3 boom wear pad lubrication, 5 quick switch assembly, 1 connecting with a mechanical quick switch device – JLG G6-23A Service Manual User Manual

Page 29: Quick switch assembly, Boom wear pad lubrication, Connecting with a mechanical quick switch device

3.7

G5-19A, G6-23A

Boom

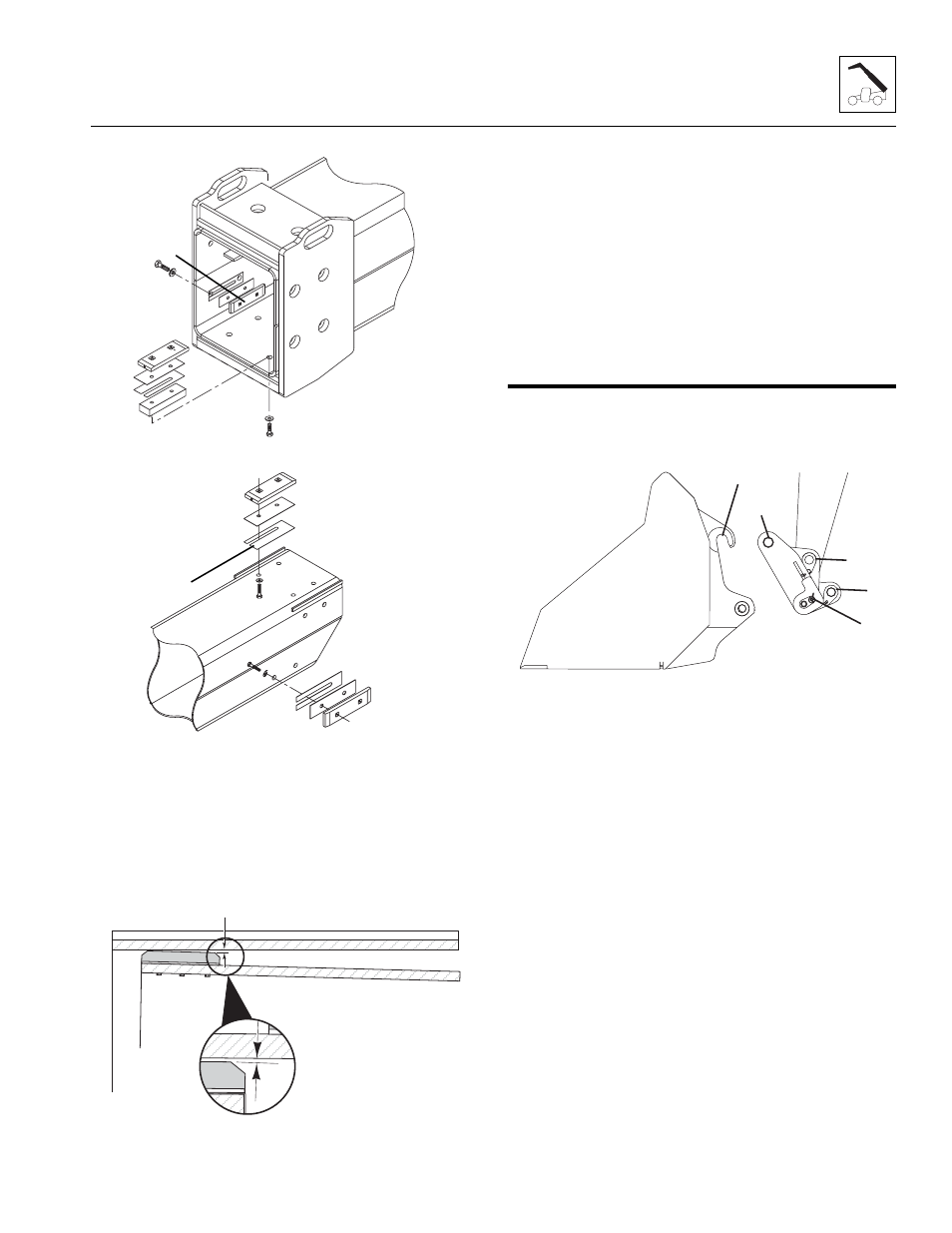

Use shims (6) under the wear pads as required to maintain

a maximum gap of 0.06 in (1,5 mm) (7) between the wear

pad on the front and sides of the boom. The gap at the

rear of the boom should be no more than 0.12 in (3 mm).

Shims are available in four thicknesses, 0.02 in (0,5mm),

0.04 in (1 mm), 0.06 in (1,5mm) and 0.08 in (2,0mm).

3.4.3

Boom Wear Pad Lubrication

After replacing any wear pad(s), or after prolonged

periods of inoperation, light lubrication of the boom wear

surfaces with a factory authorized grease is

recommended to keep the boom wear surfaces

lubricated properly. Light lubrication of the boom wear

surfaces is also recommended when the machine is

stored, to help prevent rusting.

Note: The first shim next to the pad needs to be the one

with holes, instead of the slots.

3.5

QUICK SWITCH ASSEMBLY

This machine is equipped with a quick switch system for

easy attachment changes.

3.5.1

Connecting with a Mechanical Quick

Switch Device

1. Retract quick switch device to provide clearance.

Check to be sure the retainer pin (8) is out.

2. Align attachment pin (10) with recess in

attachment (9). Raise boom slightly to engage

attachment pin in recess.

3. Engage quick switch device.

4. Shut off engine. Exit cab and insert lock pin and

secure with retainer pin.

5. If attachment is equipped, connect auxiliary

hydraulic hoses. See Section 3.5.3, “Connecting with

a Quick Switch to a Hydraulic Operated Attachment.”

MAH0300

5

MAH0870

6

MU4080

7

MAH1250

8

9

10

11

11