2 two-wire start/stop control – Lenze MC1000 Series User Manual

Page 39

13435742_EDBM101_v24

35

15.2

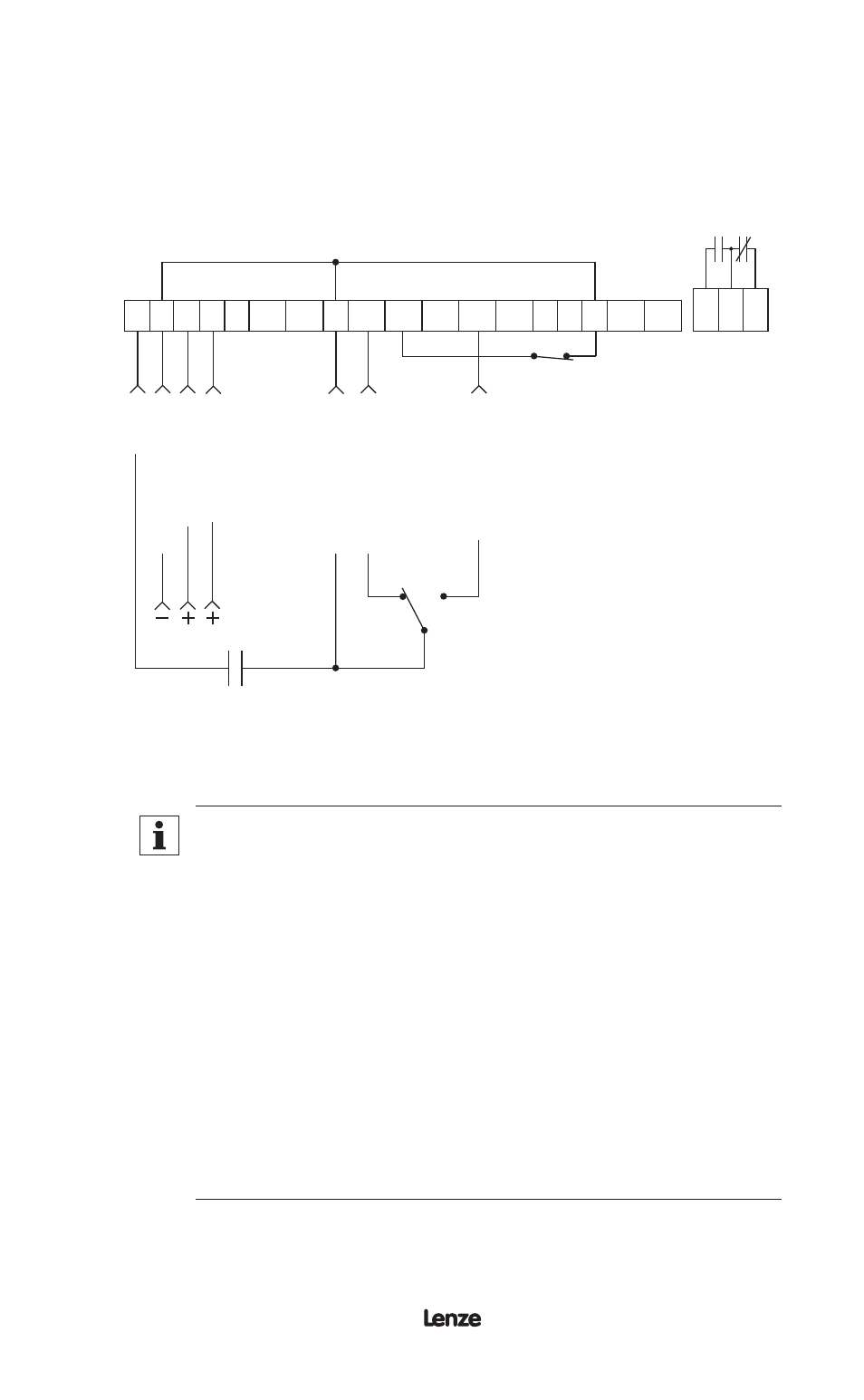

TWO-WIRE START/STOP CONTROL

Shown below is the wiring diagram for a typical two-wire start/stop control scheme,

using one maintained contact (such as that from a PLC) for RUN and STOP

commands. Close the contact to RUN, and open the contact to STOP. Also shown

is the wiring for a 0-10 VDC or 4-20 mA speed reference signal.

ST

OP

CIR

CUIT C

OMMON

0-10 VDC

INPUT

4-20 mA INPUT

CIR

CUIT C

OMMON

ST

AR

T FOR

W

ARD

MAINTAINED

RUN/STOP

CONTACT

1 2 5A 5B 6 10A

12A

RXA TXB

10B 2

13A 13B 13C 13D 14 15 2

16 17 18

ST

AR

T RE

VERSE

0-10 VDC or 4-20 mA

SELECT (see Note 3)

FWD

REV

(see Note 2)

The TB-2 terminals are internally tied together

NOTE

1. Close TB-1 to TB-2 to RUN, and open to STOP.

2. If REVERSE direction is required, ROTATION must be set to

FWD&REV, and TB-13C must be set to START REVERSE (refer

to Parameters: 27 - ROTATION, and 49 - TB-13C).

If REVERSE is not required, jumper TB-2 to TB-12A and

eliminate the FWD/REV switch.

3. Program TB-13A, 13B, or 13C to select the appropriate speed

reference signal that will control the drive speed (refer to

Parameters 47, 48, and 49). When that TB-13 terminal is closed

to TB-2, the drive will respond to the selected speed reference

signal. In the diagram above, TB-13A is programmed to select

either a 0-10 VDC or 4-20 mA signal.

4. If the contact closure is not made between TB-13A and TB-2 to

select a speed reference, the drive will default to MANUAL speed

control, which is determined by Parameter 29 - MANUAL.