Unloading & assembly – MacDon 5010 Mower Conditioner User Manual

Page 72

70

UNLOADING & ASSEMBLY

INSTALL TONGUE

IMPORTANT: If there is more than one machine to

be assembled, and they are different sizes (12 ft.,

14 ft., 16 ft.), be sure the proper tongue is matched

to each unit. Tongues are identified on a plastic

tag tied to the hose support near the front end.

Should this tag be missing, tongues can be

identified by length as follows:

HEADER SIZE TONGUE

LENGTH *

12 ft.

17' 7" (5360 mm)

14 ft.

19' (5780 mm)

16 ft.

21' 7

1/2

" (6590 mm)

* Tongue length is measured from center of pivot

hole at back end to center of hitch pin hole at

front end.

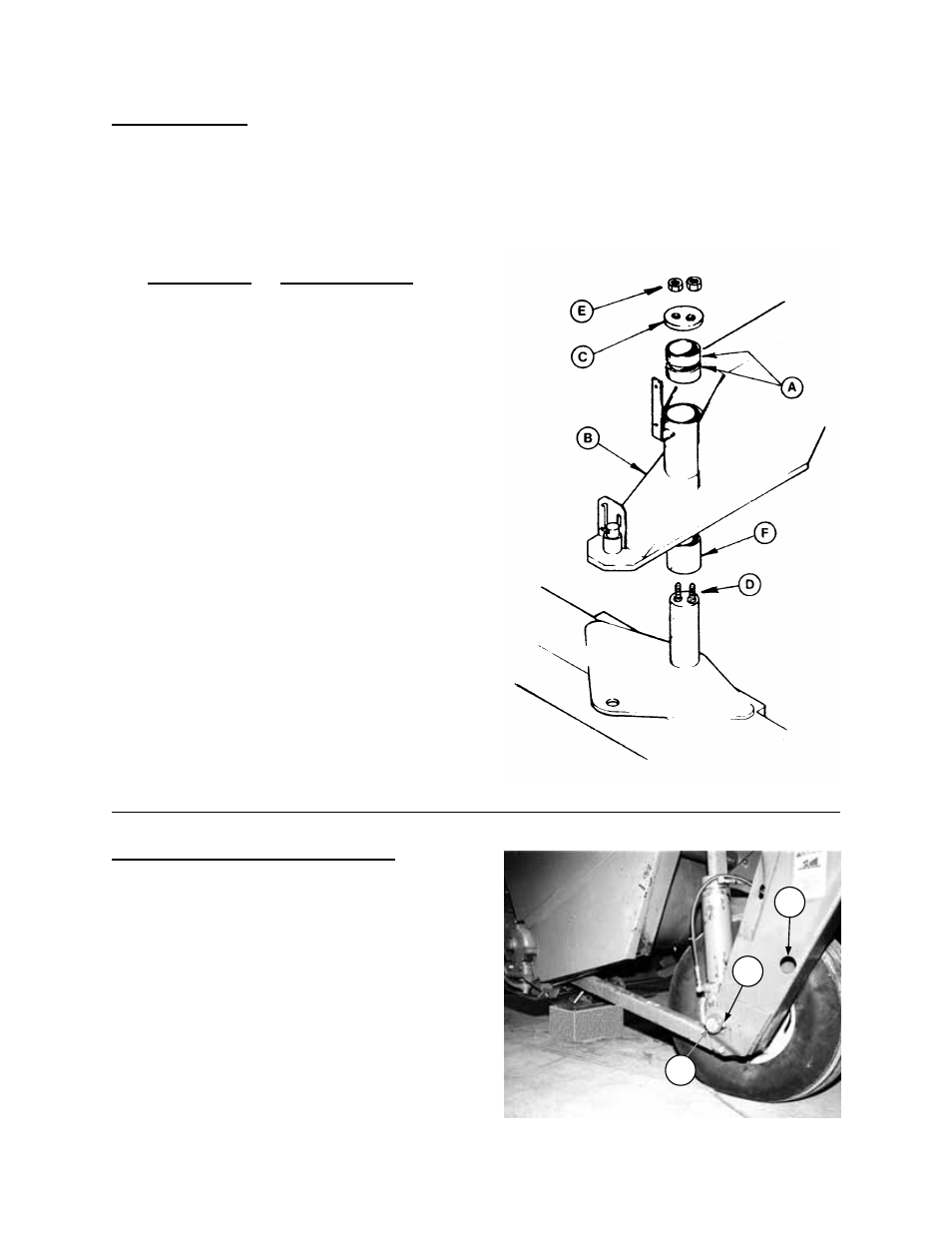

1. Ensure plastic bushings are installed in pivot

hole at back end of tongue. Remove shipping

wire.

NOTE: The two shorter bushings (A) install

from top of tongue, the longer one (F) from the

bottom.

2. Install jack in working position at front of

tongue.

3. Attach chain from lifting vehicle or hoist to

tongue as described on page 69. Lower tongue

(B) onto pivot pin. NOTE: Use the jack to adjust

the pitch of the tongue for proper alignment

when installing onto pivot pin.

4. Install retainer (C) on top of tongue, over pivot

pin bolts (D).

5. Install two 5/8 lock nuts (E) and tighten to 160

ft.lbs. (215 N

⋅m).

6. Remove lifting brackets from tongue when

complete.

INSTALL WHEELS IN FIELD POSITION

1. Raise rear of machine and move wheels from

shipping position (A) to field position (B).

NOTE: For 12 ft. unit (both wheels) and 14 ft.

unit (left wheel only), remove spindle retaining

bolt and nut (C) and slide spindle outboard until

clearance to vertical float spring is adequate for

wheel removal from spindle. When reinstalling

wheel bolts, torque to 120 ft.lbs. (160 N

⋅m)

2. Torque the 1/2 inch lock nut (C) to 80 ft.lbs.

(110 N

⋅m).

3. Lower machine onto the tires.

4. Check tire inflation pressure. Adjust to 30 psi

(207 kPa).

INSTALL WHEELS IN FIELD POSITION

A

B

C

INSTALL TONGUE