3 low-level switch adjustment – MTS Model 506-62-72 Hydraulic Power Supply User Manual

Page 23

Service 3-11

Water control

adjustment

1.

Ensure that the temperature gage reads below 90

°

F (32

°

C).

2.

Start the HPS. Turn the water control adjustment screw (figure

above) fully counterclockwise.

3.

Monitor the temperature gage while the hydraulic fluid

temperature rises.

4.

When the fluid temperature reaches approximately 110

°

F (43

°

C),

turn the adjustment screw clockwise until water starts to flow, then

turn it counterclockwise until water flow stops.

5.

If the fluid temperature does not reach 115

°

F (46

°

C) turn the screw

a half-turn counterclockwise and note the effect after 15 minutes.

If the temperature exceeds 115

°

F (46

°

C), turn the screw clockwise.

3 . 2 . 3

Low-Level Switch Adjustment

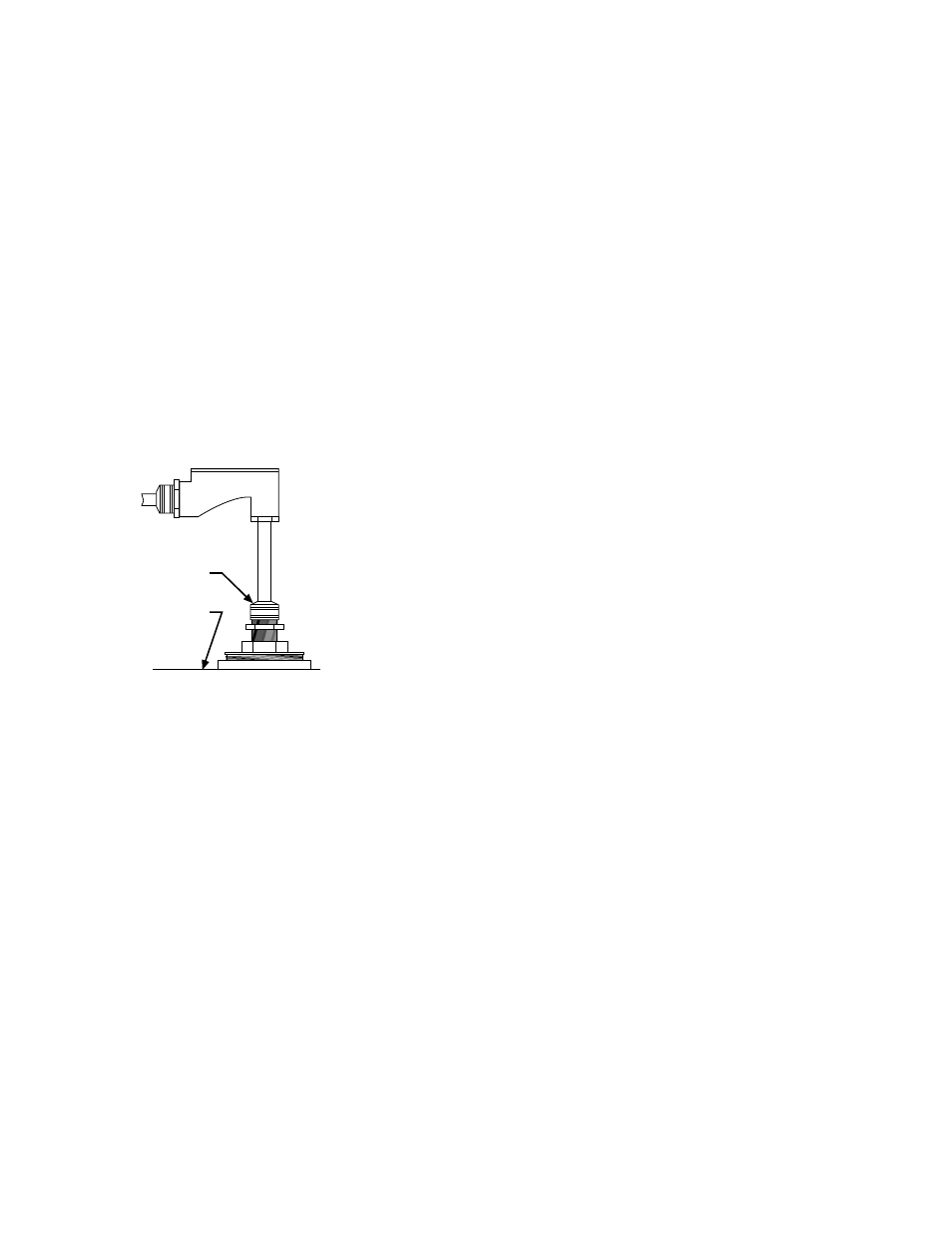

VW-G051

locknut

top of

reservoir

The low fluid-level switch turns off the HPS if there is an appreciable

loss of hydraulic fluid. The factory-adjustment coincides with the

bottom of the fluid level gage and does not normally require

readjustment. Perform the following steps if readjustment is necessary.

1.

With the HPS turned off, fill the reservoir to the correct fluid

level.

2.

Turn on the HPS and apply high pressure.

3.

See the figure on the left. Loosen the hand locknut on the stem of

the switch, and slowly raise the switch until the Low Fluid Level

indicator lights.

4.

Lower the switch about 1.5 in. (38 mm).

5.

Tighten the locknut.

6.

Reset any applicable interlock circuits.