5 engine electrical system, 6 fuel system, 1 diesel fuel – JLG G6-23A Service Manual User Manual

Page 65: Engine electrical system, Fuel system, Diesel fuel

7.5

G5-19A, G6-23A

Engine: Deutz BF 4M 2012

container. Dispose of properly if coolant needs to be

replaced. Close the radiator petcock.

10. Label, disconnect and cap all coolant hoses

attached to the radiator. Cap all fittings and openings

to keep dirt & debris from entering the cooling

system.

11. Label, disconnect and cap all hydraulic hoses

attached to the radiator. Cap all fittings and openings

to keep dirt & debris from entering the hydraulic

system.

12. Detach the fan safety shroud.

13. Remove the two brackets (1) at the front of the

radiator attached to the frame.

14. Remove the locknuts holding the isolator mounts at

the bottom of the machine.

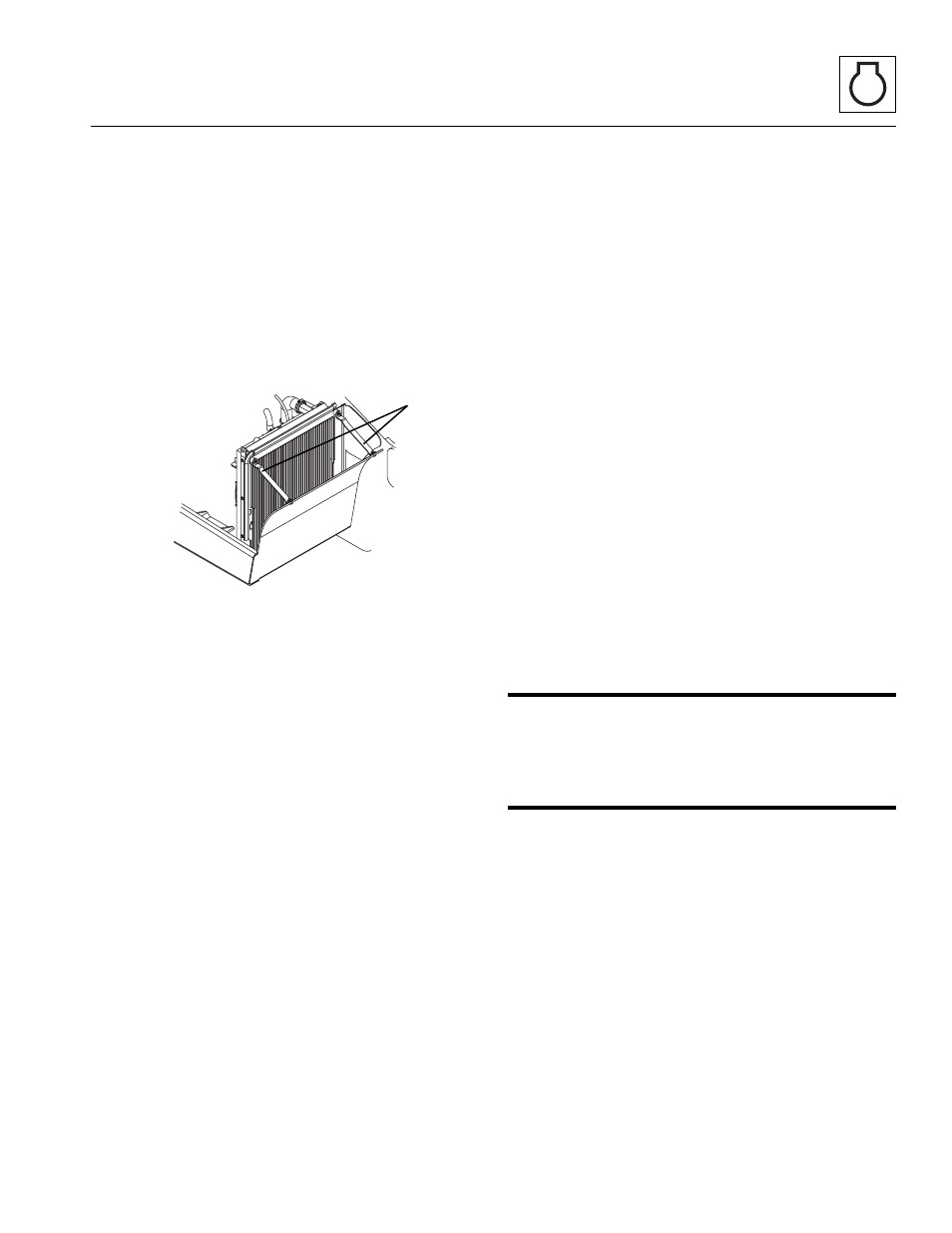

15. Connect a lifting strap to the radiator/oil cooler and

carefully lift the radiator/oil cooler out of the engine

bay.

b. Radiator/Oil Cooler Installation

1. Install the isolator mounts to the bottom of the

radiator. Insert radiator through the machine frame

and secure to the radiator mount plate with new

locknuts.

2. Be sure the engine fan has clearance in regard to

the radiator. Install the two brackets (1) on the front

of the radiator to the frame.

3. Attach the fan safety shroud.

4. Uncap and reconnect the previously labeled

hydraulic hoses to the appropriate locations.

5. Uncap and reconnect all previously labeled coolant

hoses to the appropriate locations.

6. Fill the coolant overflow bottle with a 50/50 mixture

of ethylene glycol and water.

7. Connect the battery negative (-) cable to the battery

negative (-) terminal.

8. Run the engine to operating temperature. Visually

check for leaks with the engine running. Check the

coolant level in the overflow bottle and fill, or drain,

as necessary. Check the hydraulic fluid level in the

tank and add fluid as required.

9. Attach the belly pan of the engine compartment.

10. Close and secure the engine cover.

7.5

ENGINE ELECTRICAL SYSTEM

The engine electrical system, including the starter,

alternator and primary wiring, is described in Section 9,

“Electrical System.”

7.6

FUEL SYSTEM

7.6.1

Diesel Fuel

Fuel represents a major portion of machine operating

costs and therefore must be used efficiently. ALWAYS

use a premium brand of high-quality, clean diesel fuel.

Low cost, inferior fuel can lead to poor performance and

expensive engine repair.

Note: Use only diesel fuel designed for diesel engines.

Some heating fuels contain harmful chemicals that can

seriously affect engine efficiency and performance.

IMPORTANT: Due to the precise tolerances of diesel

injection systems, keep the fuel clean, and free of dirt

and water. Dirt and water in the fuel system can cause

severe damage to both the injection pump and the

injection nozzles. Use ASTM #2 diesel fuel with a

minimum Cetane rating of 40. #2 diesel fuel gives the

MAH0290

1