Maintenance/service – MacDon 5010 Mower Conditioner User Manual

Page 51

49

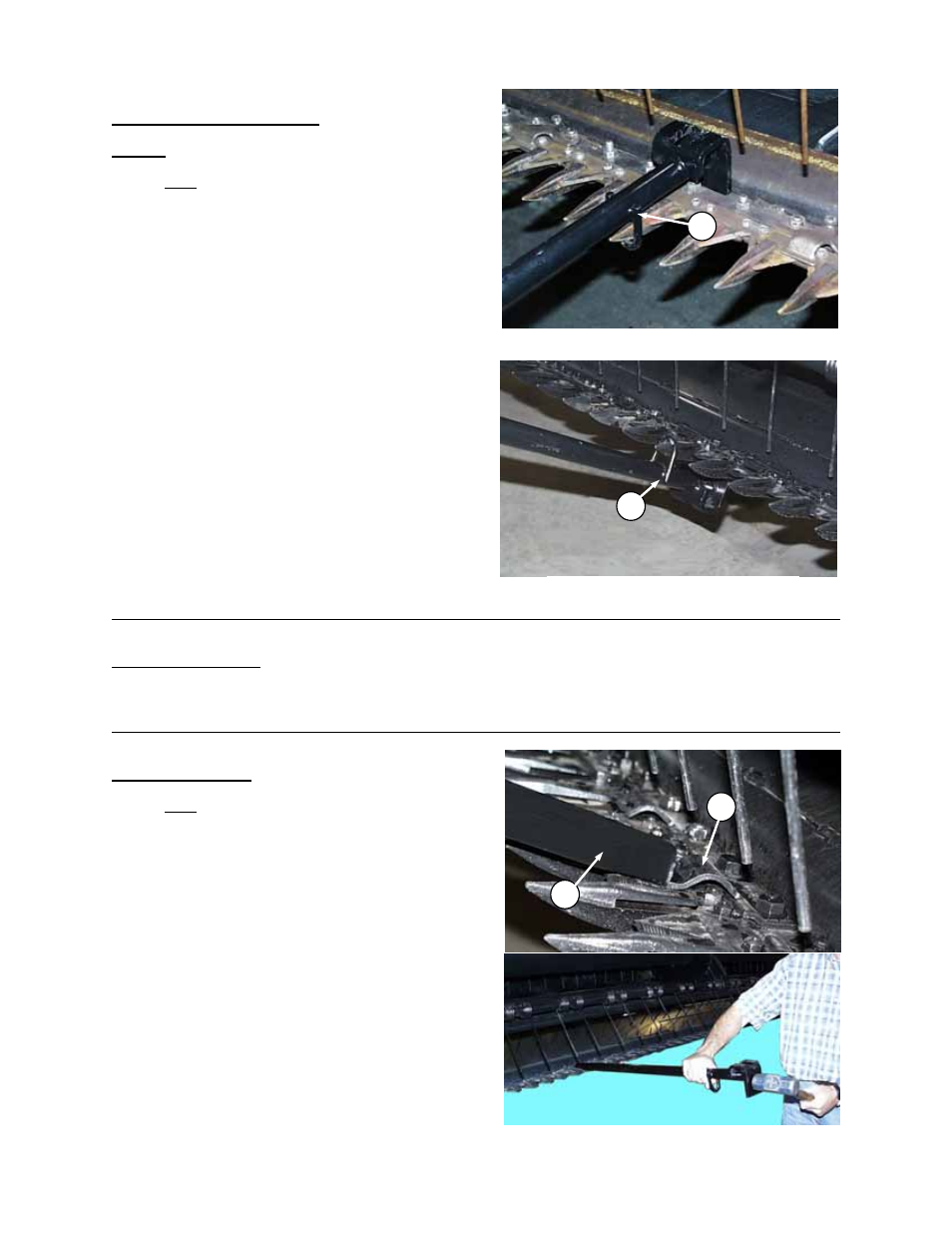

BENDING GUARD TIPS UP

A

BENDING GUARD TIPS DOWN

B

MAINTENANCE/SERVICE

SICKLE AND SICKLE DRIVE (continued)

Guards

Check daily that guards are aligned to obtain

proper shear cut between sickle section and

guard. Sickle sections should contact shear

surface of each guard.

Align guards with guard straightening tool provided

as shown:

To bend guard tips up, position tool as shown at

(A) and pull up.

To bend tips down, position tool as at (B) and push

down.

NOTE: Tool is stored in toolbox at right end of

main frame.

TIP: If trouble is encountered cutting tangled, but

easy to cut material (canola, peas, grain) replace

guards with stub guards and install a sickle hold-

down on every guard. If material is tough to cut,

install stub guards with top guard and adjuster

plate. A stub guard conversion kit for the 5010

Windrower is available from your dealer.

Excessive Breakage

Excessive breakage of sickle sections and guards can be controlled by several factors. See "Cutting Height",

"Cutterbar Angle" and "Header Flotation" in Operation section for recommendations.

Sickle Hold-Downs

Check daily that sickle hold-downs are set to

prevent sickle sections from lifting off guards but

still permit sickle to slide without binding. Set hold-

downs after guards are aligned.

To set hold-downs:

1. Use the unplug wrench (A) with the flattened

end against the front edge of hold down. Strike

wrench with a hammer. This allows adjustment

of hold-down arch (B) without "pinching" sickle.

Clearance from hold-down to sickle section

should be .020 inch (0.5 mm).

2. After adjusting all hold-downs, run header at a

low engine speed and listen for noise due to

insufficient clearance. Re-adjust as necessary

by placing a .020 inch (0.5 mm) shim between

hold-down and section, then striking the hold-

down arch (B) with a hammer.

SETTING SICKLE HOLD-DOWNS

A

B