1 variable torque vs. constant torque – Lenze MC1000 Series User Manual

Page 19

13435742_EDBM101_v24

15

CONSTANT TORQUE

CONSTANT HP

TORQUE

HORSEPOWER

HORSEPOWER

TORQUE

FREQUENCY (Hz)

TOR

QUE (%)

20

40

60

80

100

120

150

130

110

90

70

50

30

10

6.1.1

VARIABLE TORQUE VS. CONSTANT TORQUE

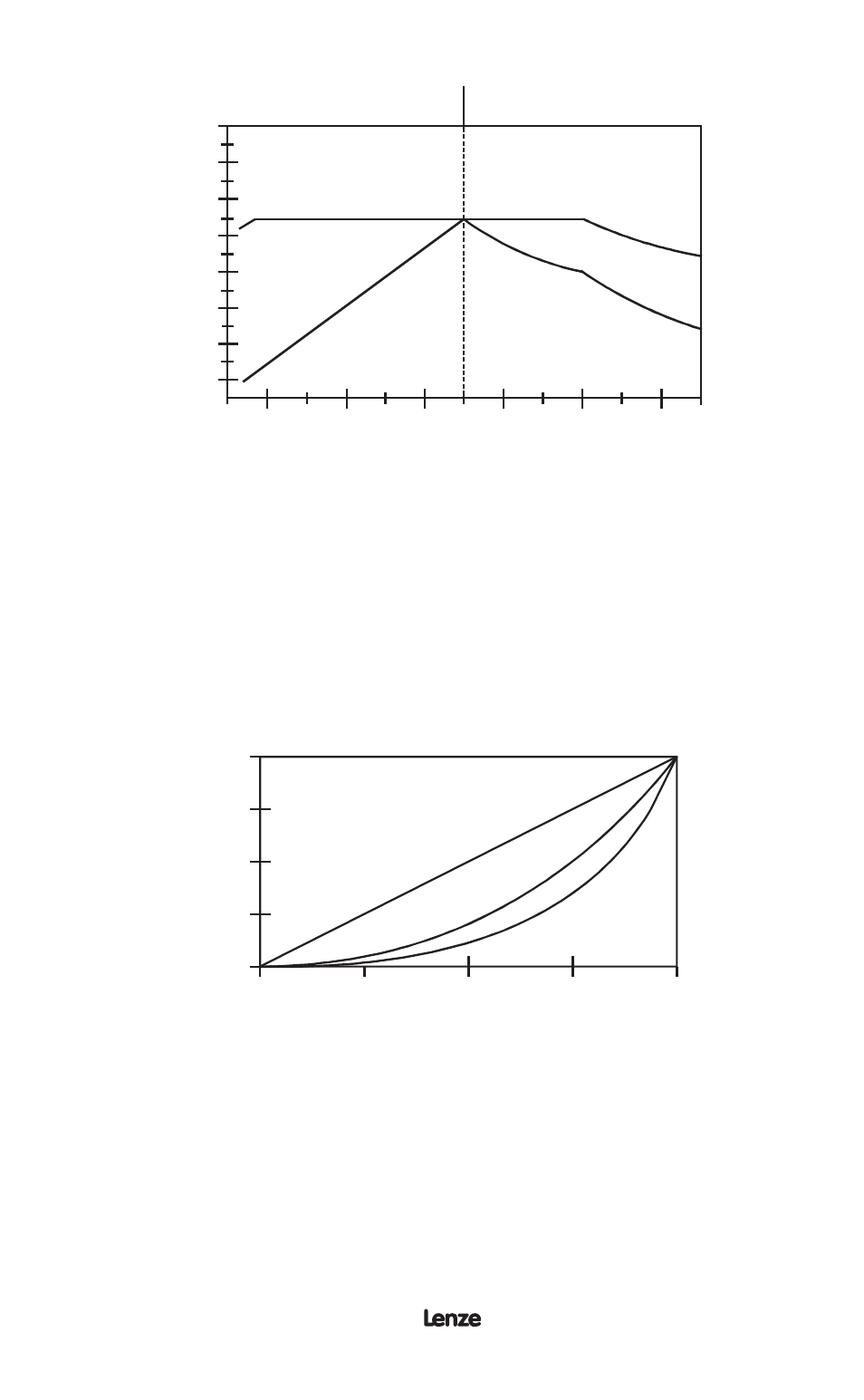

Variable frequency drives, and the loads they are applied to, can generally be

divided into two groups: constant torque and variable torque. Constant torque loads

include: vibrating conveyors, punch presses, rock crushers, machine tools, and

just about every other application that is not considered variable torque. Variable

torque loads include centrifugal pumps and fans, which make up the majority of

HVAC applications.

Variable torque loads are governed by the affinity laws, which define the relationships

between speed, flow, torque and horsepower. The diagram below illustrates these

relationships:

0%

25%

50%

75%

100%

100%

75%

50%

25%

0%

% SPEED

% T

OR

QUE

% HORSEPOWER

% FL

OW

“Variable torque” refers to the fact that the torque required varies with the square of

the speed. Also, the horsepower required varies with the cube of the speed, resulting

in a large reduction in horsepower for even a small reduction in speed. It is easily

seen that substantial energy savings can be achieved by reducing the speed of a

fan or pump. For example, reducing the speed to 50% results in a 50 HP motor

having to produce only 12.5% of rated horsepower, or 6.25 HP.

Variable torque drives usually have a low overload capacity (110% - 120% for

60 seconds), because variable torque applications rarely experience overload

conditions. To optimize efficiency and energy savings, variable torque drives are

usually programmed to follow a variable V/Hz ratio.