Mg-30 pump — application – Multiquip MG30M2D User Manual

Page 25

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 25

NOTE

NEVER place the MG-30 into

operation without a safety relief

pressure valve with a manual

release control installed on the

pump discharge.

MG-30 PUMP — APPLICATION

NOTE

ALWAYS

point the brass cap on the

safety valve

downward

. This will

prevent the ball from striking

someone and possibly causing

injury.

Suggestion:

DO NOT use a 1000 psi cap if your pumping requirement is less

than 750 psi.

Always

use a cap that is rated less than the total

system pressure.

The rubber ball will stay in place until an excessive amount of

pressure occurs that will cause the ball to

blow

out through the

opening (Figure 8) in the brass cap and release the pressure in

the hose or line.

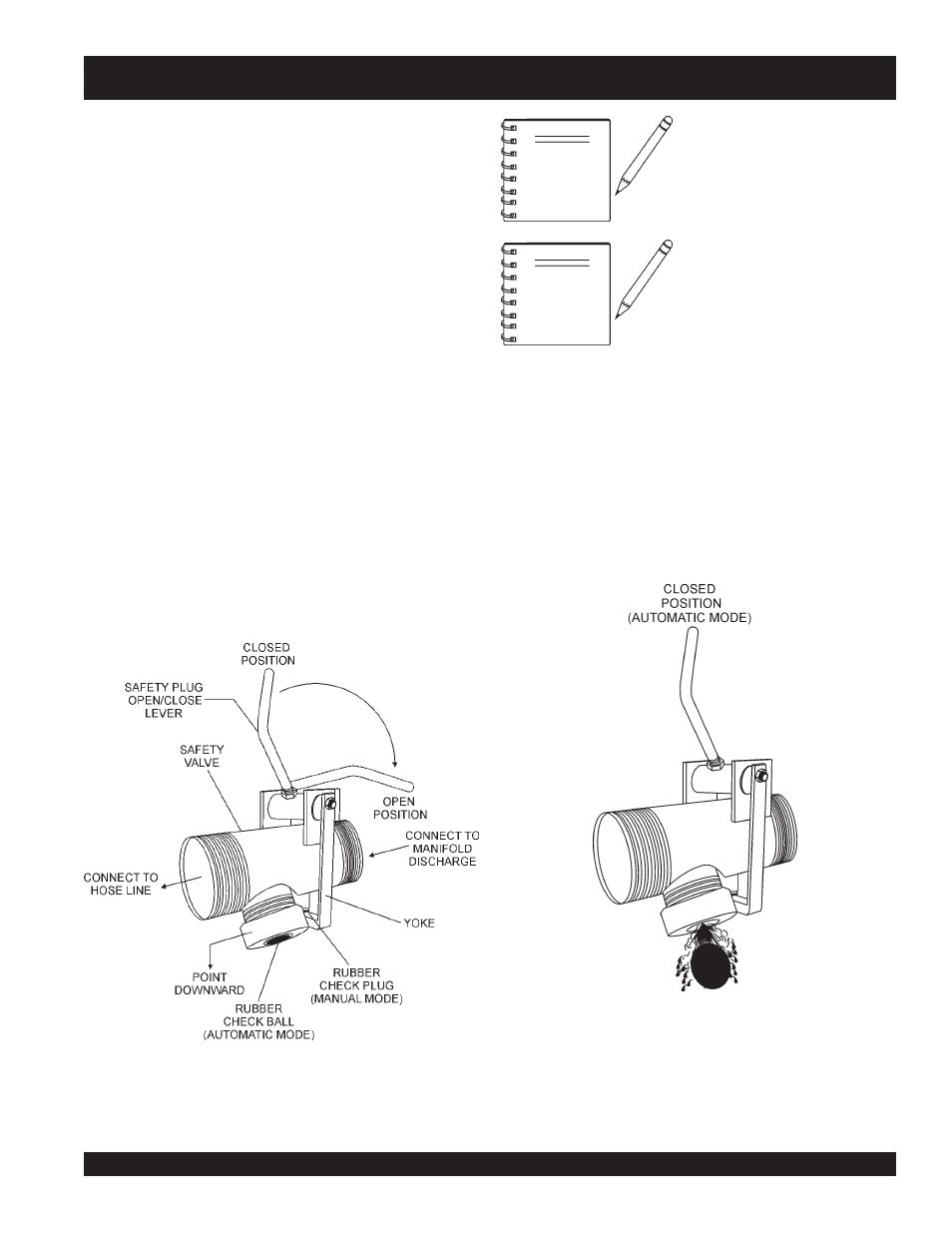

Pressure Relief Valve (Automatic)

Purpose

To provide the capability that will

automatically

release the

pressure in a material hose or line whenever the flow of material

is restricted for any reason, causing unsafe pressure to build up

in the hose or line.

Safety Valve Placement (Automatic)

Place the automatic safety valve at the outlet side of the plaster

pump, ahead of the hose connection. This automatic safety valve

is to be used in conjunction with the manual release mechanism

(

safety relief pressure plug

).

Theory of Operation

Located on the

bottom

of the

safety relief pressure valve

(Figure 7), is a pipe nipple with an opening which is sealed off

with a rubber ball that is held against the opening with a

brass

cap

.

It is the responsibility of the pump operator to ensure that the

delivery hose and line system with all clamps and accessories

have a higher pressure rating than the safety cap being used.

Figure 7. Safety Relief Pressure Valve

(Automatic Mode)

Figure 8. Safety Relief Pressure Valve

(Rubber Check Ball Release)