Operation – MacDon 5010 Mower Conditioner User Manual

Page 34

32

OPERATION

ROLL GAP

WARNING: To avoid bodily injury or

death from unexpected start-up or fall

of raised machine; stop engine,

remove key and engage lift cylinder

stop before going under machine to

examine rolls or for any other reason.

Steel rolls "condition" the crop by crimping the

stem in several places. This allows moisture

release for quicker drying. The degree to which the

crop is conditioned as it passes through the rolls is

controlled by roll gap (A), measured from bar to roll

tube. The gap is factory set at 3/8 inch (10 mm) for

normal operation.

Correct conditioning of alfalfa, clover and other

legumes is usually indicated when 90% of the

stems show cracking, but no more than 5% of the

leaves are damaged. Use only enough roll gap to

achieve this result.

A slightly larger gap (up to 7/8 inch [22 mm]) may

be desirable in thick stemmed cane-type crops;

however, too large a gap will cause feeding

problems.

Grass type crops may require less gap for proper

feeding.

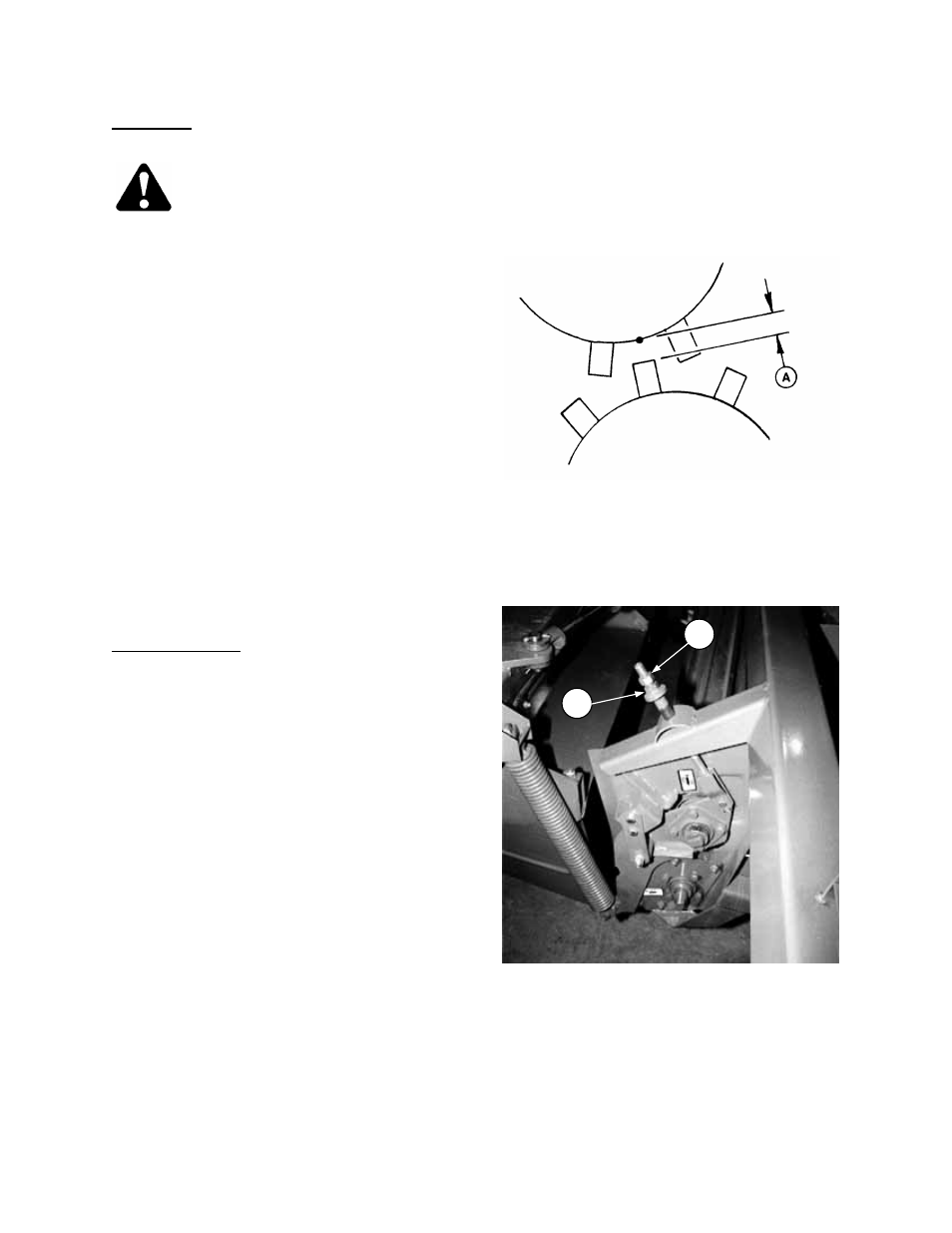

To adjust roll gap:

a. Raise header fully.

b. Loosen jam nut (B), both sides.

c. To increase roll gap, turn nut (C) clockwise.

d. To decrease roll gap, turn nut (C) counter-

clockwise.

e. Tighten jam nut (B), both sides.

f. Lower header and inspect roll gap along the

length of the rolls.

IMPORTANT: Gap settings must be equal at both

ends of roll.

NOTE: Roll tension (the force holding the rolls

together) is factory set and non-adjustable.

ROLL GAP ADJUSTMENT

B

C

ROLL GAP