Main feedback cable (feedback a) – ElmoMC ExtrIQ Digital Servo Drives-Eagle User Manual

Page 33

Eagle Installation Guide

Installation

MAN-EAGIG (Ver. 1.902)

33

3.4.3.

Feedback Control and Communication Cable Assemblies

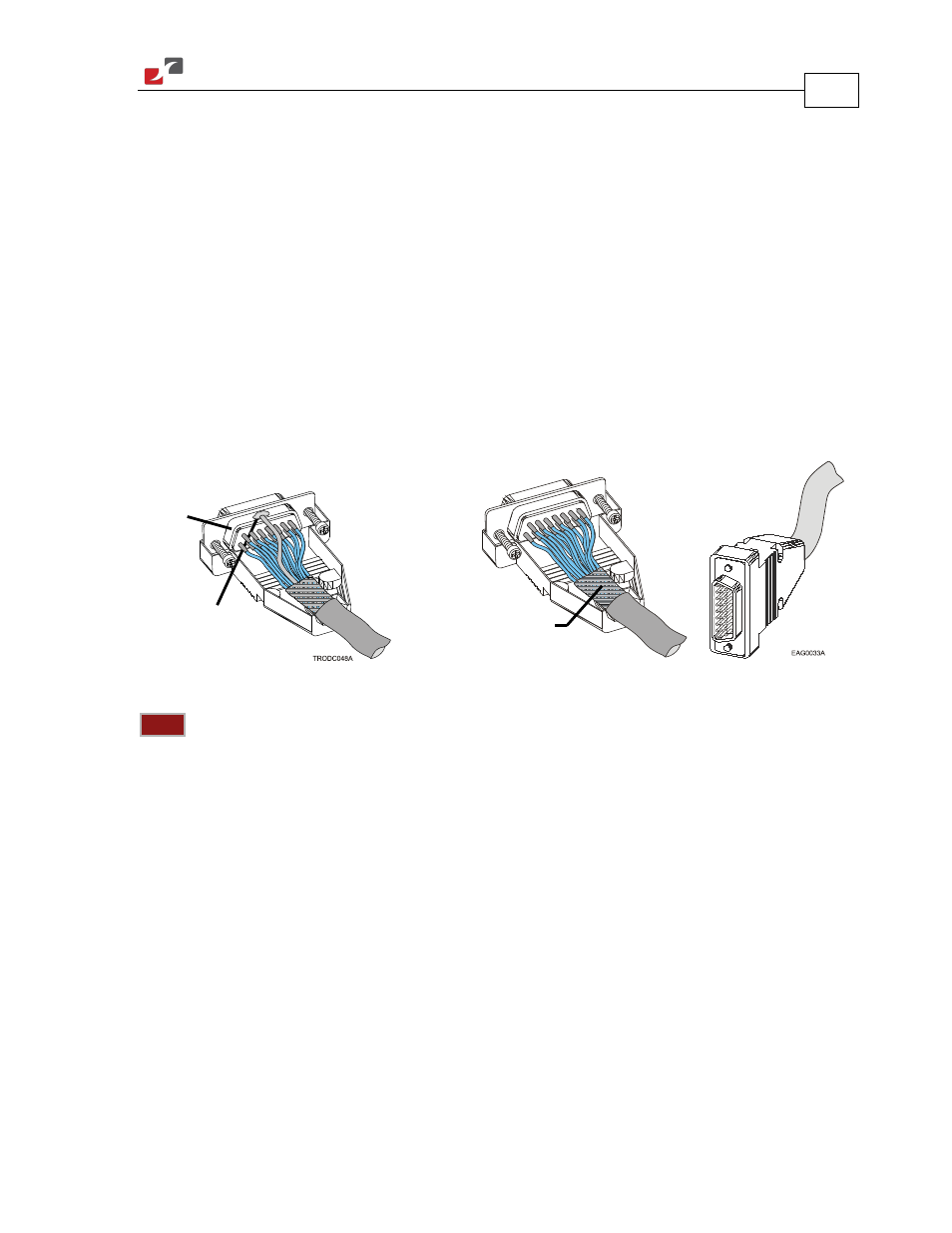

The Eagle features easy-to-use D-Sub type connections for all Control and Feedback cables.

Instructions and diagrams describing how to assemble those cables are presented below.

1.

Use 24, 26 or 28 AWG twisted-pair shielded cables (24 AWG cable is recommended). For best

results, the shield should have aluminum foil covered by copper braid.

2.

Use only a D-Sub connector with a metal housing.

3.

Ideally, solder the drain wire to the connector body as shown in Figure 11.

However, the shield may also be attached without soldering, as long as the braid shield is in

tight contact with the metal housing of the D-type connector.

4.

On the motor side connections, ground the shield to the motor chassis.

5.

On controller side connections, follow the controller manufacturer’s recommendations

concerning the shield.

Figure 11: Feedback and Control Cable Assemblies

Note:

All D-Sub type connectors, used with the Eagle, should be assembled in this way.

3.4.4.

Main Feedback Cable (Feedback A)

The main feedback cable is used to transfer feedback data from the motor to the drive.

The Eagle accepts the following as a main feedback mechanism:

•

Incremental encoder only

•

Incremental encoder with digital Hall sensors

•

Digital Hall sensors only

•

Interpolated Analog (Sine/Cosine) encoder (option)

•

Resolver (option)

•

Tachometer & Potentiometer

•

Absolute Encoder

Make sure that the

braid shield is in tight

contact with the metal

housing

Connector

body

Drain wire

soldered to

the metal

housing