Mg-30 pump — mixer major components – Multiquip MG30M2D User Manual

Page 27

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 27

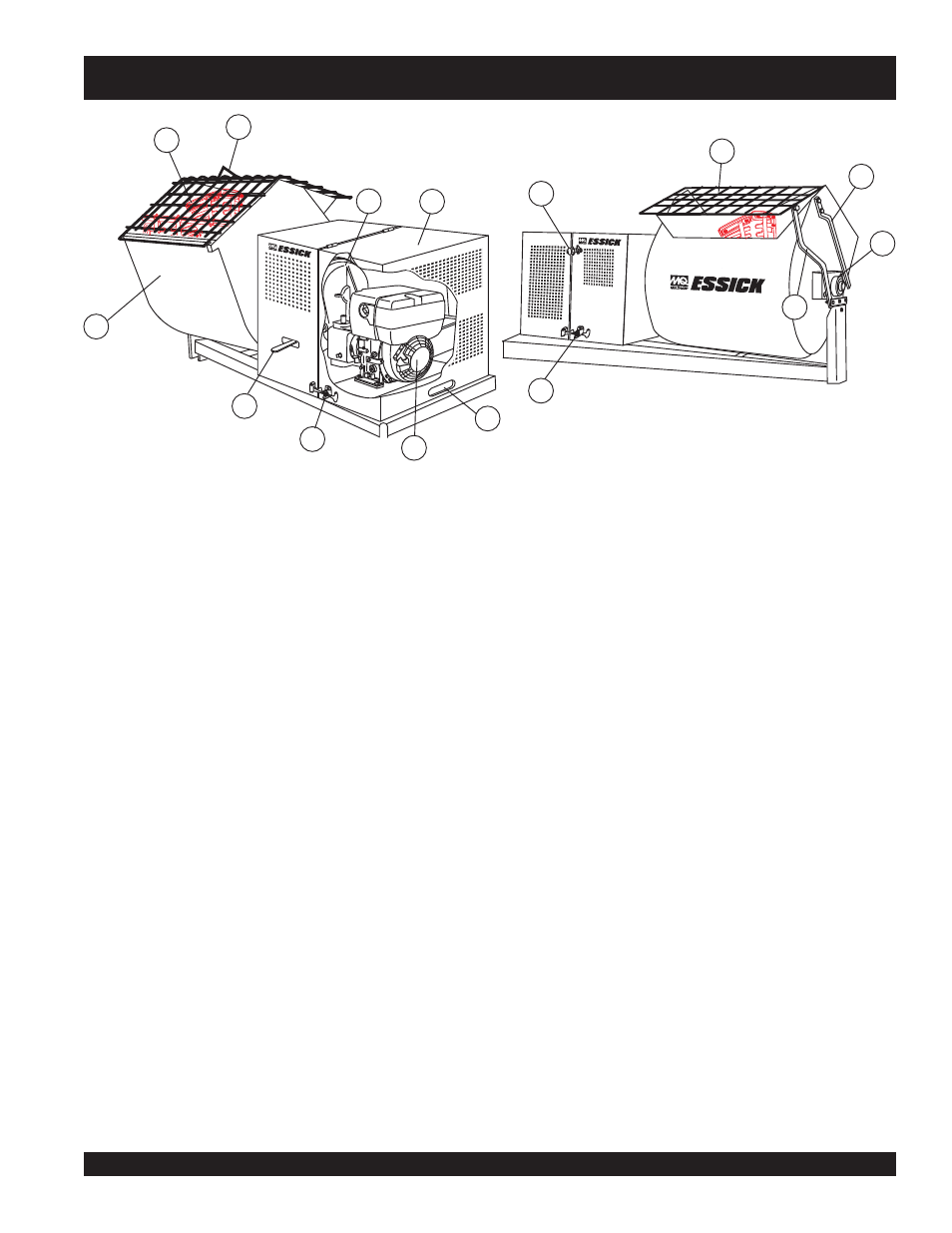

MG-30 PUMP — MIXER MAJOR COMPONENTS

Figure 10 illustrates the major components and controls of

the mixer.

1.

Mixing Drum — Made of

steel

. Mixing materials such as

concrete, mortar, plaster are to be placed into this drum for

mixing. Always clean the drum after each use. Drum

capacity is 12 cu. ft.

2.

Mixing Paddles — Used in the mixing of material. This

unit uses four different types of paddles to provide a fast

uniform mix.

3.

Bag Cutter— This feature allows compound mixing bags

to be opened easily, therefore allowing the contents of the

bag to fall directly into the mixing drum. Bag capacity is 3.5

to 4 bags.

4.

Transmission — Totally inclosed oil bath transmission.

5.

Engine Cover — Lift this cover to gain access to the engine

and transmission compartments.

6.

Engine — The mixer unit is powered by a Hatz Model

IB30, 8.5 HP

diesel

engine. See page 30 for engine

component definitions.

7.

Engine Cover Grip — Place hand inside grip then lift

upwards to raise cover. When lifting of the cover is required

make sure both rubber bunjee latches have been released.

8.

Rubber Latch — Use this latch to secure the engine

compartment cover.

8.

Clutch Lever — Push the clutch lever

forward

, toward

the tow (tongue) end of the mixer to engage clutch. Once

clutch is engaged paddle shaft will rotate. To disengage

clutch pull the clutch

backwards

towards the engine.

9.

Dump Handle — Pull this handle downward to dump the

contents of the drum. Push the handle upward to return the

drum to its vertical position.

10. Pivot Point/Zerk Fitting — There is, on each end of the

mixing drum a zerk grease fitting. These fittings lubricate

the dumping mechanism. Lubricate both fittings at least

twice a week.

12. Safety Grill Lock Handle — To prevent injury to hands

and arms, the safety grill should ALWAYS be locked when

the mixing of plaster or mortar is required. Also when

transporting the mixer the safety grill should be locked. The

safety grill should only be un-locked when cleaning of the

blades and drum is required.

13. Safety Grill — Provided for operator safety. This safety grill

is designed to keep hands and solid objects out of the

mixing drum when in use. This grill should be closed at all

times when pump is in use. DO NOT remove the grill or

grill opening bar. Keep the grill clean by washing it down

daily.

2

3

1

4

5

5

6

7

8

9

10

11

7

12

13

Figure 10. Mixer Major Components