Enerpac ATM-4 User Manual

Page 4

4

6.0 INSTALLATION AND OPERATION

POINT OF MAX.

MISALIGNMENT

POINT OF MAX.

MISALIGNMENT

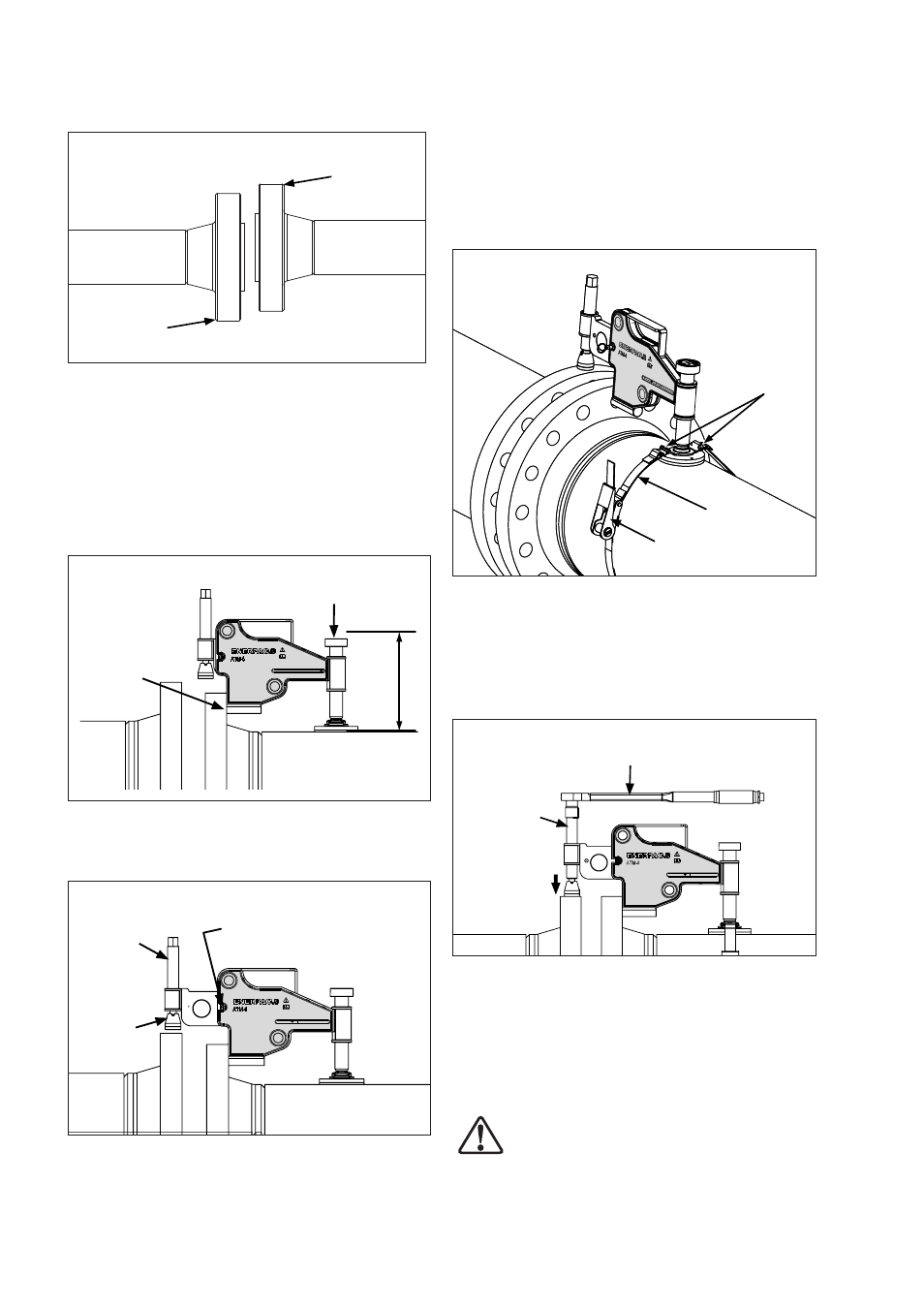

Fig. 6

1. Determine

the

maximum

points

of

misalignment. In the example shown in Fig. 6

example, the maximum points are on the top or

bottom of the joint, as illustrated by the arrows.

2. Guide the lift hook of the tool into the bolt hole at

the maximum point of misalignment. Then, adjust

the drop leg down onto the pipe by turning the

adjusting knob in the clockwise direction (see

Fig. 7).

LIFT

HOOK

DROP LEG

ADJUSTING KNOB

PARALLEL

Fig. 7

Note: The tool should be held up level within the

bolt hole during adjustment. The tool must remain

parallel to the pipe at all times.

Fig. 8

WING LOCK PIN

SCREW

BOLT

SWIVEL

3. Pull out the wing lock pin and extend the wing

over to the opposite flange. Then, rotate the screw

bolt onto the surface of the opposite flange (See

Fig. 8).

Ensure that tool is sitting level and that the friction

pad on the base of the swivel is in full and even

contact with the surface of the opposite flange.

Fig. 9

BUCKLE

STRAP

RATCHET

4. Attach the hook of the strap through one of the

slots on the buckle (located above the drop leg

pad). Place the hook of the ratchet through the

other slot on the opposite side of the buckle.

Feed the end of the strap through the ratchet and

tighten. (see Fig. 9).

Fig. 10

SCREW

BOLT

TORQUE WRENCH

5. Using the supplied torque wrench and 22 mm

socket, tighten the screw bolt in a clockwise

direction until the flanges come into alignment,

and bolts can be inserted. (see Fig. 10).

Note: The torque wrench and 22 mm socket supplied

with the tool is preset to apply a maximum force of

50 ft. lbs. [68 Nm].

CAUTION: Only use torque wrench

supplied with ATM-4.