11 hydraulic cylinders, 1 general cylinder removal instructions, 2 general cylinder disassembly – JLG G6-23A Service Manual User Manual

Page 86: Hydraulic cylinders, General cylinder removal instructions, General cylinder disassembly

Hydraulic System

8.16

G5-19A, G6-23A

8.11

HYDRAULIC CYLINDERS

8.11.1

General Cylinder Removal

Instructions

1. Park the machine on a firm, level surface, fully

retract the boom, lower the boom, place the

transmission control lever in (N) NEUTRAL, engage

the park brake and shut the engine OFF.

2. Chock the wheels.

3. Place an Do Not Operate Tag on both the ignition

key switch and the steering wheel, stating that the

machine should not be operated.

4. Open the engine cover. Allow the system fluids to

cool.

5. Label, disconnect and cap hydraulic hoses in

relation to the cylinder.

6. Attach a suitable sling to an appropriate lifting device

and to the cylinder. Make sure the device used can

actually support the cylinder.

7. Remove the lock bolt and/or any retaining clips

securing the cylinder pins. Remove the cylinder pins.

8. Remove the cylinder.

9. Wipe up any hydraulic fluid spillage in, on, near or

around the machine.

8.11.2

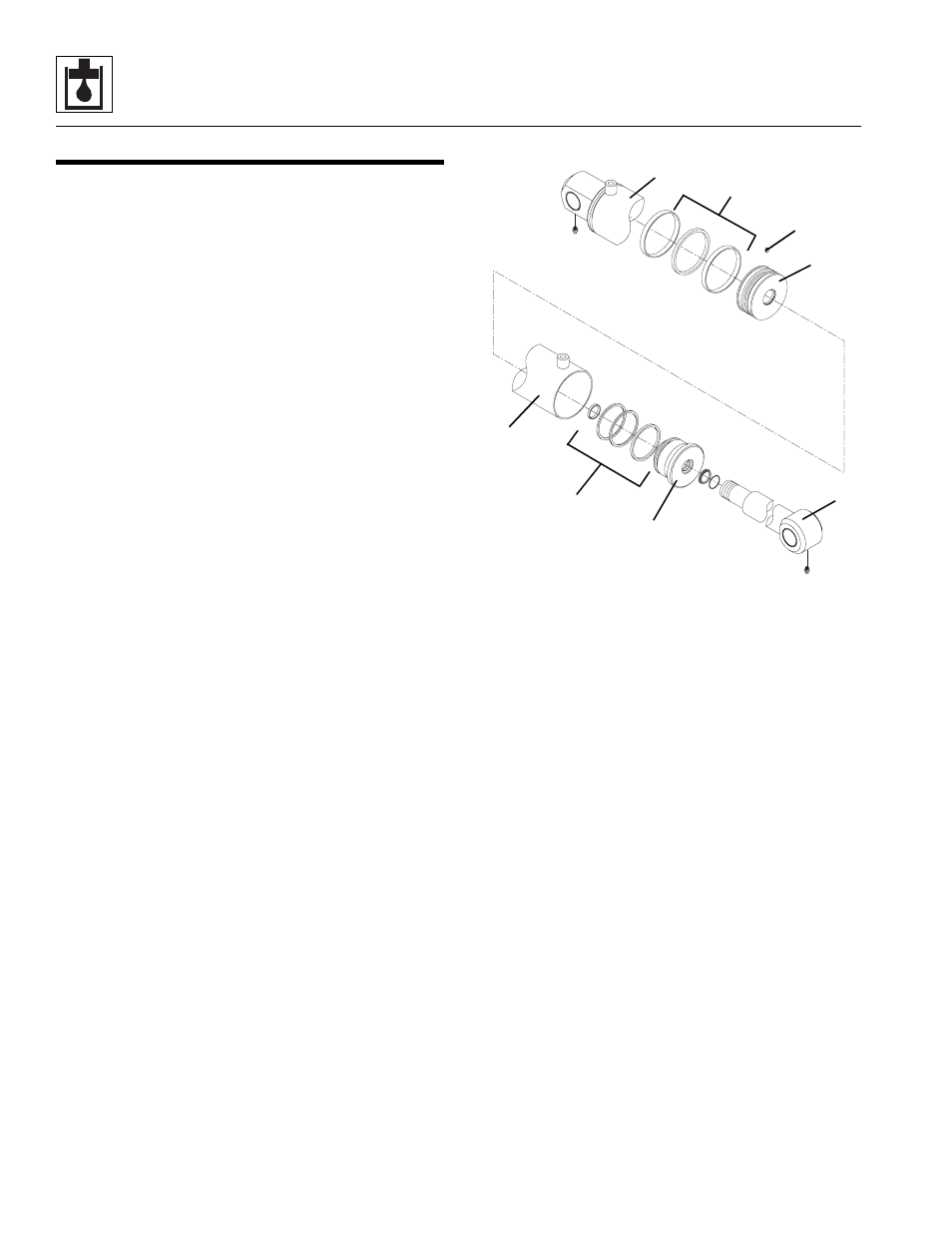

General Cylinder Disassembly

1. Clean the cylinder with a suitable cleaner before

disassembly. Remove all dirt, debris and grease

from the cylinder.

2. Clamp the barrel end of the cylinder in a soft-jawed

vise or other acceptable holding equipment if

possible.

IMPORTANT: Avoid using excessive force when

clamping the cylinder in a vise. Apply only enough force

to hold the cylinder securely. Excessive force can

damage the cylinder tube.

3. If applicable, remove the counterbalance valve from

the side of the cylinder barrel.

IMPORTANT: DO NOT tamper with or attempt to adjust

the counterbalance valve cartridge. If adjustment is

necessary, replace the counterbalance valve with a new

part.

4. Extend the rod (5) to allow access to the base of the

cylinder.

IMPORTANT: Protect the finish on the rod at all times.

Damage to the surface of the rod can cause seal failure.

5. Using a pin spanner wrench, unscrew the head

gland (6) from the barrel (1). A considerable amount

of force will be necessary to remove the head gland.

Carefully slide the head gland down along the rod

toward the rod eye end, away from the cylinder

barrel.

IMPORTANT: When sliding the rod and piston assembly

out of the tube, prevent the threaded end of the tube

from damaging the piston. Keep the rod centered within

the tube to help prevent binding.

6. Carefully pull the rod assembly along with the head

gland out of the cylinder barrel.

7. Fasten the rod end in a soft-jawed vise, and put a

padded support under and near the threaded end of

the rod to help prevent damage to the rod.

8. Remove the set screw (3) from the piston (4).

MAH0160

1

4

3

2

6

5

2

1