Mg-30 pump — application – Multiquip MG30M2D User Manual

Page 26

PAGE 26 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

MG-30 PUMP — APPLICATION

Anytime it is necessary to uncouple or remove any part of

the delivery system, the manual pressure release plug must

be opened to relieve pressure in the system.

Pressure Relief Plug (Manual Operation)

Purpose

To provide the capability that will

manually

release the pressure

in a material hose or line whenever the flow of material is restricted

for any reason, causing unsafe pressure to build up in the hose

or line.

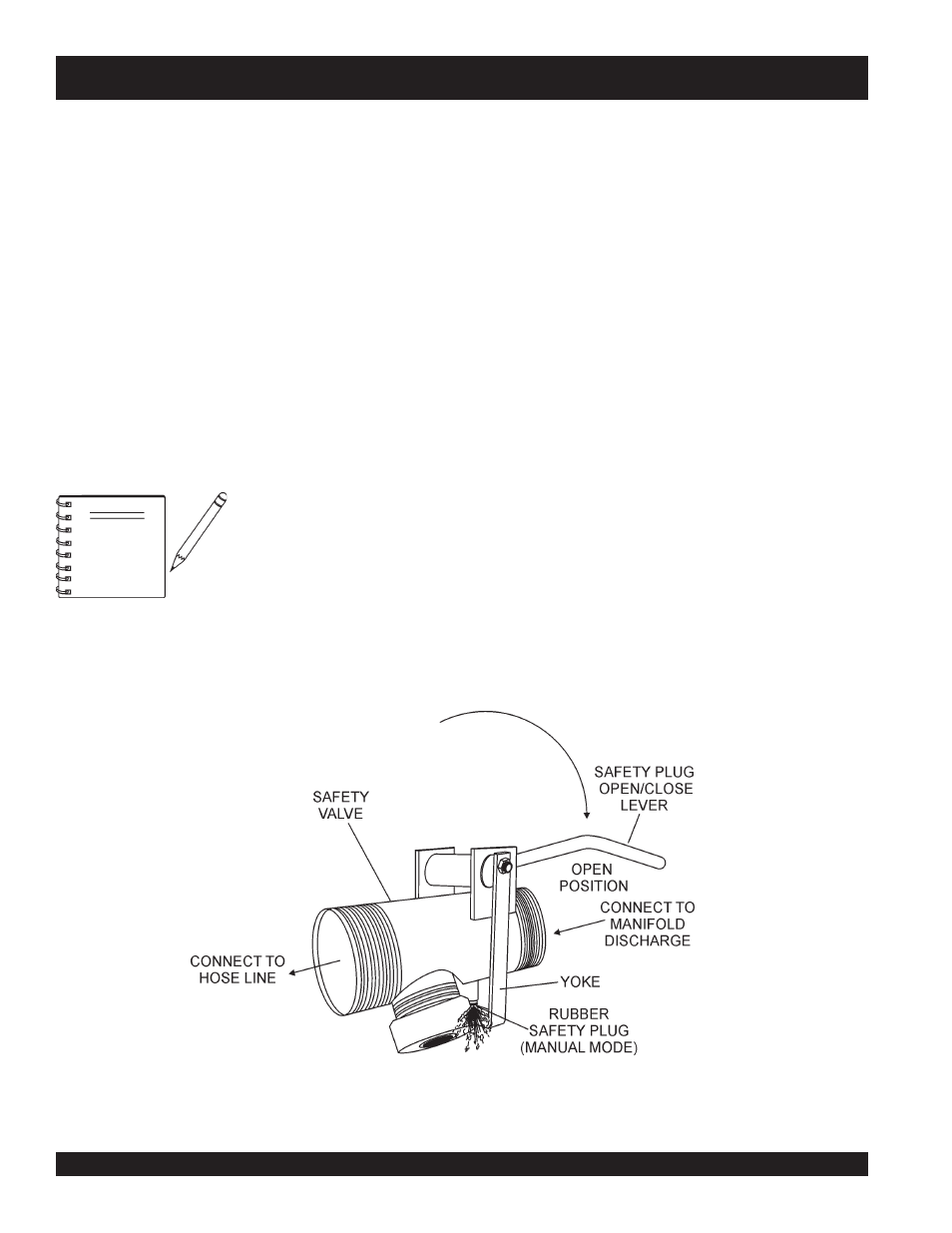

Safety Valve Placement (Manual)

Place the

safety relief pressure valve

(Figure 9) at the

discharge side of the plaster pump, ahead of the hose connection.

Located on the pressure relief valve is a

rubber pressure

release plug

(manual activation), the plug is held in position by

a steel clamp (

yoke

)

and is

activated by pulling the lever

downward

to release the pressure in the system.

This manual pressure release plug is to be used in conjunction

with the automatic release mechanism (

rubber check ball

).

ALWAYS

open the manual pressure

release plug before disconnecting

any part of the delivery hose, line or

clamp system.

NOTE

Before activating the manual pressure release

plug

the operator

must

do the following:

1. Stop the engine.

2. Warn all workers and bystanders to stand at least 20 feet

away from the pump and turn their heads away from the

pressure relief safety valve.

3. The operator shall position himself/herself beside the

pressure relief safety valve with his/hers back to the

pump.

4. Wearing safety glasses, reach down with one hand, grasp

the release lever on top of the safety valve.

5. Turn head away from the pressure release plug and lift lever

upwards

(

open)

.

6.

Remain facing away from the pressure relief valve until

counting up to 20, slowly. By that time, the material ejecting

under pressure will be slowly discharging. Work can resume

only after the material has been discharged for a minimum

of 20 seconds.

7. After correcting the problem that caused the excess pressure

in the system line, close the safety plug by pushing the plug

open/close lever

downward (

closed), and resume pump-

ing.

Figure 9. Rubber Safety Relief Pressure Plug