Enerpac ATM-4 User Manual

Page 7

7

13.0 TROUBLESHOOTING

PROBLEM 1: THE SCREW BOLT FEELS TIGHT TO

ROTATE.

SOLUTION: Ensure there is grease present on

screw bolt.

PROBLEM 2: THE FRICTION PAD ON THE SWIVEL,

AT THE BASE OF THE SCREW BOLT,

IS ROTATING ON THE FLANGE

CIRCUMFERENCE.

Note: The tool should not be used

if the friction pad is rotating on the

flange circumference.

CAUSE:

The swivel bearing is dirty or seized.

SOLUTION: The swivel should be stripped down,

cleaned, greased and reassembled.

If the problem still occurs replace

the swivel assembly (see repair parts

sheet).

PROBLEM 3: THE FRICTION PAD IS SLIDING ON

THE FLANGE CIRCUMFERENCE AS

THE JOINT IS ALIGNING.

CAUSE:

Grit or dirt on wing, roller bearings

require greasing. The tool has reached

full extension.

SOLUTION: Ensure the rollers are rotating freely

on the wing of the tool as it extends

out. If they are not, strip tool, clean

and grease rollers and wing. (see

paragraph 12.0, Lubrication and

Maintenance).

If tool has reached full extension, the

joint will most likely be outside of the

ATM-4 range.

PROBLEM 4: THE TOOL IS ATTACHED AND

APPEARS TO BE FUNCTIONING

PROPERLY, BUT THE JOINT WILL

NOT ALIGN.

CAUSE:

Hidden obstruction on the joint or

surrounding pipe, the load required to

align the joint is greater than that of

the ATM-4 (i.e. 4 Ton [40 kN]).

SOLUTION: a. Check the area around the joint for

obstructions.

b. It may be that the required pressure

to align the joint is greater that the

4 ton [40 kN] capacity of the tool.

In this instance another method to

align the joint should be adopted.

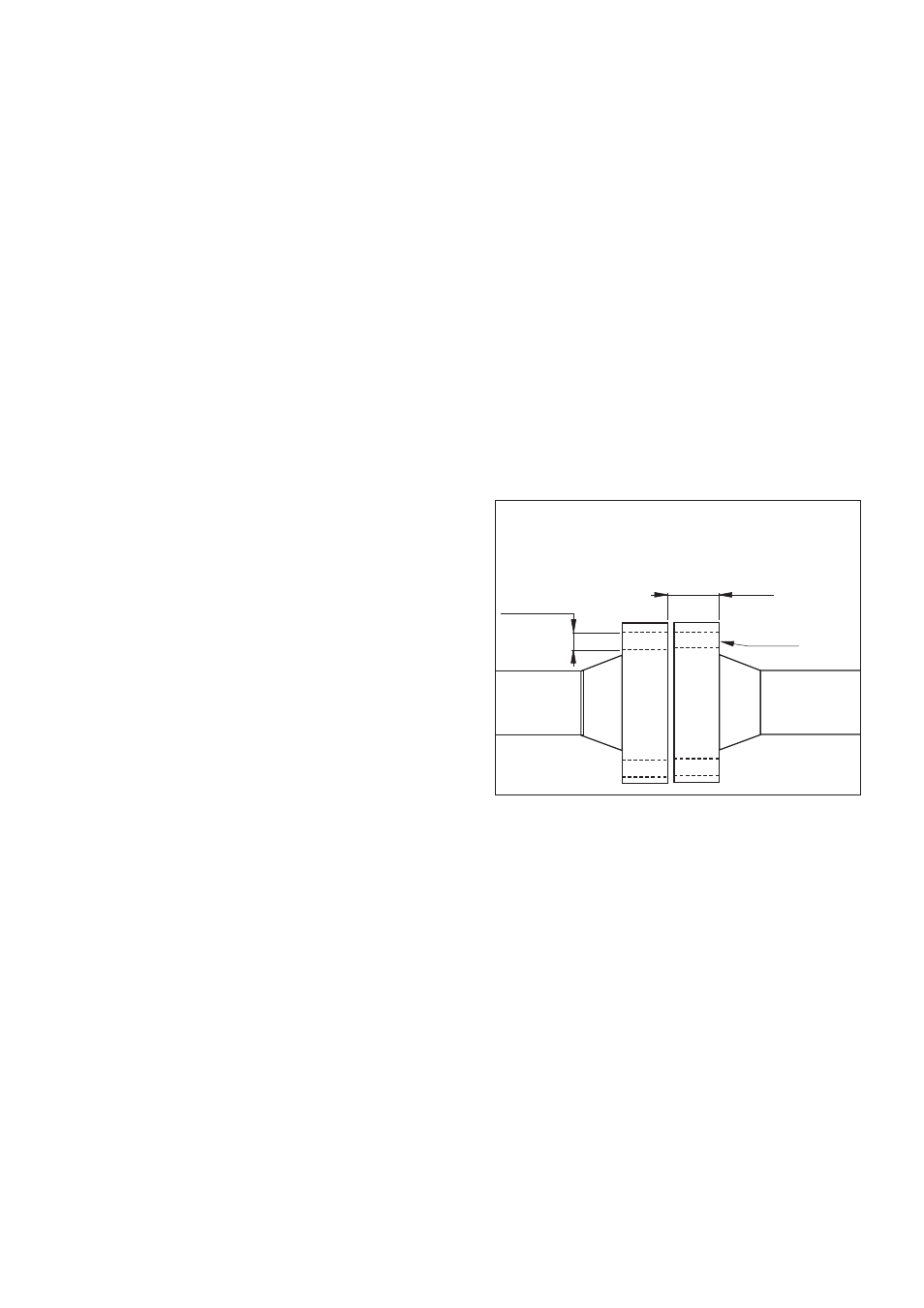

14.0 APPLICATION DIMENSIONS

Fig. 17

Min. bolt hole size

0.95 inch [24 mm]

Min. distance 1.18 inch [30 mm]

Max. distance 5.23 inch [133 mm]

Hook into this

bolt hole