4 boom hose take-up adjustment, 5 boom hose adjustment, Boom hose adjustment – JLG G12-55A Service Manual User Manual

Page 56

Boom

3-20

G10-55A, G12-55A

11. Uncap and reconnect the previously labeled tilt and

auxiliary hydraulic hoses to the proper fittings at the

front of the fourth boom section.

12. If equipped, reconnect any electrical connections at

the front and rear of the boom assembly.

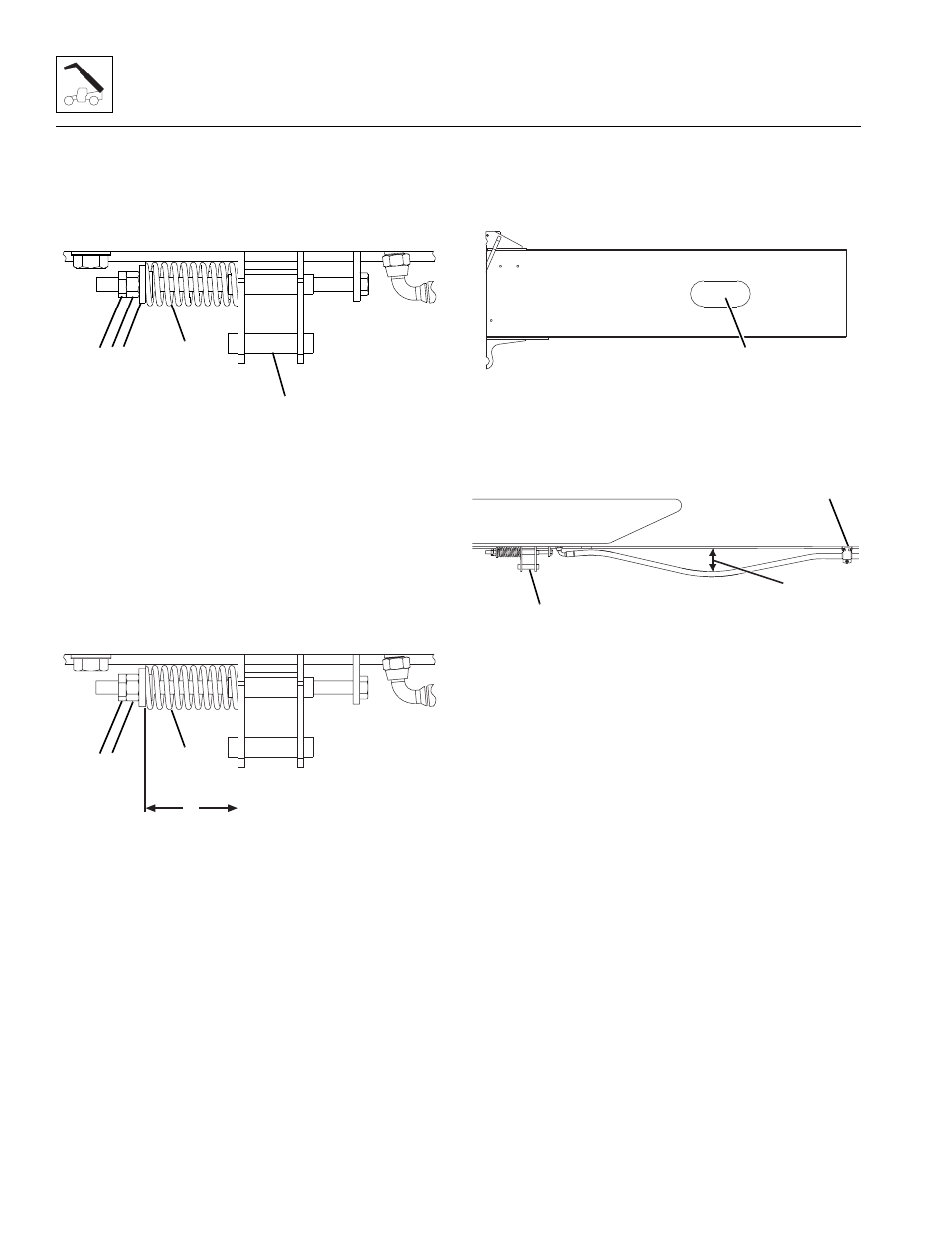

13. Install the boom hose take-up compression spring

(4) on each hose take-up bracket (5) at the bottom of

the first boom section. Install the washer (6),

adjusting nut (7) and jam nut (8).

14. Properly connect the battery.

15. Remove the Do Not Operate Tags from both the

ignition key switch and the steering wheel. Refer to

Section 3.7.4, “Boom Hose Take-up Adjustment,” for

detailed adjustment procedure.

3.7.4

Boom Hose Take-up Adjustment

1. Tighten the adjusting nut (7) to compress the hose

take-up compression spring (4) to measure 2.875-

3.187 in (73-81 mm)(9). Refer to Section 3.7.5,

“Boom Hose Adjustment,” if required.

2. Torque the jam nut (8) against the adjusting nut (7)

to 100 ft-lb (135,5 Nm).

3.7.5

Boom Hose Adjustment

1. Park the machine on a hard, level surface, level the

machine, fully extend the boom, lower the boom

head to the ground, place the transmission control

lever in (N) NEUTRAL, engage the park brake and

shut the engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel.

3. Verify any trapped hydraulic pressure in the auxiliary

circuit and the tilt circuit is relieved.

4. Open the engine cover. Allow the system fluids to

cool.

5. Verify the auxiliary hoses and/or tilt hoses are NOT

touching the bottom of the second boom section by

viewing the auxiliary hoses and/or tilt hoses through

the access hole (10) in each side of the second

boom section.

6. Verify that 4 in (101,6 mm) of slack (11) is present

between the hose take-up bracket (5) and the first

hose clamp (12).

7. Verify the hose take-up bracket (5) is not bent and is

at an 85° angle to the hose.

Note: Replace both auxiliary hoses and/or tilt hoses if

the hoses are touching the bottom of the second boom

section AND 4 in (101,6 mm) of slack is present between

the hose take-up bracket and the first hose clamp.

8. Refer to Section 3.7.4, “Boom Hose Take-up

Adjustment,” for boom hose take-up adjustment.

9. Measure the slack (11) at the lowest point between

the hose take-up bracket (5) and the first hose clamp

(12). The 4 in (101,6 mm) measurement is from the

bottom of the first boom section to the top of the

hose.

10. If necessary, loosen the hose clamp (12), pull the

auxiliary hoses and/or the tilt hoses, tighten the hose

clamp for additional clearance.

11. Replace the auxiliary hoses and/or the tilt hoses if

the proper slack, 4 in (101,6 mm)(11) cannot be

achieved.

12. Start the machine, raise the boom to level, cycle the

extend/retract cylinder, fully extend the boom.

MY9310

4

5

8 7 6

MY2691

9

8 7

4

MY4480

10

MY4470

12

5

11