Mg-30 pump — pre-inspection (pump) – Multiquip MG30M2D User Manual

Page 37

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 37

MG-30 PUMP — PRE-INSPECTION (PUMP)

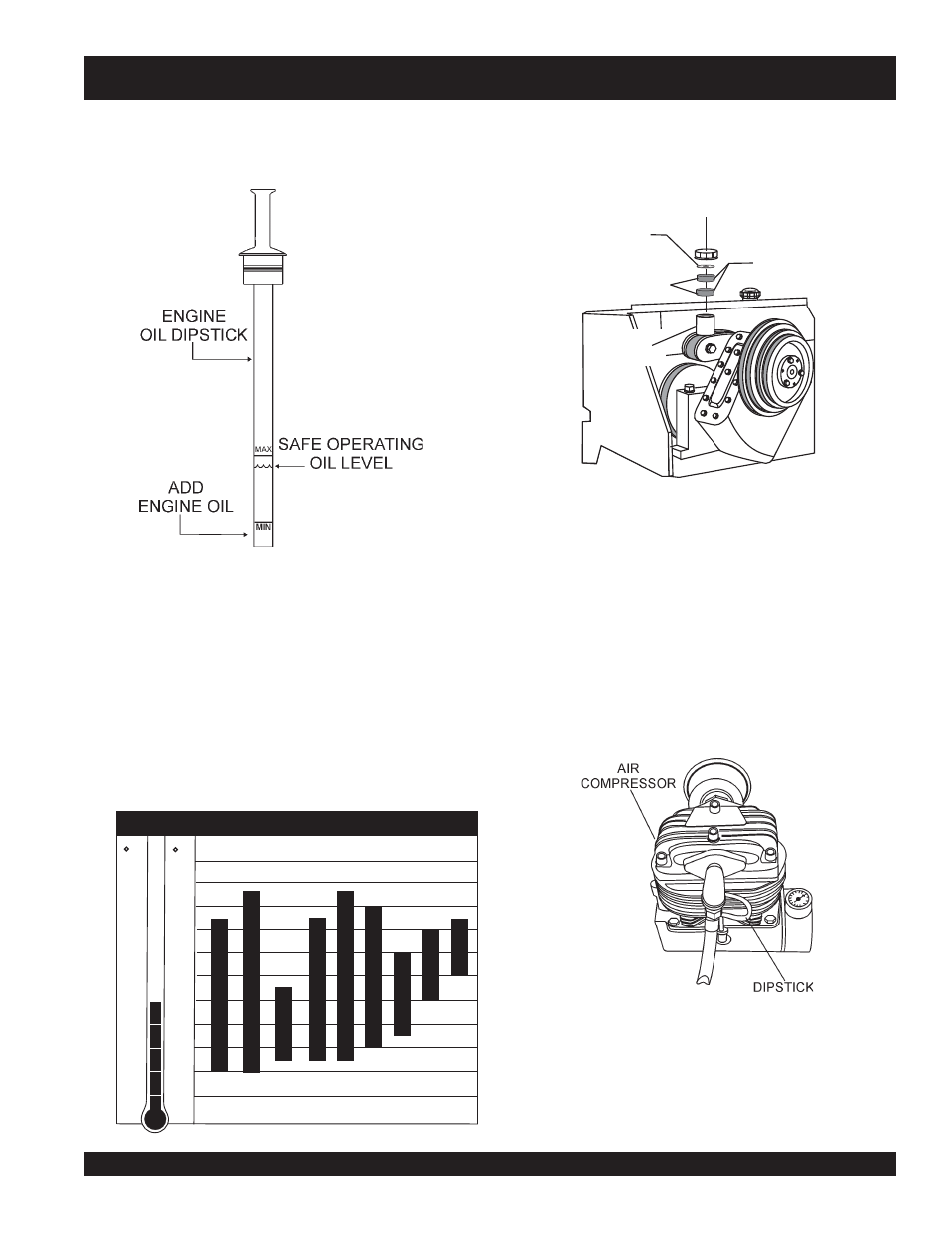

3. Verify that oil level (Figure 27) is maintained between

the two notches on the dipstick.

4. If the pump's engine oil is low, fill engine crankcase

with lubricating oil through filler hole, but DO NOT overfill.

5. The oil listed in Table 8 is recommended to ensure better

engine performance. Use class CD or higher grade motor

oil.

1. Make sure pump/engine is placed on level ground.

2. Pull the engine oil dipstick (Figure 27) from its holder.

Figure 27. Dipstick (Pump Engine)

CAM OILER FELT PADS

1.

Remove the cam oiler cap and flat washer as shown in Figure 28.

FELT

PADS

SOAK IN

30WT.

MOTOR OIL

FLAT

WASHER

CAP

CAM

OILER

2. Inspect the two felt pads that lay inside the cam oiler. The pads

should be saturated with 30 wt. motor oil. If pads are dry

saturate with 30 wt. motor oil.

3. Insert pads back into oiler and place flat washer on top and

tighten oiler cap securely.

COMPRESSOR OIL CHECK

1.

Remove the air compressor oil dipstick (Figure 29) from its

holder.

Figure 28. Cam Oiler (Pads)

2. Determine if the air compressor oil level is low (Figure 30),

add correct amount of oil to bring oil level to a normal safe

level. The compressor's crankcase capacity is 1.5 pints (.709

liters). See Table 7 for recommended oil type.

Figure 29. Dipstick Location (Air Compressor)

-40

-30

-10

-20

-22

-40

-4

-14

0

32

50

68

86

104

122

10

20

30

40

50

F

C

5W/30

5W/40

10W

10W/30

10W/40

15W/40

20W/20

30

40

OIL: SAE

Table 8. Oil Selection Chart