3 what to do in case of problems – INFICON BPG400 ATM to Ultra-High Vacuum Gauge User Manual

Page 49

tina03e1-b (2004-02) BPG400 v1.om

49

• Pin approx. ш1.3 Ч 50 mm (e.g. a bent open paper clip)

The push button used for the adjustment at atmospheric pressure is also used for

the zero point adjustment (

→ 47).

Operate gauge for approx. 10 minutes at a pressure of

≤1×10

-4

mbar.

Insert the pin through the opening and push the button inside for at least

2 s.

The adjustment is done automatically and ends after 2 minutes.

The zero point of the gauge is now adjusted.

In the event of a fault or a complete failure of the output signal, the gauge can eas-

ily be checked.

• Voltmeter / ohmmeter

• Allen key, size 2.5 mm

• Spare sensor (if the sensor is faulty)

The output signal is available at the sensor cable connector (Pin 2 and Pin 12).

In case of an error, it may be helpful to just turn off the mains supply and

turn it on again after 5 s.

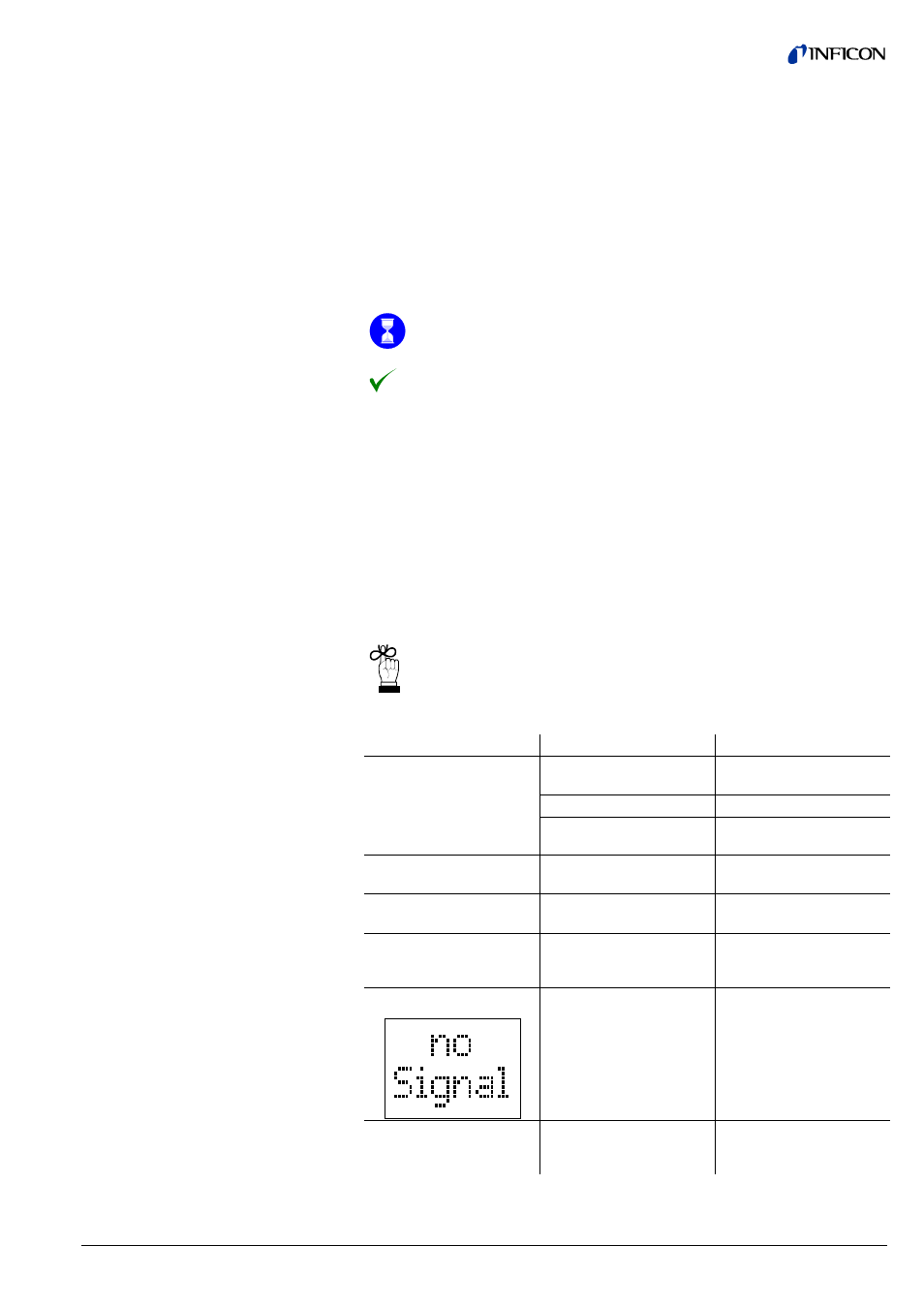

Problem

Possible cause

Correction

Output signal

permanently

≈0V

Sensor cable defective or

not correctly connected

Check the sensor cable

No supply voltage

Turn on the power supply

Gauge in an undefined

status

Turn the gauge off and on

again (reset)

Output signal

≈0.3 V

(Display: error = 8)

Hot cathode error

(sensor faulty)

Replace the sensor

(

→ 51)

Output signal

≈0.5 V

(Display: error = 9)

Pirani error

(sensor defective)

Replace the sensor

(

→ 51)

Output signal

≈0.5 V

Electronics unit not

mounted correctly on

sensor

Check the connection

Display:

Internal data connection

not working

Turn the gauge off and on

again after 5 s

Replace the electronics

unit

Gauge does not switch

over to BA at low pres-

sures

Pirani zero point out of

tolerance

Carry out a zero point

adjustment (

→ 48)

Required tools

Procedure

6.3 What to Do in Case of

Problems

Required tools / material

Troubleshooting (BPG400)