2 lowering procedure, Warning – JLG G12-55A Service Manual User Manual

Page 66

Boom

3-30

G10-55A, G12-55A

Hoses:

• Two Hydraulic Hoses - Approximately 10 ft

(3,0 m) each, with a minimum I.D. of

0.375 in (9,5 mm) and a minimum rating of

4000 psi (275,8 bar).

G10-55A or G12-55A - Fittings:

• Two -12 ORFS Caps

• Two -12 ORFS Plugs

Adaptors:

• Two -12 ORFS 90° Adaptors

Note: The adaptor size may vary depending on the

hose ends of the auxiliary hydraulic power supply.

3.13.2

Lowering Procedure

a. Retract the boom as follows:

1. If equipped with Personal Work Platform, rescue

occupants prior to performing procedure.

2. Properly support the boom before attempting to

proceed with the emergency boom lowering

procedure.

3. Place a Do Not Operate Tag on both the ignition key

switch and steering wheel.

4. Properly support the boom as required.

5. Place a suitable receptacle under the main control

valve.

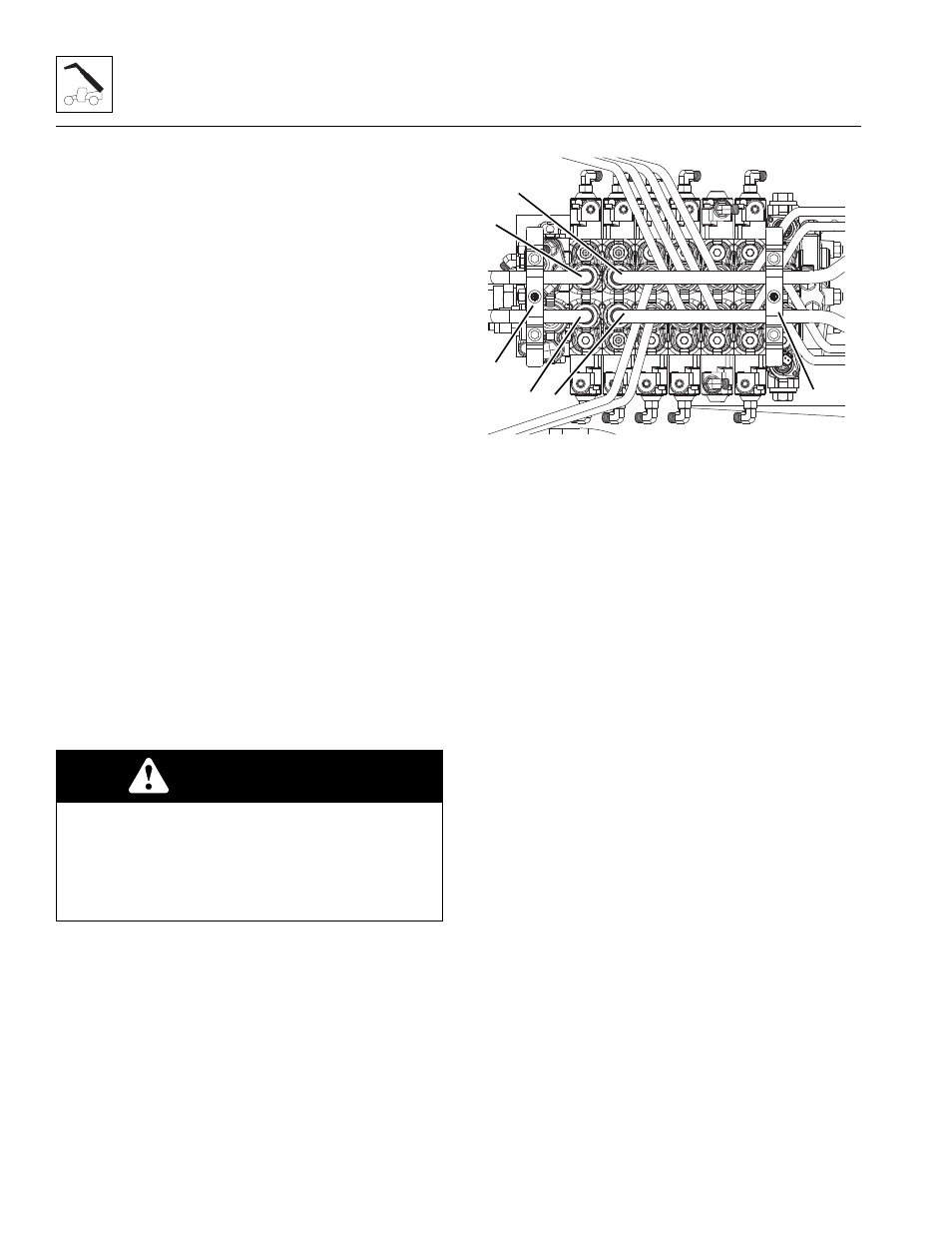

6. Remove the plastic cover from the top of the main

control valve.

7. Remove the brackets (5) that is attached to the steel

tubes supporting the plastic cover.

8. Loosen and remove any clamps securing the

extend/retract cylinder (1 & 2) and lift/lower cylinder

tubes (3 & 4) together and to the frame.

9. Disconnect the extend/retract cylinder tubes (1 & 2)

from the main control valve. Install plugs in tubes to

prevent fluid loss. Cap all fittings and openings to

keep dirt and debris from entering the hydraulic

system.

10. Using the hoses and fittings specified, connect the

hoses between the auxiliary hydraulic power supply

and the tubes removed from the main control valve

extend/retract section of the affected machine.

Retract tube (1) is the supply and extend tube (2) is

the return. Connect the hoses in the proper order to

ensure that the cylinder is retracted, not extended.

11. Remove the previously installed the boom support.

12. Use the auxiliary power supply to slowly retract the

extend/retract cylinder.

13. Properly support the boom as required.

14. Loosen and remove the jumper hoses, caps, plugs

and reconnect the extend/retract cylinder tubes.

Torque as required.

b. Lower the boom as follows:

1. Place a suitable receptacle under the main control

valve.

2. Disconnect the lift/lower cylinder tubes (3 & 4) from

the main control valve. Install plugs in tubes to

prevent fluid loss. Cap all fittings and openings to

keep dirt and debris from entering the hydraulic

system.

WARNING

Loss of hydraulic oil is limited to the amount trapped

within each tube/hose. Slowly loosen each hydraulic

tube fitting to release any possible hydraulic oil

pressure that may be trapped between the main

control valve and the counterbalance valve of the

extend/retract cylinder or the lift/lower cylinder.

MAL2690

1

4

G10-55A/G12-55A

5

5

2

3