Warning – COATS 6450 3D User Manual

Page 19

Important: Always read and follow the information box instructions.

• 13

4.

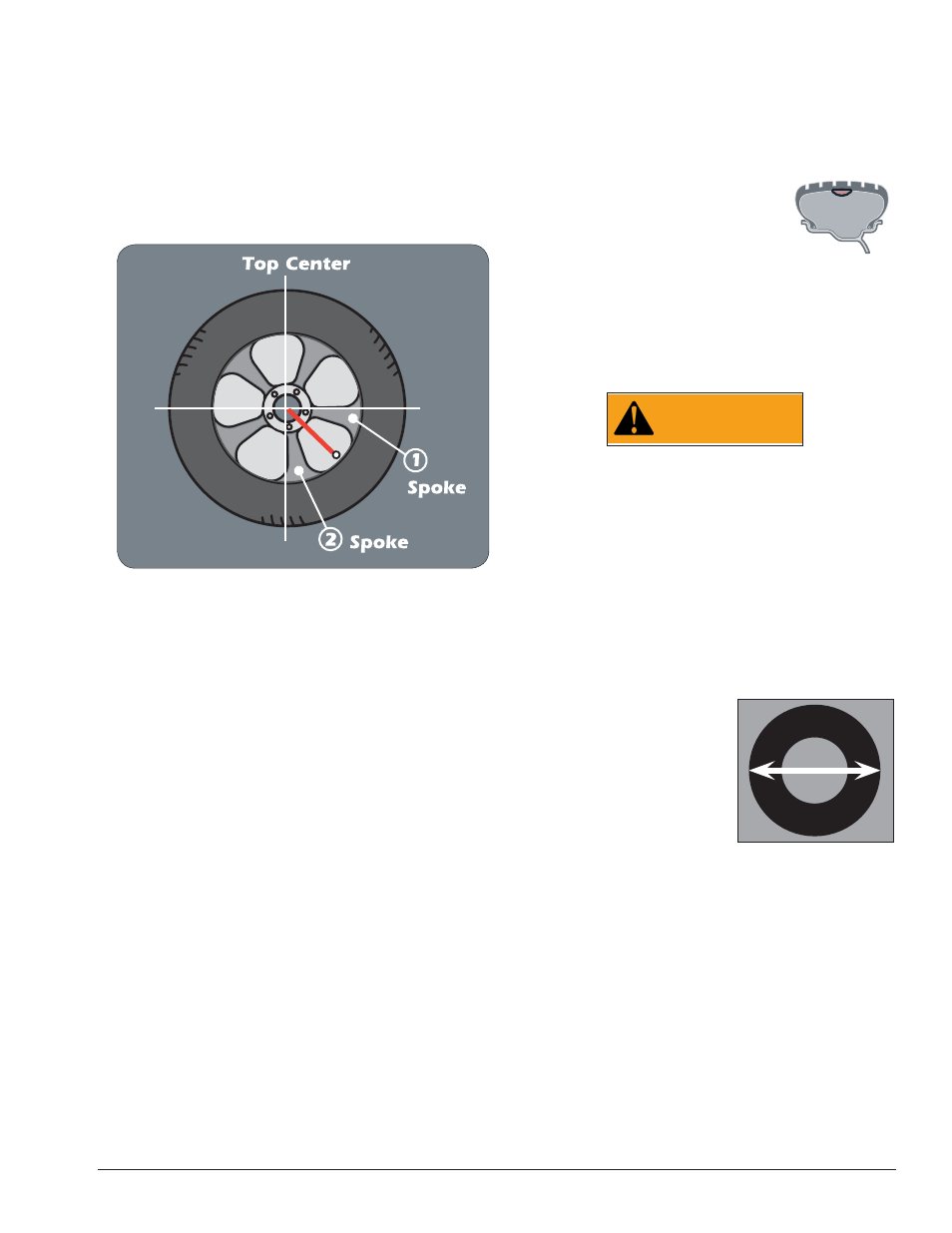

Rotate the wheel toward front so the laser locator

dot is behind the first spoke; press SPOKE 1 (indicator

illuminates).

5.

Rotate the wheel toward rear so the laser loca-

tor dot is behind the second spoke; press SPOKE 2

(indicator illuminates). Now at the spoke 2 location, the

outboard center bar stops blinking and the two bars on

either side blink.

Note: The laser locator dot will stop blinking.

Figure 15 - Spoke 1 And Spoke 2 Locations On Either Side Of

Original Outboard Weight Location

6.

Center and attach the spoke 2 outboard corrective

weight at the laser locator dot location (see figure 11

page 6).

7.

Next, rotate the wheel toward the spoke 1 location

until the outboard center bar stops blinking and the two

bars on either side blink.

Note: The laser locator dot will stop blinking.

8.

Center and attach the spoke 1 outboard corrective

weight at the laser locator dot location (see figure 11

page 6).

9.

Respin tire/wheel to check balance.

Patch Weight Balance - Use a static patch weight

balance when there is a very large unbalance in a tire

assembly or if a very large tire has a large unbalance.

A weighted balance pad (patch weight) is placed inside

the tire in the center to compensate for the large unbal-

ance.

Direct Select Weight position Patch

Static (weight location illuminates). At

this location place the corrective weight

amount at top-dead-center.

Have the following items handy: mea-

suring tape and various patch weight sizes.

Note: Before proceeding with Patch Weight Balance,

it is recommended that you use the Match Balance

(Optimization) procedure first, see page 16, in order to

use the smallest patch weight.

WARNING

The Patch Weight Balance involves the loos-

ening of tire beads and the inflation of a

tire. Training is necessary in tire changer

operation and understanding the dangers

involved during bead seating and tire infla-

tion before attempting this stage of the

Patch Weight Balance procedure. Read the

operators manual supplied with the tire

changer and consult a supervisor.

The patch weight balance steps are as follows:

1.

Direct Select Weight position PATCH STATIC. The

balancer automatically sets itself for a STATIC balance.

2.

Measure the outside tire

diameter, see figure 16, and

enter this diameter manually

using the keypad.

Figure 16 - Measure Outside Tire

Diameter

3.

Spin the wheel.

4.

Rotate the wheel until the center weight position

bar blinks. Next, mark the tire and rim at 12 o’clock.

Then remove the wheel assembly from the machine.

5.

Disassemble the tire and rim. Place patch weight

in the tire at location marked on the tire. Reassemble

tire and rim matching the marks on the tire and rim.

6.

Complete by balancing the wheel assembly follow-

ing normal procedures.

Outside

Diameter