Video balancer, Warning, Matching – COATS Series XR 1750, 1750-2D, 1750-3D, 1750-3DI Balancer User Manual

Page 24

18 •

Important: Always read and follow the on-screen operating instructions.

Video Balancer

Matching

A matching procedure may involve the loos-

ening of tire beads and the inflation of a tire.

Training is necessary in tire changer opera-

tion and understanding the dangers

involved during bead seating and tire infla-

tion before attempting this stage of a

matching procedure. Read the operators

manual supplied with the tire changer and

consult a supervisor.

Typically, if the static limit unbalance is exceeded, the

operator will choose Optimization (Match Balance) to

correct the situation.

To view the Static-on-Screen™ value, press the

key, select the SPECIAL FUNCTIONS option

, and

set the STATIC UNBALANCE DISPLAYED option

to ON. The Static-on-Screen™ reading, see page 9, will

appear in the upper left-hand side of the screen.

Optimization (Match Balance)

The Tire/Rim Weight Optimization procedure is used

to determine the best mating of tire and rim that will

result in the least amount of total unbalance of the

assembly. It requires two spins and two rotations of

the tire on the rim. Optimization may be needed when:

• The customer complains of ride problems.

• The balancer calls for total static weights in excess

of 3 ounces (85 grams) on passenger car tires.

Note: A high unbalance may indicate the improper

mounting of the assembly on the balancer, or a rim that

is out of round or misformed, or a tire with a bubble or

other problem. If the unbalance is excessive, it may be

prudent to replace the rim, the tire, or both. If either is

replaced, do not continue with optimization. Balance

the new tire and rim and evaluate the readings.

If you choose to use Optimization to correct for a con-

dition, such as a large static unbalance, then select the

key for the menu screen, and then select the

OPTIMIZATION (MATCH BALANCE) option

.

Follow the on-screen instructions for the TIRE/RIM

WEIGHT OPTIMIZATION procedure as outlined in

the following steps.

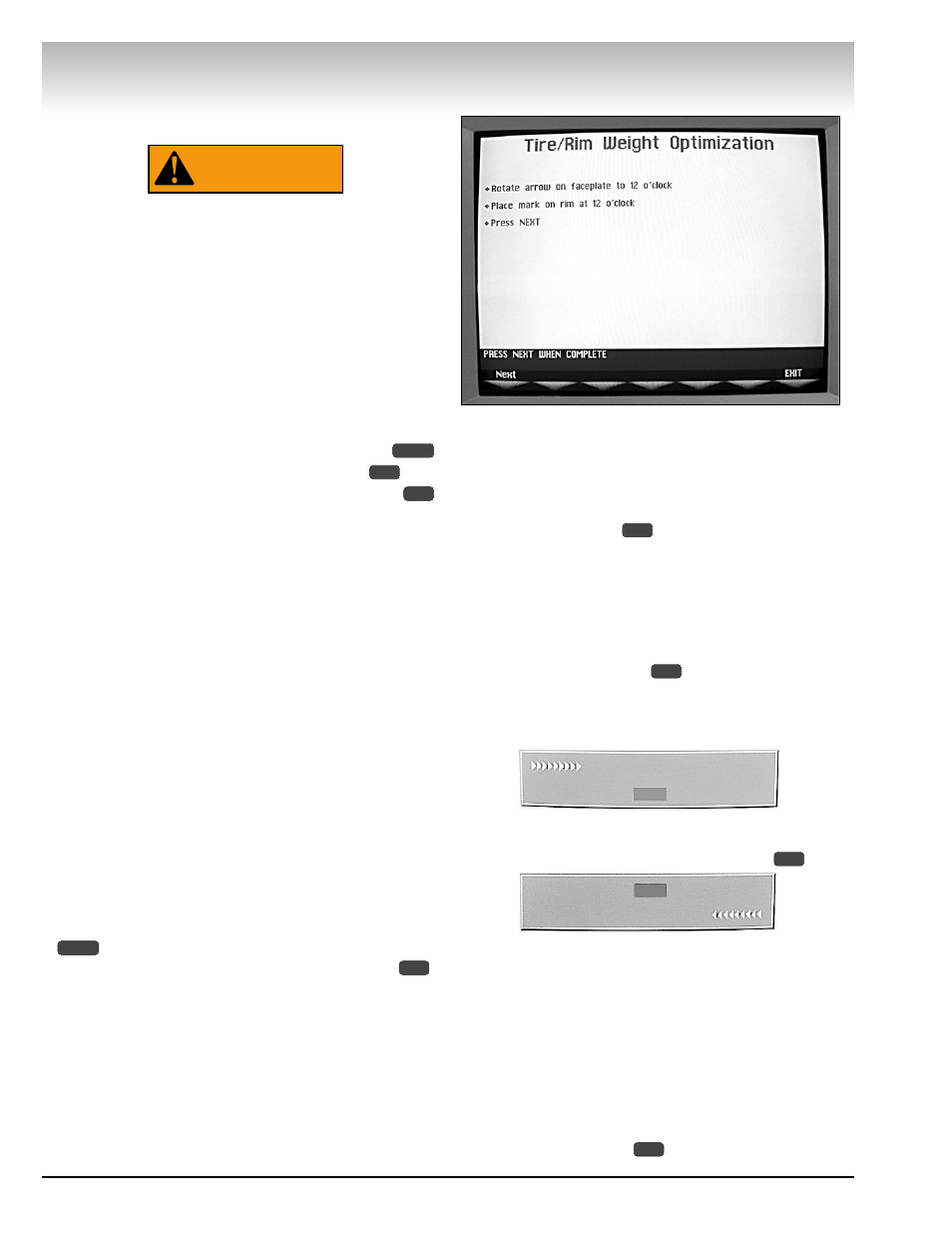

Figure 30 - Tire/Rim Weight Optimization Screen

Note: Use this procedure only after the wheel has

spun and weights are displayed.

1. Rotate arrow on faceplate to 12 o’clock. Place a

mark (backside of the wheel) on the rim at 12 o’clock.

Press the NEXT option

.

2. Remove the wheel assembly from the balancer.

3. Using a tire changer, rotate the tire 180 degrees

on the rim.

4. Replace wheel assembly on balancer and align the

faceplate arrow with the mark on rim. Lower the hood

and press the NEXT option

. The wheel spins.

5. Rotate the wheel until a red box appears at the

yellow arrows. Put a second mark (frontside of wheel)

on the rim at 12 o’clock.

6. Rotate the wheel until a red box appears at the

green arrows. Put a third mark (frontside of wheel) on

the tire at 12 o’clock. Press the NEXT option

.

Note: The rim unbalance and tire unbalance values

are displayed on the screen.

7. Remove wheel assembly from balancer.

8. Using a tire changer, align the mark on the rim

with mark on the tire.

9. Replace the wheel assembly on the balancer.

Align the faceplate arrow with the previous mark (back-

side) on the rim to check improvement or just continue

with step 10.

10. Press NEXT option

and balance the assembly

1

1

1

1

1

MENU

4

7

MENU

WARNING