaning and service

Pos : 14.2 /0025 War nhi nweis e/ W0003 WARNUNG R ei nigung Str omst oß neu @ 1\ mod_1236239978437_9.doc x @ 7686 @ @ 1

WARNING

Risk of a fatal electric shock

-

An electric shock can cause injuries in the form of burns and cardiac

arrhythmia, respiratory arrest or cardiac arrest.

• Do not clean the blender under running water. Use only a cloth dampened

with water.

• Disconnect the power supply plug before cleaning the blender.

Pos : 14.3 /0001 Bedienungsanlei tungen/ 00106 Kapi tels ammlung AS200J et/ 0010 AS200J et Rei nigung und Wart ung/AS200Jet M odul R einigung und Wartung @ 1 \ mod_1235638688043_9. doc x @ 7479 @ 33 @ 1

7.1.1

Cleaning

We recommend Retsch ultrasonic baths for thorough, gentle and time-saving

cleaning of your test sieves.

Ask for our free special publication

“Looking after and cleaning test sieves”.

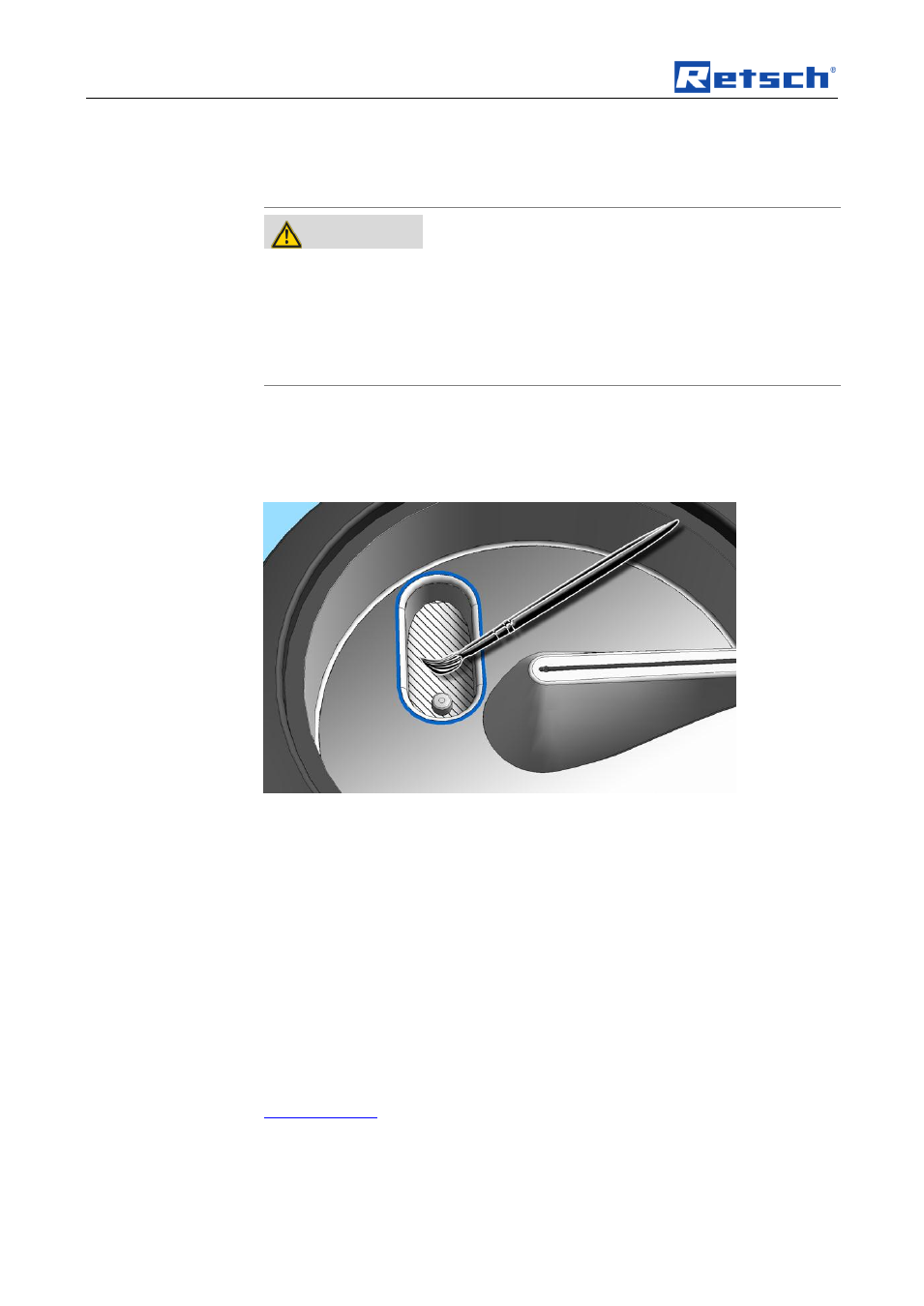

Fig. 22: Cleaning the air outlet channel

Clean the air outlet channel regularly using a brush to remove any deposits.

7.1.2

Vacuum cleaner

– changing the vacuum cleaner bag

Change the vacuum cleaner bag or empty the dust container on your vacuum

cleaner regularly as required.

Check the degree of soiling of the vacuum cleaner filter regularly and change the

filter where applicable.

The vacuum or differential pressure generated by the vacuum cleaner may

otherwise be too low for sieving.

Pos : 14.4 /0001 Bedienungsanlei tungen/ 00106 Kapi tels ammlung AS200J et/ 0010 AS200J et Rei nigung und Wart ung/AS200Jet M odul War tu ng @ 1\mod_1249992352900_9. doc x @ 13778 @ 2 @ 1

7.1.3

Maintenance

This device is essentially maintenance-free if cleaned regularly.

It is possible to calibrate the differential pressure sensor within the context of the

DIN EN ISO 9001:2000 ff. Please contact your dealer or Retsch GmbH.

Pos : 14.5 /0020 Übersc hrift en/1.1 Ü bersc hriften/ 1. 1 Ü berschrif ten BDA/11 Kali brieren des Druc ks ens ors ( überpr üf en des Diff ere nzdr uc kes ) @ 2\ mod_1277971514050_9.doc x @ 20528 @ 2 @ 1

7.2 Calibrating the pressure sensor (checking of the differential pressure)

Pos : 14.6 /0005 RET SCH/ 0005 R ETSCH Bedienungsanlei tungen Kapit elsamml ung en/AS200Jet/ 0010 AS200J et R ei nigung und Wart ung/ AS200J et Modul Kalibri erung @ 2\ mod_1277967985047_9. doc x @ 20520 @ @ 1

•

Unscrew the sealing screws (MS).