Roller axle assemblies, Hydraulic system, Tires – Landoll WFPC22-36 Wing Float Pulverizer User Manual

Page 47: Fasteners, Storage, Warning

MAINTENANCE

4-5

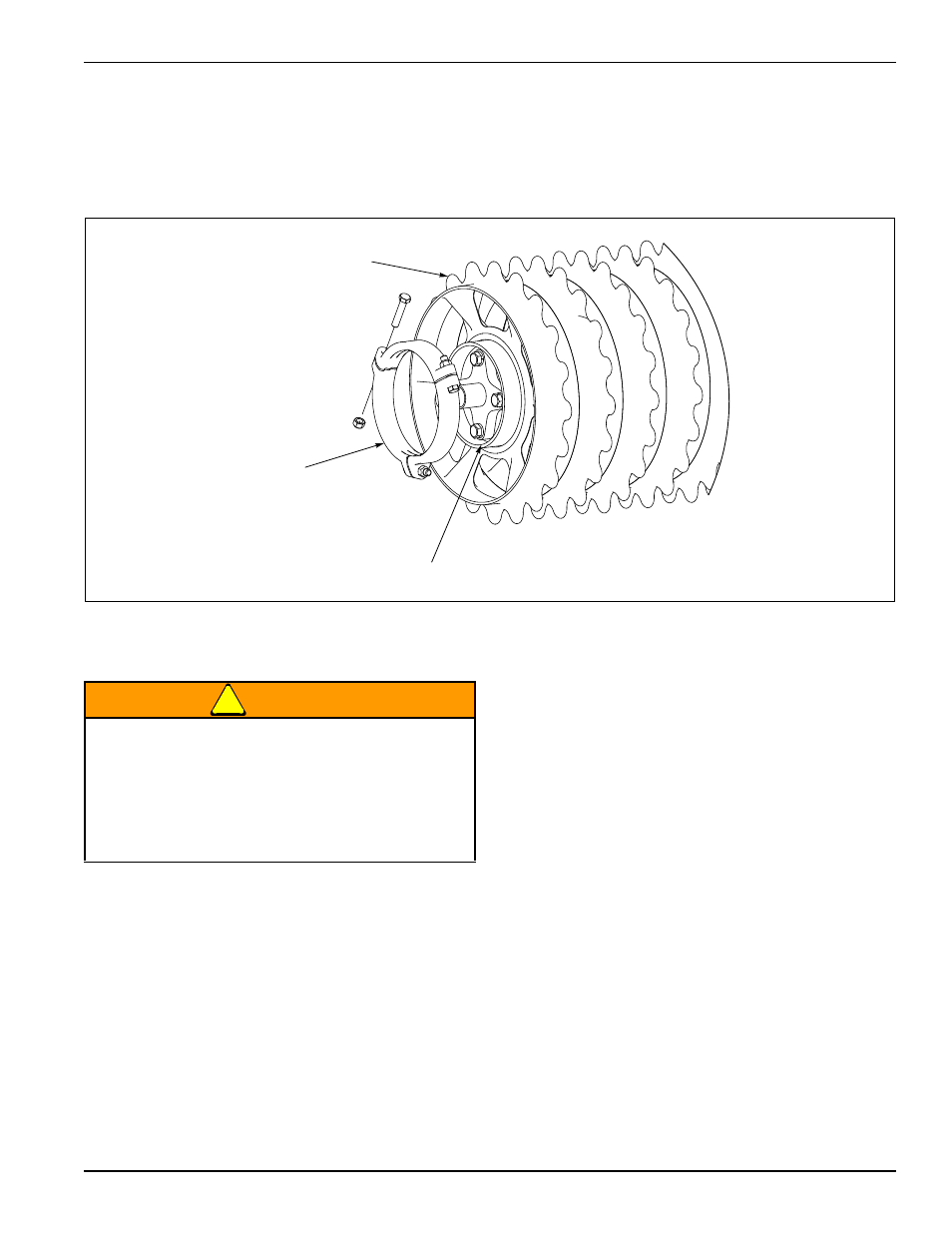

Roller Axle Assemblies

After an initial run of 5-10 hours, check the Roller Axle

Assemblies to insure that the wheels are tight to one

another. If not slide the wheels tight together and adjust

the Axle Clamps.

Tighten the Clamp bolts evenly to achieve equal spacing

between clamp section. Torque to 75 ft/lbs. Thereafter

check assemblies every 50-100 hours.

Figure 4-3: Roller Axle Assemblies

Hydraulic System

WARNING

Check the hydraulic lines and cylinders for leaks before

starting operation each day.

When the machine is not to be used for some time,

exposed portions of the cylinder rods should be cleaned

and covered with a thin coat of grease. This will prevent

corrosion which will damage cylinder seals.

Tires

All machines are shipped with 15 X 8 LB, 6 Bolt Wheels

which require 11L - 15, 8 Ply Rib Implemented Tires.

Inflate to 36 PSI. After several hours of use re-torque

Wheel Bolts to 80-85 ft/lbs.

Fasteners

Before operating your Brillion machine, check all

hardware for tightness. (See “General Torque

Specifications” on page 4-1.) as a guide.

After a few hours of use, check entire machine and

tighten any loose nuts or bolts. Daily or periodic checks

should be made thereafter.

When replacing bolts, be sure to use fasteners of equal

grade.

Storage

At the end of the season clean your machine for storage.

Avoid spraying high pressure washer directly at bearing

seals. Grease machine after washing to displace any

residual water. Repaint areas where paint has worn off.

Repair or replace any broken or damaged parts. Store in

a dry, protected place.

Wheel

Axle Clamp

Axle

Escaping fluid under pressure can be nearly

invisible and have enough force to penetrate the

skin causing serious injury. Use a piece of

cardboard, rather than hands to search for

suspected leaks. Wear protective gloves and

safety glasses or goggles when working with

hydraulic system.