Operation – MacDon 5010 Mower Conditioner User Manual

Page 35

33

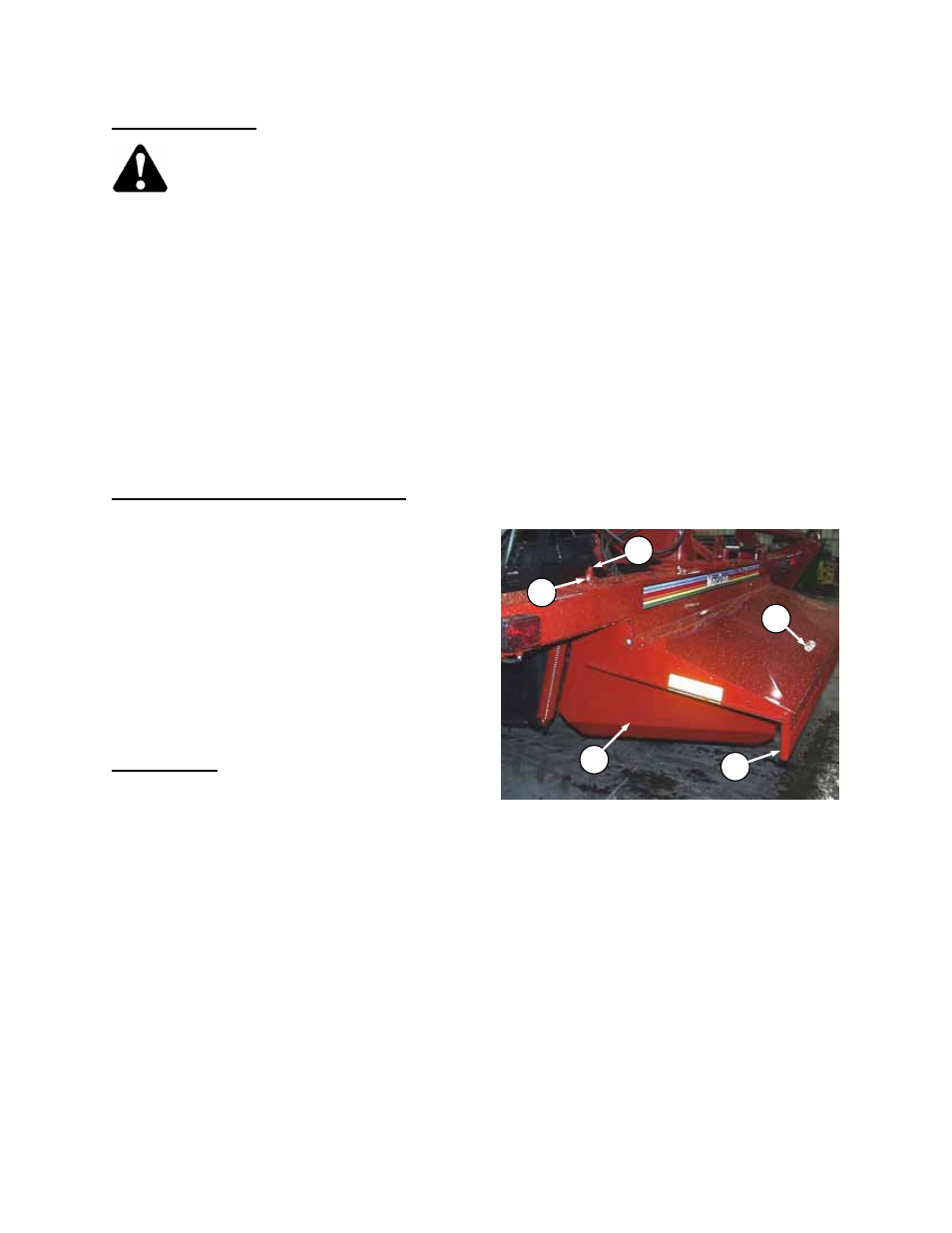

FORMING SHIELD ADJUSTMENTS

D

C

B

A

E

OPERATION

FORMING SHIELDS

WARNING: Keep hands and feet away from discharge opening. Keep everyone several

hundred feet away from your operation. Never direct the discharge toward anyone. Stones or

other foreign objects can be ejected with force.

The position of the forming shields controls the width and placement of the windrow. The decision on forming

shield position (infinite settings between 30 and 92 inches [760 - 2346 mm]) should be based on the following

factors:

- weather conditions (rain, sun, humidity, wind)

- type and yield of crop

- drying time available

- method of processing (bales, silage, "green-feed")

A wide windrow will generally dry faster and more evenly, resulting in less protein loss. Fast drying is

especially important in areas where the weather allows only a few days to cut and bale. See "Haying Tips" in

this section for more information.

Where weather conditions permit or when drying is not critical, for example, when cutting for silage or "green-

feed", a narrower windrow may be preferred for ease of pick-up.

To adjust windrow width and placement:

IMPORTANT:

Position L/H and R/H forming shields (B) so they

are the same distance from centerline of tongue

pivot. Measure at rear of deflector. (Decal (E) on

top forming shield provides base line for

measurement). Adjust to desired width.

NOTE: If forming shields (B) are too loose, or too

difficult to move, adjust torque of lower nut (A) to

100 ft.lbs. (135 N

⋅m). Then, holding nut (A) with a

wrench, tighten top nut (D) securely against nut

(A).

Rear Deflector

The rear deflector (C) slows the crop exiting the

conditioner rolls, directs the flow downward, and

"fluffs" the material.

The rear deflector can be adjusted down for more

crop control in light material, and up for clearance

in heavier crops.

To adjust rear deflector, pull up or push down one

side of deflector (C), then repeat at the other side.

There is no hardware to be loosened.

NOTE: For even windrow formation, be sure the

deflector is not twisted.