4 boom wear pads, 1 wear pad inspection, 2 boom wear pad replacement – JLG G6-23A Service Manual User Manual

Page 28: Boom wear pads, Wear pad inspection, Boom wear pad replacement

Boom

3.6

G5-19A, G6-23A

Install boom pivot pin (1) and lock bolt. Apply

Loctite

®

#242 and torque to 66 lb-ft (90 Nm).

6. With the sling still in place, install the compensating

cylinder, pin (2) and lock bolt. Apply Loctite

®

#242

and torque to 66 lb-ft (90 Nm).

7. With the sling still in place, install the rod end of the

lift/lower cylinder, pin and lock bolt. Apply Loctite

®

#242 and torque to 66 lb-ft (90 Nm).

Note: Raising the boom up or down with the sling may

be necessary so the boom, compensating and lift/lower

cylinder bores can be aligned for easier pin installation.

8. Uncap and reconnect the extend/retract cylinder

fittings and plugs from extend/retract cylinder hoses.

Attach each hose to the extend/retract cylinder

fittings and tighten until wrench-tight. Mark the fitting,

then tighten each hose firmly 1 to 1,5 flats.

9. Uncap and reconnect both the tilt and auxiliary

hoses. Attach both sets to their appropriate tubes

until wrench-tight. Mark the fitting, then tighten each

hose firmly 1 to 1,5 flats.

10. Start the engine and operate all boom functions

several times to bleed any air out of the hydraulic

system. Check for fluid leaks. Check the hydraulic

fluid level in the tank and add fluid as required.

11. Clean up all debris, hydraulic fluid, etc., in, on, near

and around the machine.

12. Close and secure the engine cover.

3.4

BOOM WEAR PADS

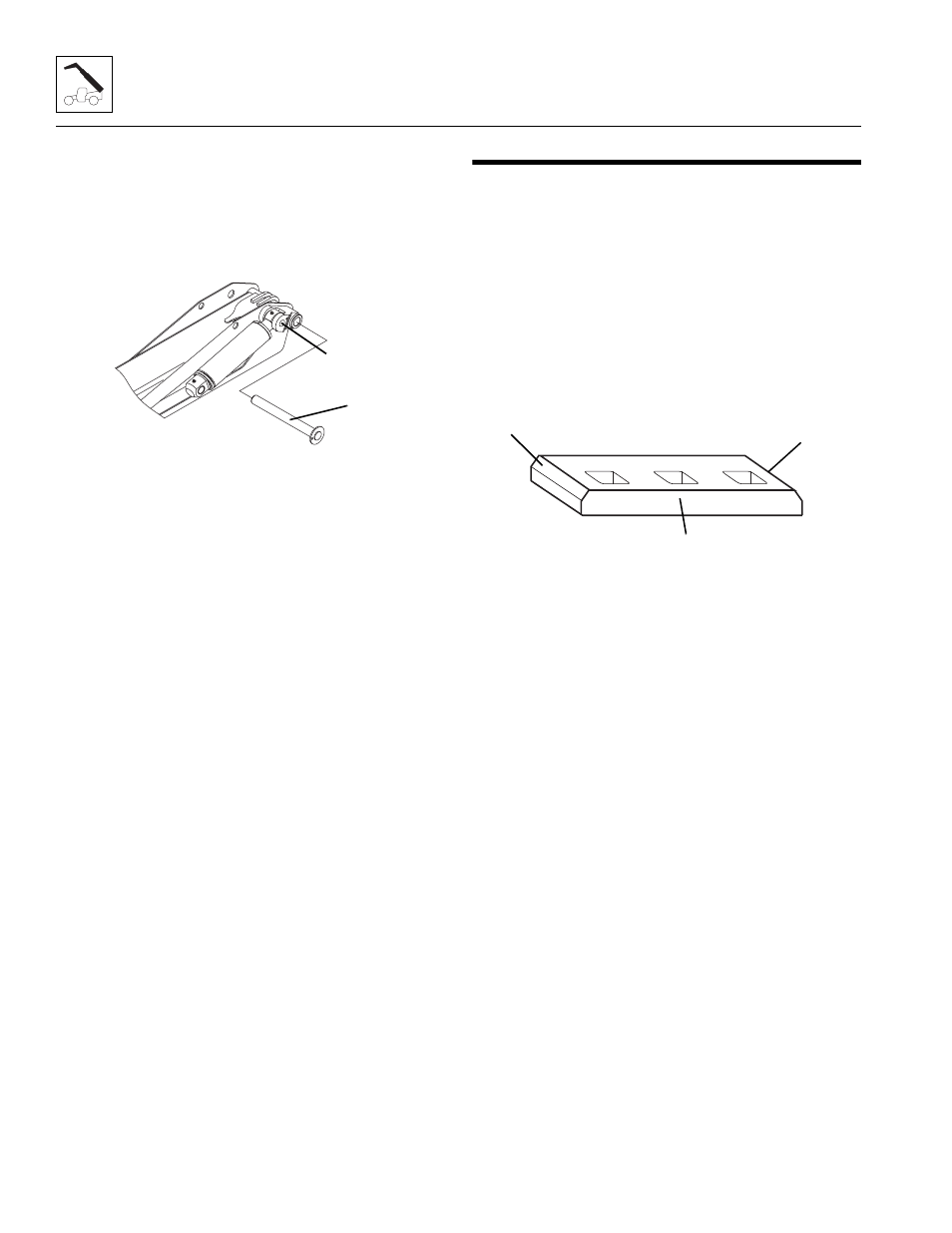

The wear pads on this machine are flat rectangular wear

pads with metal inserts.

On the G5-19A and G6-23A a total of 16 wear pads are

installed on the outer boom.

3.4.1

Wear Pad Inspection

Inspect all wear pads (3) for wear. If the angle

indicators (4) on the ends of the wear pads are visible, the

wear pads can be reused. If the pads show uneven wear

(front to back), they should be replaced. Replace pads as

a set if worn or damaged.

3.4.2

Boom Wear Pad Replacement

When replacing a wear pad on the boom, replace both

wear pads on that side of the boom; e.g.: replace top front

left and top front right wear pads at the same time.

Usually, shimming will remain the same when installing

new wear pads. All wear pads are secured to the boom

using different capscrews and washers. When installing

new wear pads, apply Loctite

®

#242 to all wear pad

mounting capscrews M10 and torque to 36 lb-ft (50 Nm).

Rear upper pads on G6-23A, apply Loctite

®

#242 to all

wear pad mounting capscrews M10 and torque to 66 lb-ft

(90 Nm). Grease the new pads and surrounding area.

The boom wear pads (5) are mounted on the inside of the

first boom section and the outside of the second boom

section.

MAH0140

2

1

MA2070

4

3

4