4 hourmeter, 5 coolant temperature sender, Hourmeter – JLG G6-23A Service Manual User Manual

Page 113: Coolant temperature sender

9.23

G5-19A, G6-23A

Electrical System

start the engine. Observe the fuel level indicator

needle on the operator’s instrument cluster.

3. Turn the ignition key switch to the OFF position. The

fuel level indicator needle should return to the

EMPTY position.

b. Fuel Level Circuit Tests

If the fuel level indicator is suspected of giving a false

reading, perform the following checks:

1. If the fuel level indicator needle does not move,

check the fuel tank for fuel.

2. Check for loose or defective wiring, faulty ground

connections or corrosion on the fuel tank sender and

wiring lead.

3. If the fuel level indicator needle does not move after

the ignition key switch is turned to the RUN position,

use a test lamp to determine whether current is

flowing from the ignition switch to the fuel level

sender.

4. If the fuel level indicator does not move and a faulty

or defective fuel level sender in the fuel tank has

been ruled out and in addition, wiring and

connectors have been checked and ruled out, the

fuel level indicator is defective and must be replaced.

5. Check that the ignition terminal has current and that

the fuse in the fuse panel is not blown.

6. Check for broken, shorted, frayed, disconnected or

damaged wiring between the fuel level indicator

wiring at the cab, fuse and relay panel, ignition key

switch and from the fuel level sender on the fuel tank

through the wiring in the cab.

7. Check the fuel level sender. The resistance of the

fuel level sender is 31 ohms for a full tank of fuel,

101 ohms for 1/2 tank and 255 ohms for an empty

tank. A defective fuel level sender in the fuel tank

may also prevent the fuel level indicator from

moving.

9.11.4

Hourmeter

The hourmeter is a non-repairable instrument that

records hours of machine engine operation in tenth of an

hour increments and is located in the instrument cluster.

The hourmeter is an analog device, similar to an

odometer, and will display 99,999.9 hours before

resetting to zero.

If trouble is suspected, time the hourmeter for six minutes

to verify that a tenth of an hour has been recorded.

The hourmeter is built into the instrument cluster and

cannot be repaired. If the hourmeter is suspect, replace

the instrument cluster.

9.11.5

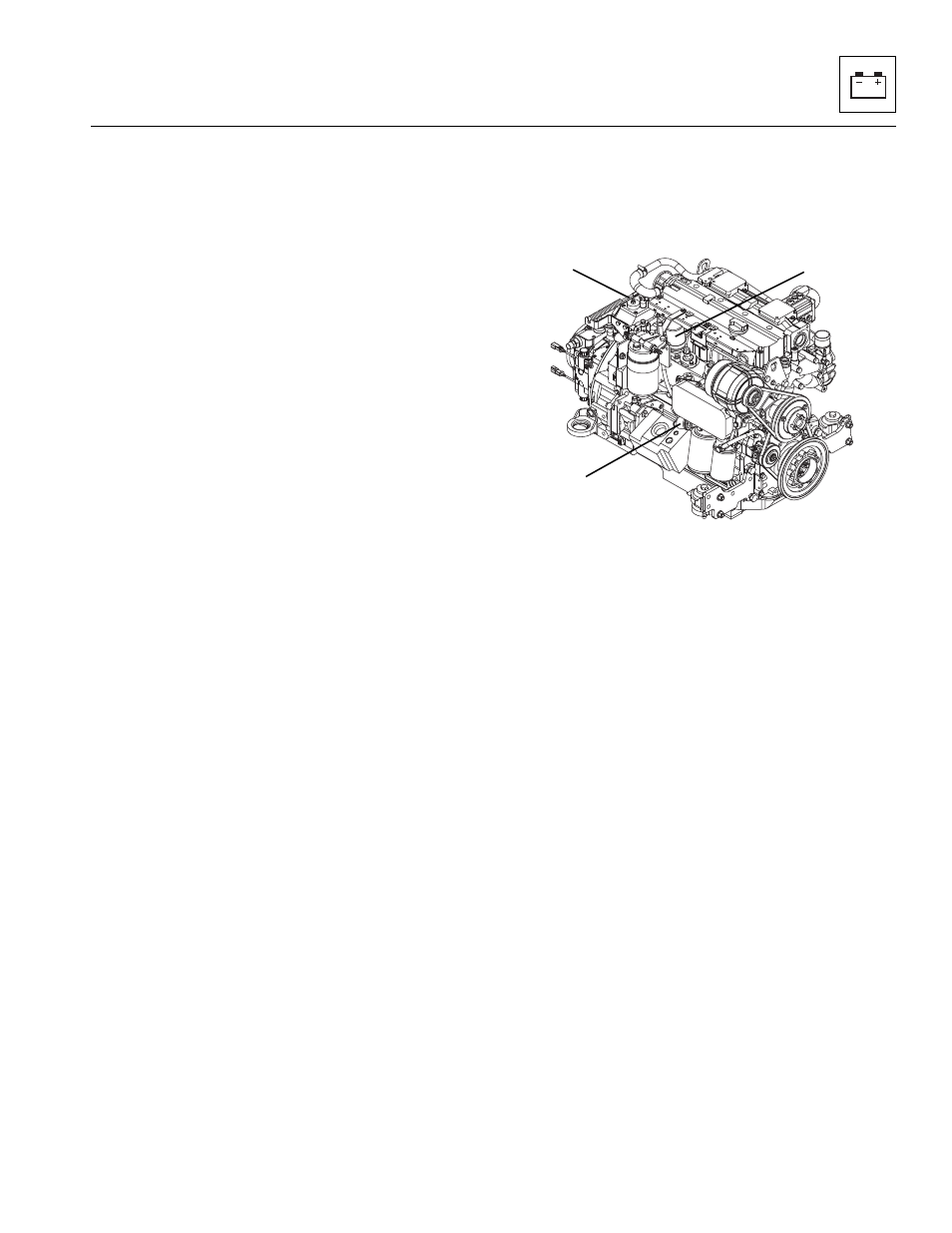

Coolant Temperature Sender

The coolant temperature sender (1) is located on the

back of the engine towards the rear of the machine.

a. Coolant Temperature Sender Removal

1. Open the engine cover. Allow the engine to cool.

2. Disconnect the battery negative (-) cable from the

battery negative (-) terminal.

3. Disconnect the wiring connector at the coolant

temperature sender lead.

4. The coolant temperature sender is threaded into the

engine block. Remove the sender.

b. Coolant Temperature Sender Inspection and

Replacement

Inspect the sender and the wiring harness connector

terminals for continuity. Replace a defective or faulty

sender with a new part.

c. Coolant Temperature Sender Installation and

Testing

1. Thread the coolant temperature sender into the

engine housing snugly, then connect the sender

connector to the wiring harness connector.

2. Connect the battery negative (-) cable to the battery

negative (-) terminal.

3. Check for proper fluid level.

4. Start the engine, allow it to reach operating

temperature and observe the operator’s instrument

cluster for warning indication. If the sender is not

defective, the problem could be elsewhere; possibly

MAH0620

1

2

3