INFICON BPG400 ATM to Ultra-High Vacuum Gauge User Manual

Page 20

20

tina03e1-b (2004-02) BPG400 v1.om

For reasons of compatibility, the expression "sensor cable" is used for all

BPG400 versions in this document, although the pressure reading of the

gauges with fieldbus interface (BPG400-SD, BPG400-SP or

BPG400-SR) is normally transmitted via DeviceNet, Profibus or RS485.

The sensor cable is required for supplying all BPG400 types with power.

In connection with the gauges with fieldbus interface (BPG400-SD,

BPG400-SP and BPG400-SR), it also permits access to the relay con-

tacts of the switching functions (

→ 21, 44).

The application and length of the sensor cable have to be considered when deter-

mining the number and cross sections of the conductors (

→ 9).

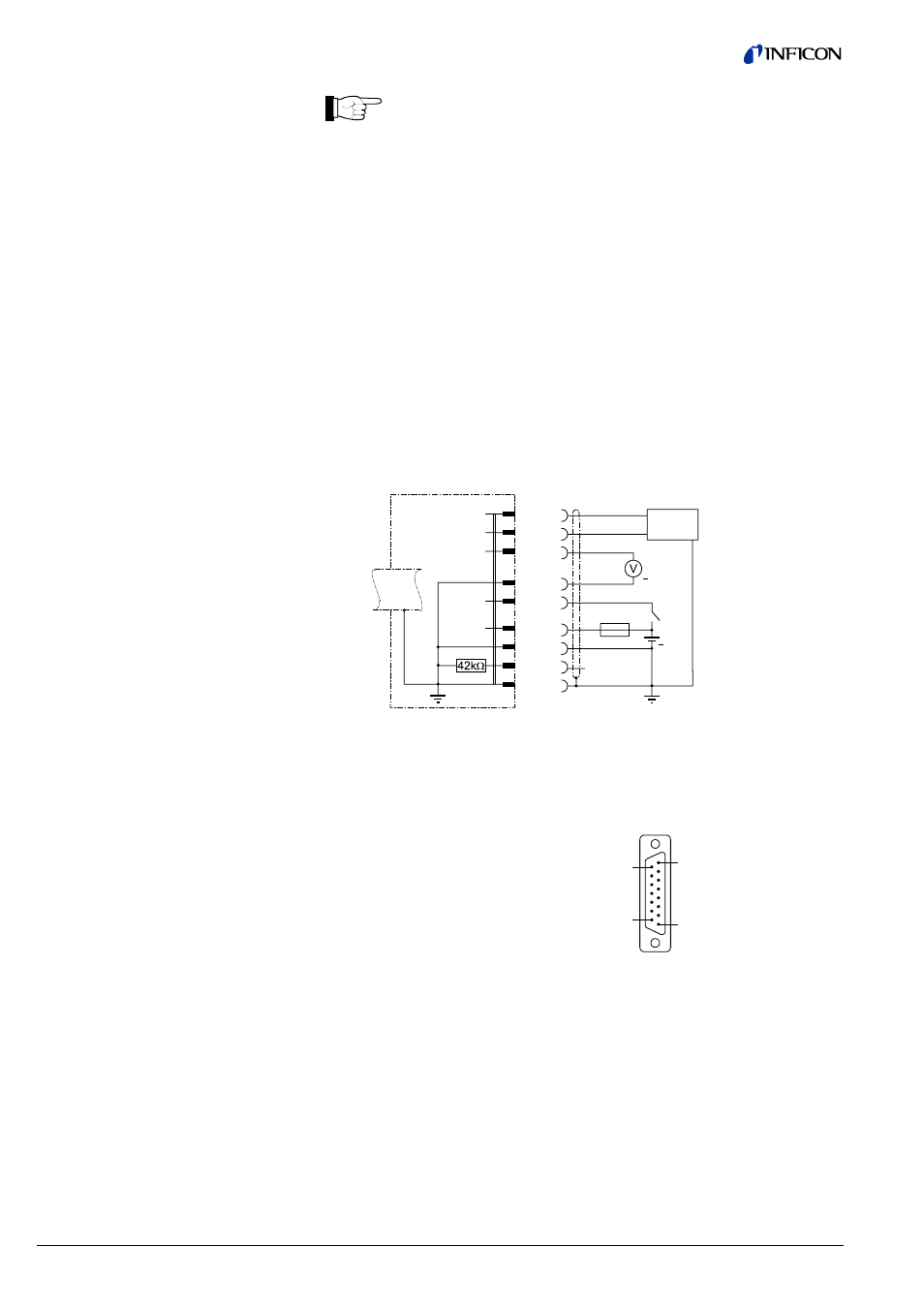

Open the cable connector (D-Sub, 15 pins, female).

Prepare the cable and solder/crimp it to the connector as indicated in the

diagram of the gauge used:

Electrical connection

Pin 2 Signal output (measuring signal)

Pin 5 Supply common, GND

Pin 7 Degas on, active high

Pin 8 Supply

Pin 10 Gauge identification

Pin 12 Signal common, GND

Pin 13 RS232C, TxD

Pin 14 RS232C, RxD

Pin 15 Shielding, housing, GND

8

9

1

15

+24 VDC

+24 VDC

Pins 1, 3, 4, 6, 9 and 11 are

not connected internally.

0 … +10 V

D-Sub, 15 pins

female,

soldering side

TxD

BPG400

RxD

Measuring

signal

Degas

+Ub

13

14

2

12

7

8

5

15

+

1.25AT

Identification

10

RS232C

+

24 V

3.2.2.1 Making an Individual

Sensor Cable

Cable type

Procedure

Sensor cable connection

BPG400