Maintenance/service – MacDon 871 Combine Adapter User Manual

Page 18

18

MAINTENANCE/SERVICE

RECOMMENDED LUBRICANTS

GREASE

SAE Multi-Purpose High Temperature Grease with Extreme Pressure (EP) Performance and containing at

least 1.5% molybdenum disulphide.

Also acceptable is an SAE Multi-Purpose Lithium Base Grease.

HYDRAULIC OIL

Use single grade trans-hydraulic oil. To prevent machine damage, do not use engine oil.

The following oil company and equipment

manufacturer brand names are recommended:

Petro Canada Duratran

Case IH Hy-Tran Plus®

John Deere Quatrol® J20C

Agco Power Fluid 821XL

The following oil company and equipment

manufacturer brand names are acceptable:

New Holland Hydraul

Esso/Exxon Hydraul 56

Shell Donax TD

GEARBOX OIL

SAE 85W-140 gear lubricant (API Service Classification GL-5)

CAPACITIES

Adapter Gearbox - 450 mL (15 U.S. oz.)

Adapter Hydraulic System (Draper Drive)

Full system: 25 litres (6.6 U.S. gals.)

Tanks only: 17 litres (4.5 U.S. gals.)

STORING AND HANDLING LUBRICANTS

Your machine can operate at top efficiency only if clean lubricants are used. Contaminant in lubricants is the

most likely cause of bearing and hydraulic system failure. Use clean containers to handle all lubricants. Store

lubricants in an area protected from dust, moisture and other contaminants. Keep hydraulic couplers and

connectors clean.

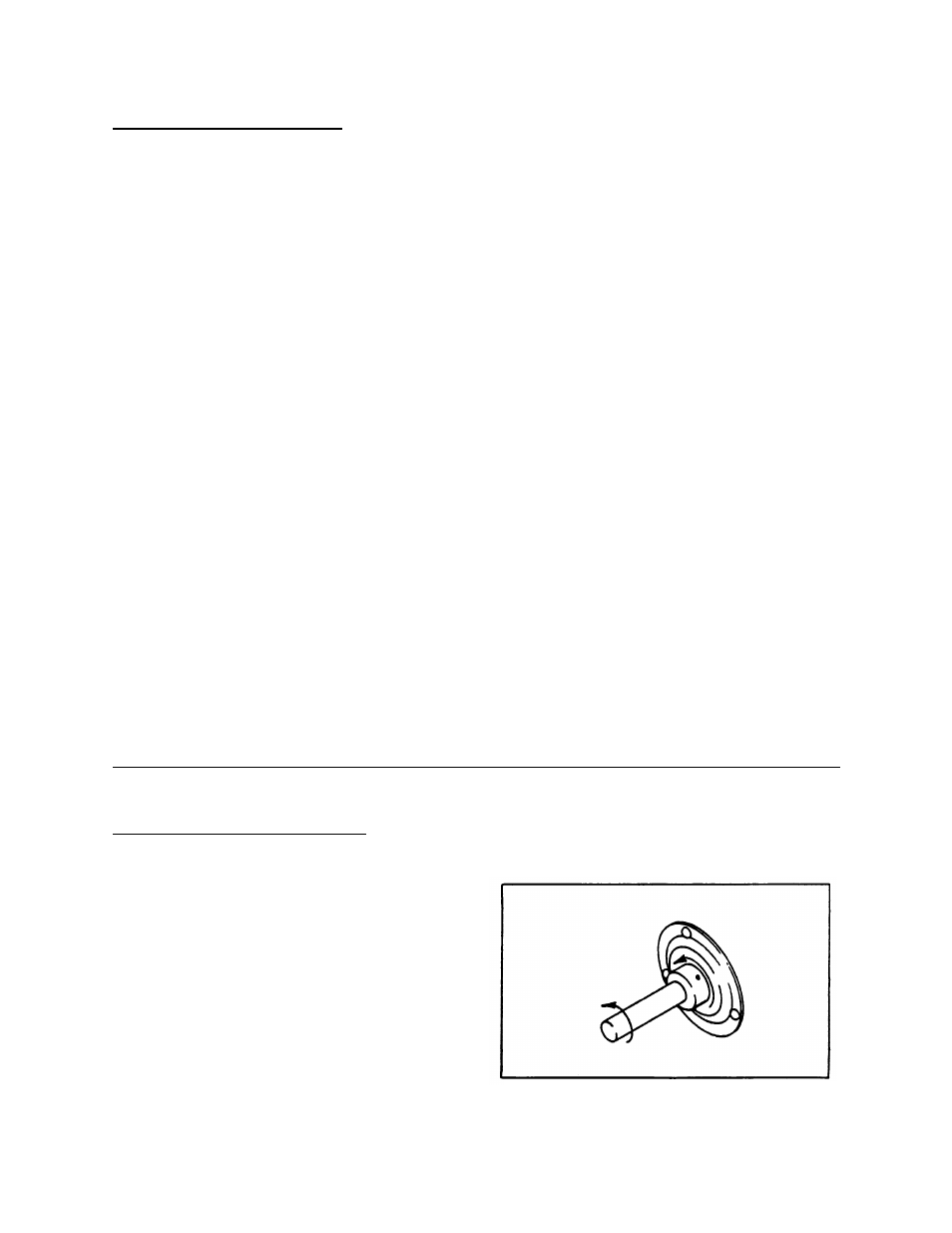

SEALED BEARING INSTALLATION

1. Clean shaft and coat with rust preventative.

2. Install flangette, bearing, flangette and lock

collar. The locking cam is only on one side of

the bearing.

3. Install and tighten the flangette bolts.

4. When the shaft is located correctly, lock the

lock collar with a punch. The collar should be

locked in the same direction the shaft rotates.

Tighten the set screw in the collar.

5. Loosen the flangette bolts on the mating

bearing one turn and re-tighten. this will allow

the bearing to line up.

TIGHTEN COLLAR IN DIRECTION

SHAFT ROTATES