Wear tolerance, Wear tolerance -50, Swing bearing feeler gauge check -50 – JLG E300 Service Manual User Manual

Page 84: Swing bearing tolerance measuring point -50

SECTION 3 - CHASSIS & TURNTABLE

3-50

– JLG Lift –

3121253

c. Lower the main boom to horizontal and fully

extend the boom.

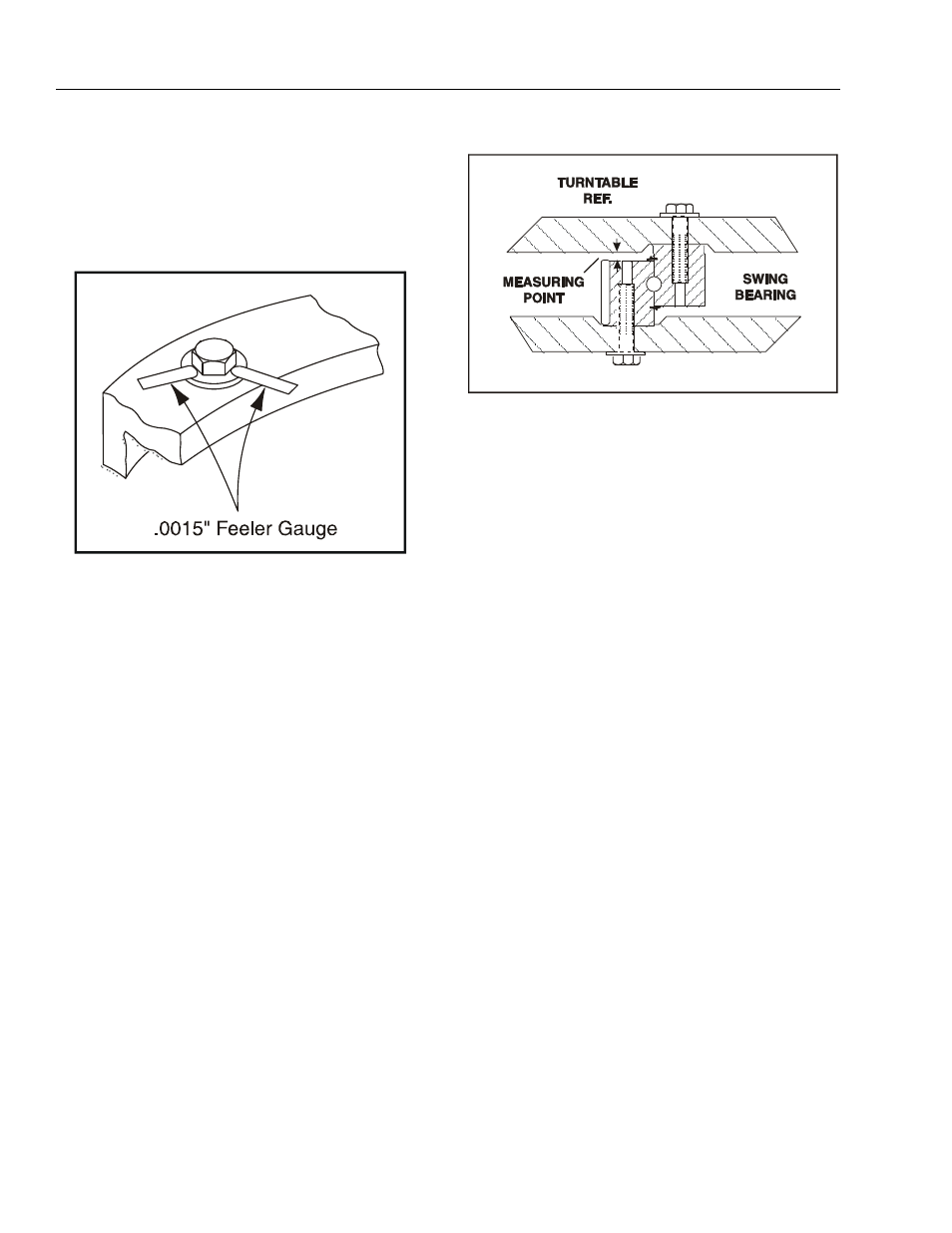

d. At the position indicated on Figure 3-24., Swing

Bearing Tolerance Boom Placement try and

insert the.0015” feeler gauge between the bolt

head and hardened washer at the arrow indi-

cated position.

Wear Tolerance

1. With the boom positioned over the side of the

machine, the Upper Boom horizontal with telescope

fully extended and Tower Boom raised half way

(approx 37°)See Figure 3-25., Swing Bearing Toler-

ance Boom Placement, using a magnetic base dial

indicator, measure and record the distance between

the swing bearing and turntable. (See Figure 3-23.,

Swing Bearing Tolerance Measuring Point)

2. At the same point, with the boom positioned over

the side of the machine, the Upper Boom fully

extended and fully retracted, the platform rotated

max. to the side, and the Tower Boom fully elevated,

(See Figure 3-24., Swing Bearing Tolerance Boom

Placement) using a magnetic base dial indicator,

measure and record the distance between the swing

bearing and turntable (Figure 3-23., Swing Bearing

Tolerance Measuring Point).

3. If a difference greater than 0.057 in. (1.40 mm) is

determined, the swing bearing should be replaced.

4. If a difference less than 0.057 in. (1.40 mm) is deter-

mined, and any of the following conditions exist, the

bearing should be removed.

a. Metal particles in the grease.

b. Increased drive power.

c. Noise.

d. Rough rotation.

5. If bearing inspection shows no defects, reassemble

bearing and return to service.

Figure 3-22. Swing Bearing Feeler Gauge Check

Figure 3-23. Swing Bearing Tolerance Measuring Point