Caution, Mg-30 pump — maintenance (mixer) – Multiquip MG30M2D User Manual

Page 48

PAGE 48 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

SHAFT SEALS

CAUTION:

IMPORTANT -DRUM HEAD SEAL CARE

Grease seals every

40 hours

of operation

using any grade #1 lithium base grease. Apply

grease until visible inside of mixing tub (over

grease). This will purge seal system of

contamination.

GEAR/CLUTCH REDUCTION ASSEMBLY LUBRICATION

The gear/clutch reduction assembly has two separate

compartments. Each of which must be filled with its proper

lubricant and checked at regular intervals.

The

clutch compartment

should be filled with a good grade of

number 30 SAE engine oil which can be poured through the

filler hole located just above the clutch inspection door on the

opposite side of the transmission. Fill the clutch compartment

with 30 SAE engine oil until it overflows the oil level plug located

on the shifter side of the clutch compartment . Check this oil level

every two or three months and add oil as required. Drain and

refill once a year.

The

reduction gear, upper compartment

should be filled with

number 90 SAE oil, as used in automobile transmissions. The

filler plug is at the top of the reduction gear case and the oil level

plug is on the same side of the case as the clutch lever. Fill the

reduction gear compartment with 90 SAE transmission oil until it

overflows the oil level plug. Check this oil level every two or

three months and add oil as required. Drain and refill once a

year.

PADDLE SHAFT BEARINGS

The paddle shaft in the MQ ESSICK EM120SM mixer rotates in

sealed ball bearings, which require no additional lubrication as

they are packed and sealed at the factory.

There is, on each end of the mixing drum, a zerk grease fitting

(pivot point). Grease these fittings once a week as they lubricate

the dumping mechanism of the mixing drum.

Failure

to lubricate

the zerk grease fittings once a week will cause the dumping

mechanism to stiffen, making the mixer hard to dump.

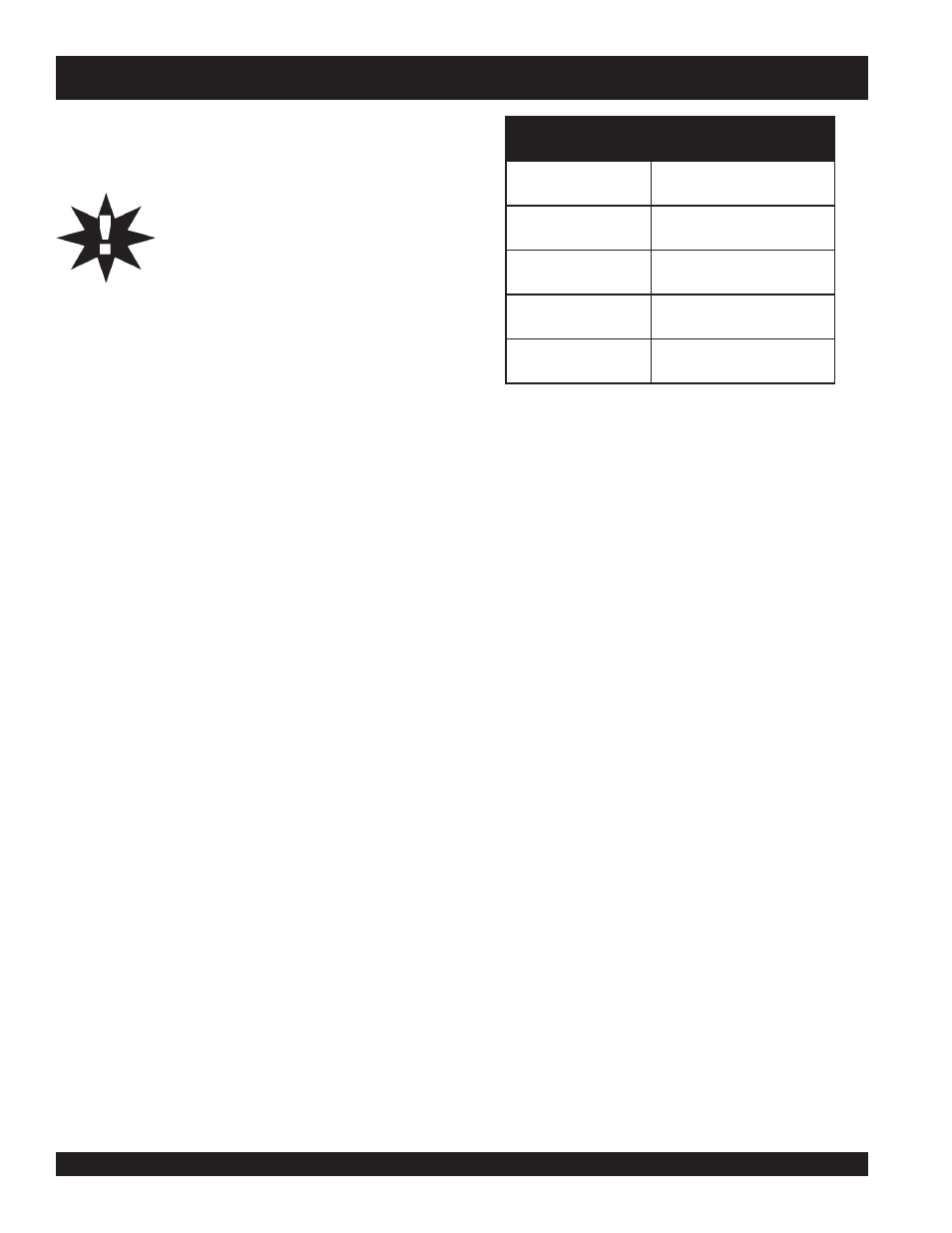

HARDWARE

Check all hardware on the mixer before starting. Periodically

inspect all hardware. Loose hardware can contribute to early

component failure and poor performance. Use Table 11 (Torque

Chart) as a general guideline and keep all hardware tight.

ENGINE OIL

1. If mixer's engine oil is low, fill engine crankcase with

lubricating oil through filler hole, but DO NOT overfill.

2. The oil listed in Table 7 is recommended to ensure better

engine performance. Use class CD or higher grade motor

oil.

AIR CLEANER (DRY TYPE)

1. Change the air cleaner every 500 hours. See Figure 12

for location of air cleaner.

FUEL FILTER/FUEL TANK

1. Change the fuel filter every 500 hours.

2. Siphon water out of fuel tank once a year.

CLEANING

ALWAYS make sure engine is OFF before cleaning the inside

of the drum. NEVER put hands, fingers or arms inside mixing

drum when engine is ON.

NEVER pour or spray water over engine.

For consistent performance, long life and high quality mixing,

thoroughly clean the mixer inside and out at the end of each

day’s operation. To prevent lumps of dried mortar from forming

and contamination of future batches, DO NOT allow a buildup of

materials to form on the blades or anywhere inside the drum.

MG-30 PUMP — MAINTENANCE (MIXER)

t

r

a

h

C

e

u

q

r

o

T

.

1

1

e

l

b

a

T

r

e

t

e

m

a

i

D

e

r

a

w

d

r

a

H

e

u

q

r

o

T

)

m

m

4

9

.

7

(

8

1

-

"

6

1

-

5

m

/f

g

k

7

1

1

(

.

s

b

l/

tf

4

2

2

)

)

m

m

3

5

.

9

(

4

2

-

"

8

/

3

m

/f

g

k

0

8

1

(

.

s

b

l/

tf

7

3

2

)

)

m

m

0

7

.

2

1

(

3

1

-

"

2

/

1

m

/f

g

k

0

9

1

(

.

s

b

l/

tf

9

3

2

)

)

m

m

0

7

.

2

1

(

3

1

-

"

2

/

1

8

e

d

a

r

G

m

/f

g

k

9

3

4

(

.

s

b

l/

tf

0

9

2

)