Operation – MacDon 5010 Mower Conditioner User Manual

Page 33

31

OPERATION

HEADER FLOTATION

Header flotation springs are normally set so 70 lbs. force (311 N) is required to lift either end of the header just

off the ground.

In rough or stony conditions, it may be desirable to change setting to 35-50 lbs. (156-222 N) to protect cutting

components.

NOTE: When float setting is light, it may be necessary to use a slower ground speed to avoid excessive

bouncing and leaving a ragged cut.

To increase header flotation, which decreases the force required to lift header:

a. Raise header fully.

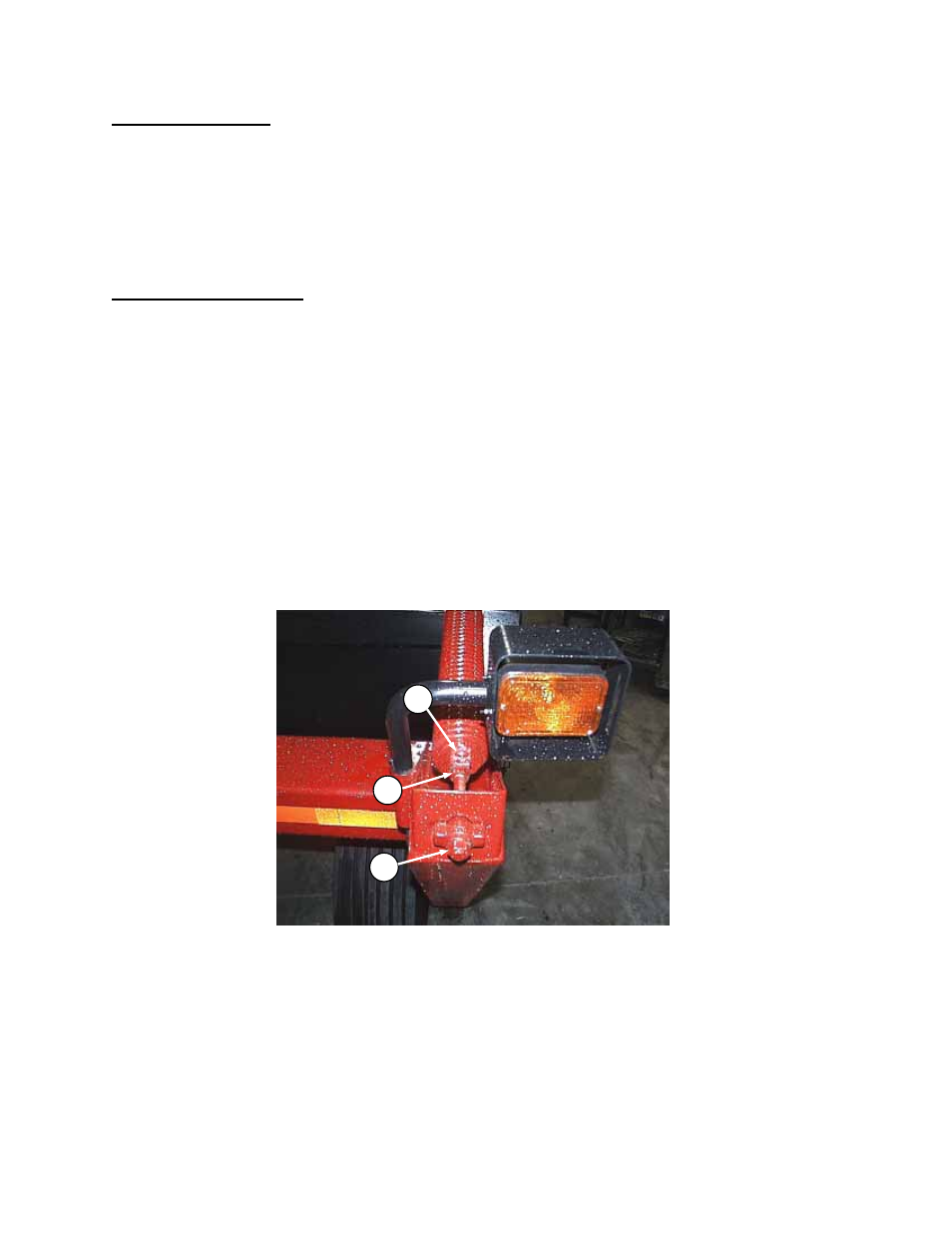

b. Back jam nut (A) away from spring.

c. Turn adjuster bolt (B) further into spring to increase flotation.

d. Tighten jam nut (A) against spring insert (C) to secure the setting.

e. Lower header and check header flotation at each end.

IMPORTANT: Float setting (or lifting force) must be equal on both springs. Weight difference between left and

right ends requires different spring lengths to achieve equal float at both ends. Note that other operating

variable adjustments may affect float setting. Check the float and readjust if necessary after adjusting reel

position, cutting height, or cutterbar angle. Also, if using a tractor with drawbar height different than 16 inches

(406 mm) flotation will be affected. Adjust as required.

HEADER FLOTATION ADJUSTMENT

C

A

B