Unloading & assembly – MacDon 5010 Mower Conditioner User Manual

Page 74

72

UNLOADING & ASSEMBLY

ATTACH HYDRAULICS AND ELECTRICAL

(continued)

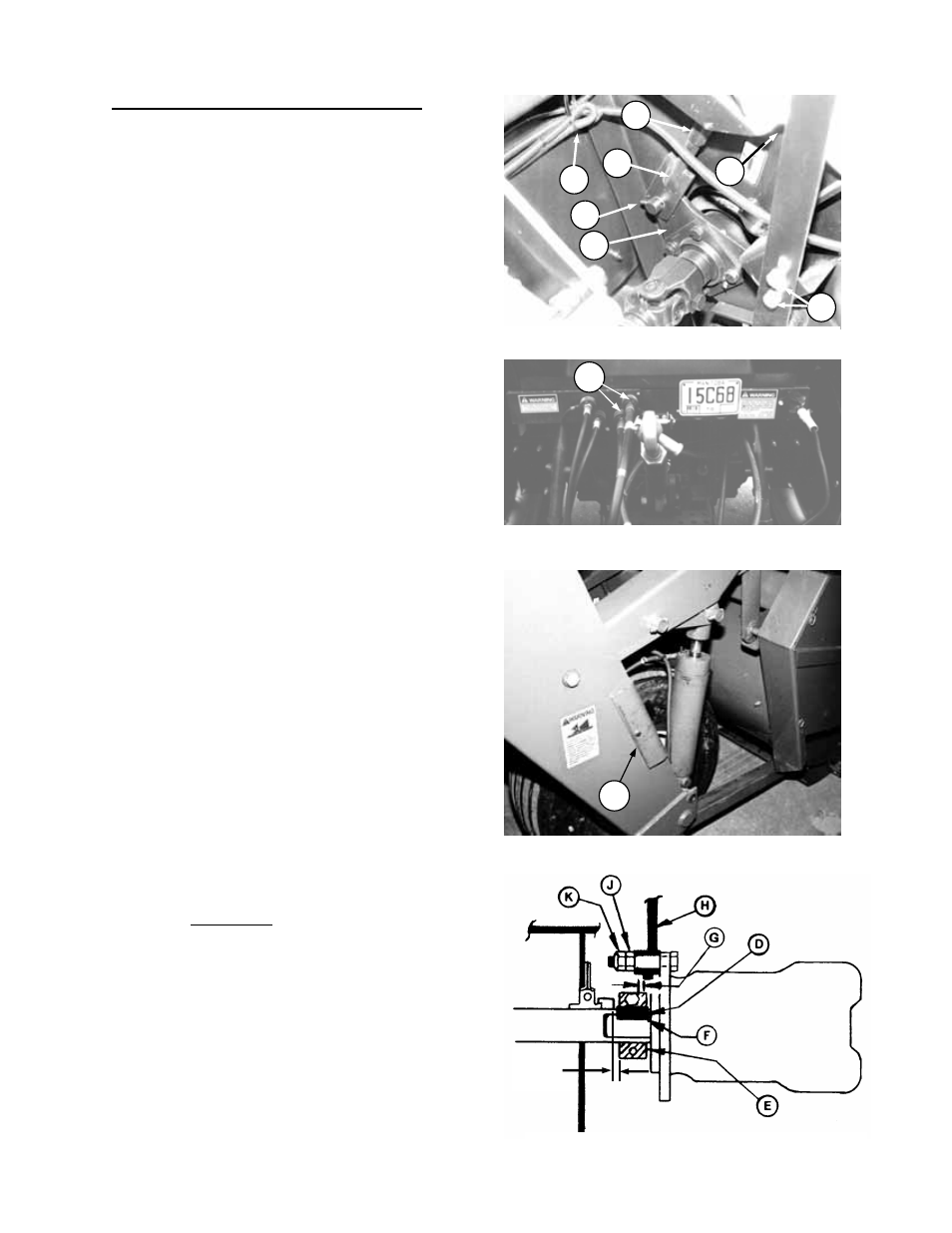

4. Attach motor to header primary drive:

NOTE: For easier installation of motor onto

shaft, hoses may be completely removed from

motor at swivel fittings. A minimal amount of oil

will drip out, however extreme care must be

taken to prevent dirt from entering at hose ends

and motor ports. If removing hoses, go to step

(c).

a) Complete the following steps to increase

clearance for motor installation:

− Before lowering header, remove spring pin (A)

at L/H roll gap adjustment rod.

− Lower header to ground: Connect the two lift

cylinder hoses (T) to tractor so that when the

tractor control is moved back, the lift cylinder

will extend, raising the header. When the

tractor control is moved forward, the lift

cylinder will retract, lowering the header. Move

the lift cylinder stops to storage position (U)

and lower header. Before header will lower,

cycle the control up and down a few times to

fill lines. It may be necessary to loosen float

springs to allow header to lower.

− Rotate conditioner rolls so that keyway slot in

drive shaft is at the top. Remove roll gap

adjustment rod (B) as follows:

Measure exposed thread at top of rod and

record for reassembly.

Unscrew adjustment tube (L) from rod (B).

Remove rod (B) from left support arm (C).

− Remove two bolts (N) securing support bar to

frame and pivot the bar rearward.

− Remove torque arm (H) from header frame.

b) Loosen fittings on motor about 1/2 turn to allow

hoses to swivel.

c) Install motor on drive shaft using key (D)

between two clamp halves (E):

- IMPORTANT: Push motor onto shaft so that

key (D) bottoms out in motor shaft keyway at

(F).

- If motor shaft will not slide into drive shaft bore,

use a large screwdriver or bar to spread the

drive shaft keyway.

- When positioning motor for installation, motor

hoses should be in cut-out (P) in frame.

- Position clamps for 1/4" (6 mm) clearance (G)

between clamp and bearing lock collar (when

installed in step d).

- Torque clamp bolts to 75 ft.lbs. (100 N

⋅m).

6 mm

(1/4”)

INSTALL MOTOR & ATTACH TORQUE ARM

REMOVE ROLL GAP ADJUSTMENT ROD

R

B

A

C

P

L

N

ATTACH HEADER LIFT HOSES

T

CYLINDER STOP STORAGE

U