3 sensor installation guidelines, Feature, 4 process piping considerations – CiDRA SONARtrac HD GVF-100 User Manual

Page 20

Copyright © 2006 CiDRA Corporation

Page 7-2

20675-02 Rev 01

7.3

Sensor Installation Guidelines

The following are general installation guidelines and recommendations

for installing a SONARtrac

TM

sensor.

•

Where necessary, get a Hot Work Permit prior to installation of

system.

•

Select locations with well-developed flow profiles.

•

Avoid installation locations directly after piping configurations that

cause flow jetting.

•

Install flow sensor upstream of control valves, “T”s, orifice plates,

and any other severe source of flow disturbance.

•

Locate the sensor upstream of pipe taps such as those used for

temperature and pressure sensors.

•

Good piping practices are required near flanges. This includes

good alignment of pipes, and properly sized and installed gaskets

that do not disturb the flow profile.

•

Contact your local distributor or CiDRA Technical Support if you

have questions.

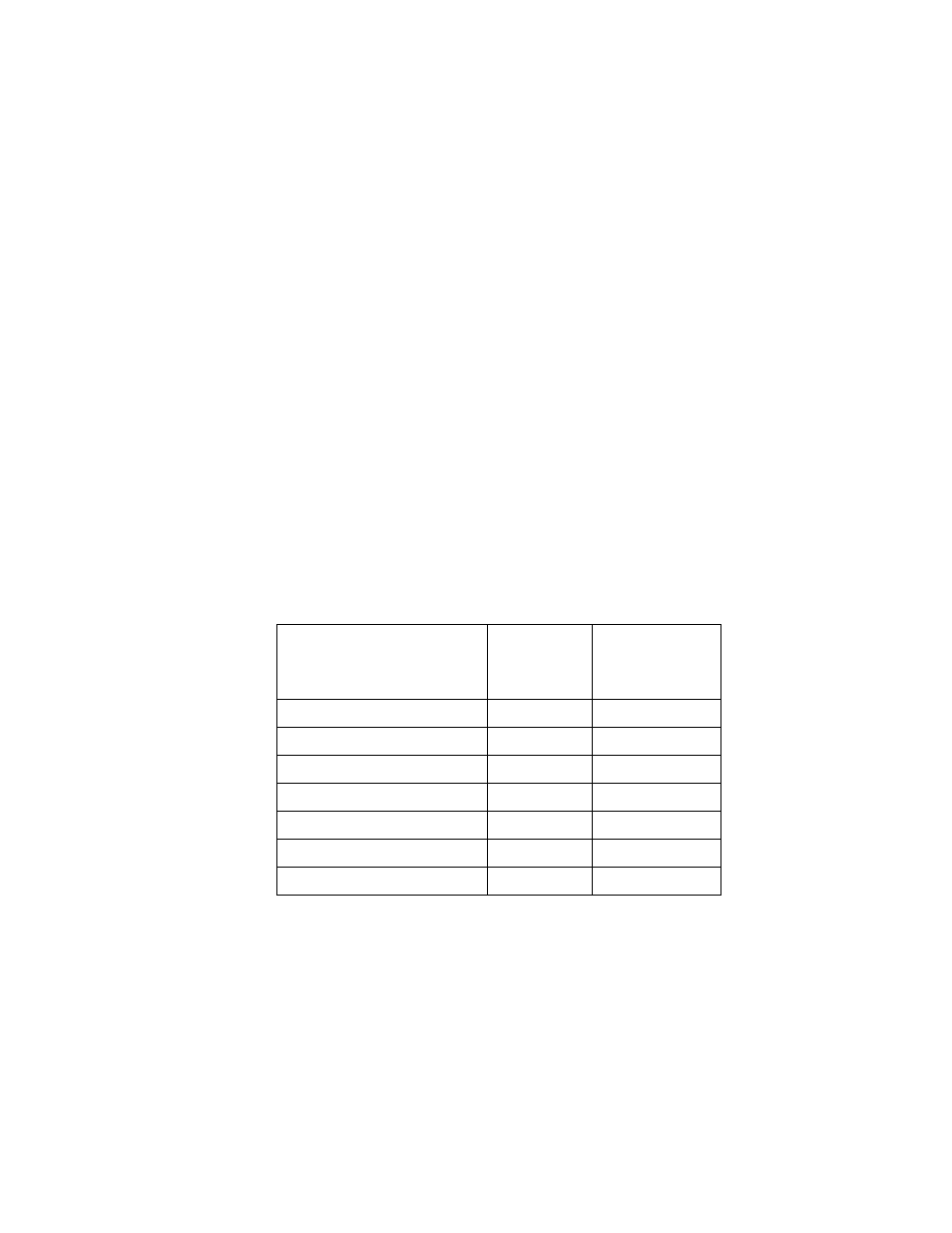

Table 3 lists the recommended installation distances from flow

disturbances. These recommendations apply to flow measurement

installations.

Feature

Upstream

pipe

diameters

Downstream

pipe

diameters

90 Degree Elbow

15

5

Double Elbow in plane

25

5

Double Elbow out of plane

40

5

Diffuser (expansion)

30

5

Reducer 15

5

Control Valve

40

10

Flange 2

2

Table 3

Recommended Distances From Flow Disturbances

7.4

Process Piping Considerations

The SONARtrac

TM

sensor head assembly mounts on the process

pipe. There is no need for breaking any process connections or for

shutting down the process. The sensor head must be installed in a

location that ensures a full pipe during operation.