Mg-30 pump — maintenance (pump), Caution, Lubrication lines maintenance – Multiquip MG30M2D User Manual

Page 52

PAGE 52 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

SPEED REDUCER UNIT

The speed reducer unit is of a constant-mesh type and totally

enclosed, with all gears running in oil. CHECK THE OIL LEVEL

EVERY WEEK.

The speed reducer should be completely drained every 6 months.

Refill with a good grade of S.A.E. 30 Oil. CAUTION: KEEP OIL

AT THE PROPER LEVEL. Too much oil will cause overheating

and too little oil will cause gear failure. When the adding of oil to

the speed reducer is required. Reference the "

Speed

Reducer

Oil Check

" section on page 38.

MG-30 PUMP — MAINTENANCE (PUMP)

LUBRICATION

LINES

MAINTENANCE

1

2

3

4

5

6

7

8

9

GREASE DAILY,

EVERY ZERK

1

2

3

4

5

6

7

8

9

Cam Rocker Arm Bushings

Gear Box Block (Back)

Cam Rocker Arm Roller

Connecting Rod. (Up)

Cam Rocker Arm

Gear Box Block (Front)

Connectings Rod. (Down)

Crank Rocker Arm (Bushings)

Crank Rocker Arm

Use: No. 2 Multipurpose

Automotive Grease

(Bearing Housing)

(Bearing Housing)

513164

1

2

4

3

5

6

7

8

9

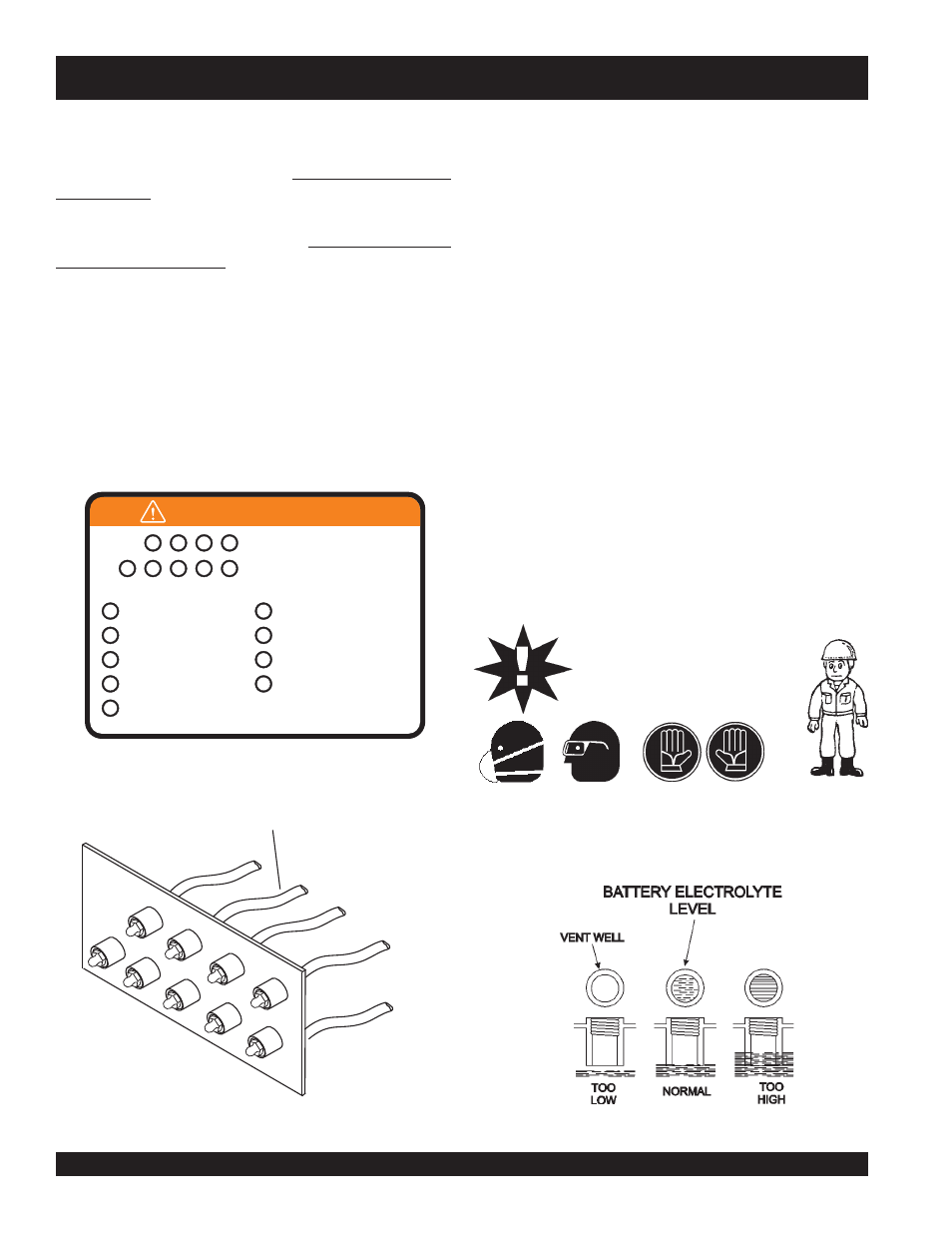

LUBRICATION PANEL

Located on the side of the pump is a lubrication panel (Figure 51).

Grease

all ports daily

with two to three shots of #2 multi-purpose

automotive grease. Over-greasing any bearing will not damage

the machine.

Wear

safety glasses

or

face

mask

, protective clothes, and

rubber gloves when working

with battery.

CAUTION :

BATTERY MAINTENANCE

Mishandling of the battery shortens the service life of the battery

and adds to maintenance cost. When handling the battery do

the following:

Be careful not to let the battery electrolyte come in

contact with your body or clothing.

Always wear eye protection and rubber gloves, since

the battery contains sulfuric acid which burns skin and

eats through clothing.

Always check the battery terminals periodically to

ensure that they are in good condition.

Use wire brush or sand paper to clean the battery

terminals.

Always check battery for cracks or any other

damage. If white pattern appears inside the battery

or paste has accumulated at the bottom, replace

the battery.

If the pump will not be in operation for a long period

of time, store in cool dry place and check the

battery charge level every month to maintain the

performance of the battery.

Check the battery regularly and make sure that each

electrolyte level is to the bottom of the vent well

(Figure 52). If necessary add only distilled water in a

well-ventilated area.

Figure 51. Lubrication Panel

Figure 52. Battery Electrolyte Levels