Enerpac ATM-4 User Manual

Page 6

8.0 VERTICAL OPERATION

The set-up and operation of ATM-4 in the vertical

position remains the same as steps 1 thru 5 in

section 6.0 (see Fig. 15).

Fig. 15

USING THE ATM-4 ON A

VERTICAL LINE

9.0 DISMANTLING THE ATM-4

• Once alignment is achieved, all work on the joint

finished, and bolt-up completed (apart from the

bolt hole in which the ATM-4 is housed), the tool

can be dismantled by reversing steps 1 thru 5 in

paragraph 6.0.

• Care should be taken not to drop any of the

component parts when removing them from the

aligned joint. This action will prevent injuries to

either the operator’s lower limbs, or to passers-

by.

10.0 INSPECTION AND EXAMINATION

• After finishing the job and before the ATM-4 is

placed back into service

,

the completeness of the

tool must be established and items examined to

ensure that they are serviceable.

• Any missing or damaged items are to be replaced

as soon as possible and prior to the tool being

used again.

• Grease all moving parts regularly Refer to section

12.0, Lubrication and Maintenance.

• Ensure rollers and pins remain grit free.

• Return all items to the carrying case when not in

use.

11.0 STORAGE

• The ATM-4 should be stored in a cool dry place.

• Machined surfaces are to be smeared with

Mobilgrease XHP ™ 222 Special grease or an

equivalent good quality high load bearing grease.

12.0 LUBRICATION AND MAINTENANCE

Use Mobilgrease XHP ™ 222 Special grease or an

equivalent good quality high load bearing grease.

Maintaining the Tool

Always ensure the screw bolt is lubricated before use.

This will enhance the tool’s performance and lifetime.

On the base of the screw bolt within the swivel

is housed a thrust bearing which should be free

running and lubricated regularly.

Set the torque wrench to the lowest setting after

each use and for storage.

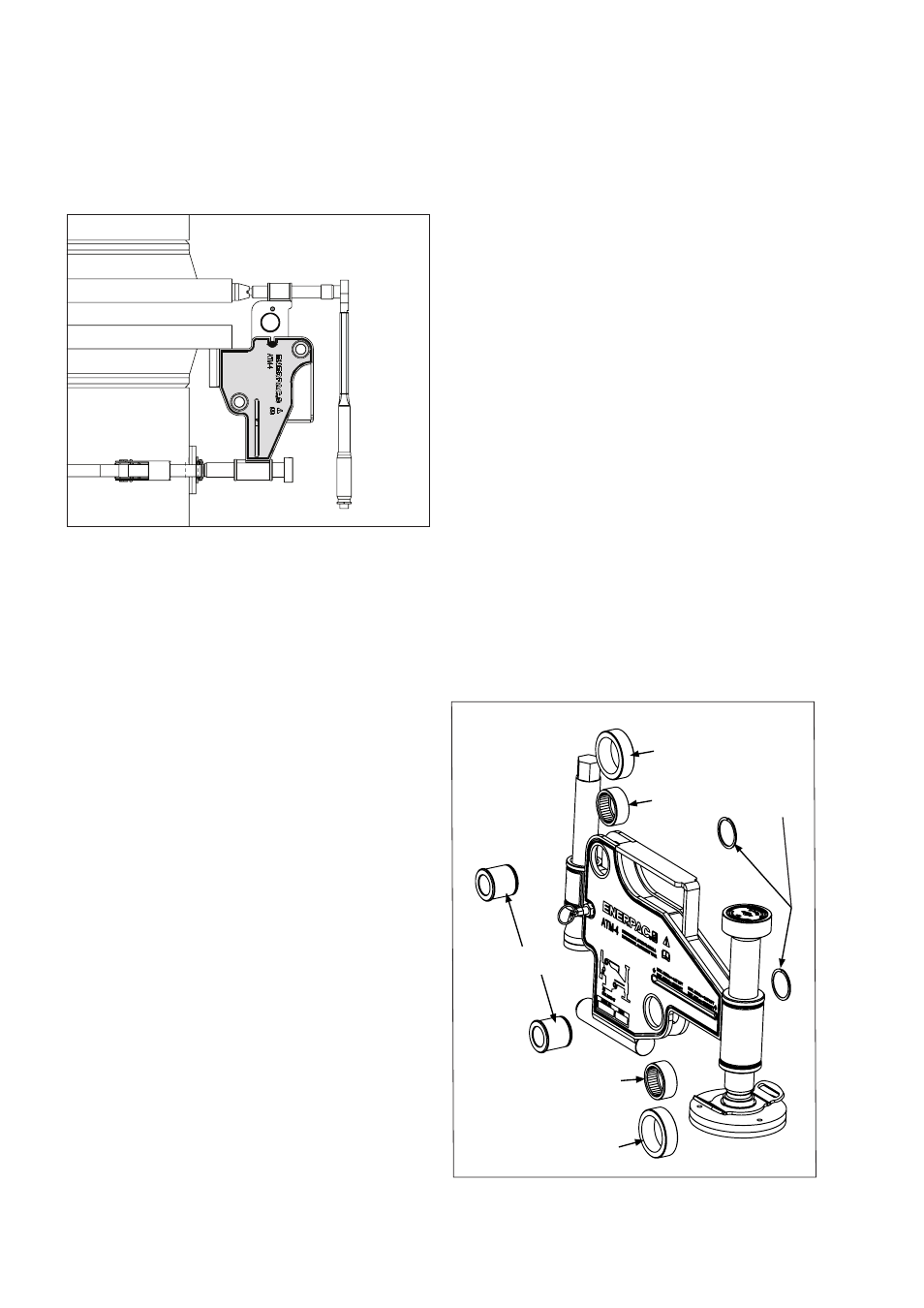

Cleaning and lubrication of internal parts

(see Fig. 16)

STEP 1. Place tool upright on a work bench.

STEP 2. Using a flat blade screwdriver, lever out

the end of each spiral clip. Then, rotate

them counter clockwise to remove.

STEP 3. Slide the roller shafts out in order to remove

the rollers and bearings for examination.

STEP 4. Inspect the roller shafts, rollers and bearings

for damage. If there is no damage present,

they can then be cleaned, greased and

reassembled (reverse steps 1 through 3).

Fig. 16

SPIRAL

CLIPS

ROLLER

SHAFTS

ROLLER

NEEDLE

BEARING

ROLLER

NEEDLE

BEARING

6