Cleaning and inspection, Assembly, Cleaning and inspection -12 assembly -12 – JLG E300 Service Manual User Manual

Page 154

SECTION 5 - HYDRAULICS

5-12

– JLG Lift –

3121253

4. Withdraw the O-ring and back up ring carefully as

not to damage the seals.

5. It is impossible to disassemble the bushing because

it is pressed on. Remove it by using a press.

PISTON SEAL DISASSEMBLY

1. The piston seal is used in pairs and the ring at the

outer diameter is easily removed by hand. Remove

the inner rubber ring carefully with the disassembly

tool so as not to cause damage to a processed

good.

2. Carefully remove the o-ring and back up ring with

the disassembly tool as not to cause damage to the

seals.

Cleaning and Inspection

1. Clean all parts thoroughly in an approved cleaning

solvent.

2. Inspect the rod threads for the additional damage. If

necessary, dress rod threads.

3. Inspect the inside of the cylinder barrel for any dam-

age. Inspect the inside diameter for tapering or oval-

ity.

4. Inspect the barrel threads for the damage and dress

threads as necessary.

5. Inspect the piston surface for the damage. Replace

the piston if necessary.

6. Inspect the piston threads for damage.

7. Inspect the seal and o-ring grooves for burrs and

sharp edges. Dress the surface as necessary.

8. Inspect the cylinder head inside diameter for dam-

age, ovality and tapering. Replace as necessary.

9. Inspect the head threads for damage. Dress the

threads as necessary.

10. Inspect the gland seal and o-ring grooves for the

burr and sharp edge. Dress the surface as neces-

sary.

11. Inspect the cylinder head outside diameter for dam-

age, ovality and tapering. If necessary, replace it.

12. Inspect rod and tube bearings for signs of excessive

wear or damage.

Assembly

NOTE: Prior to cylinder assembly, ensure that the proper

cylinder seal kit is used. Refer to the JLG parts man-

ual.

GLAND, PISTON SEAL ASSEMBLY

1. Install the new rod seal into the applicable cylinder

gland grooves by hand.

2. Use a soft mallet to tap a new wiper seal into the

applicable cylinder head gland groove. Install a new

wear ring into the applicable cylinder head gland

groove.

3. Place the o-ring and back up seal in the outside

grooves of the cylinder gland.

4. Install a washer ring onto the rod and carefully install

the gland on the rod ensuring that the wiper and rod

seals are not damaged or dislodged. Push the head

gland along the rod to the rod end, as applicable.

5. Carefully slide the piston spacer on the rod.

NOTE: The main boom telescope cylinder piston has an o-

ring installed inside the spacer.

6. If applicable, correctly place the o-ring in the inner

piston diameter groove. The back up ring side fac-

ing the o-ring is grooved.

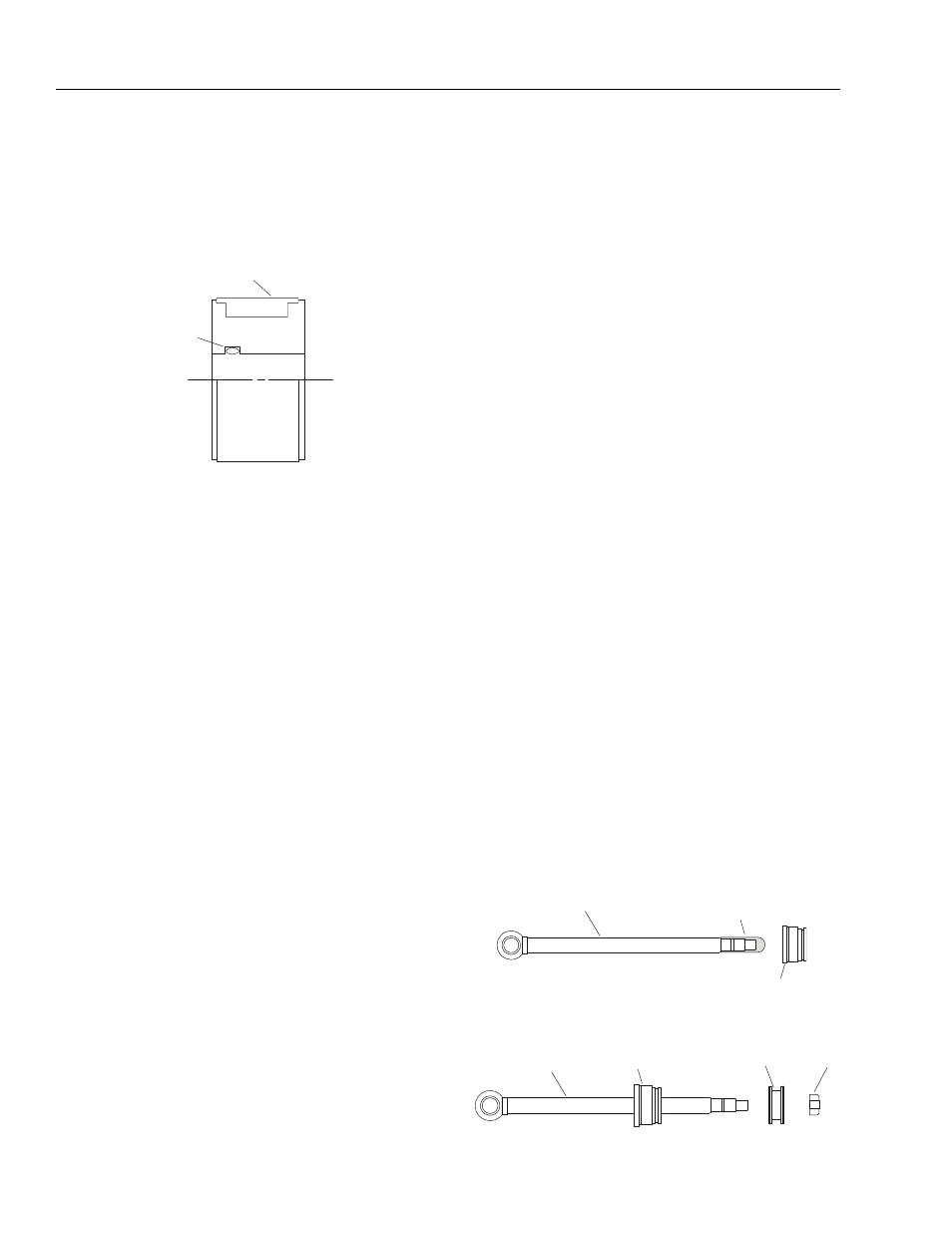

GLAND, PISTON, PISTON NUT ASSEMBLY

1. Clamp the rod assembly

2. Use a guide jig so as not to cause damage to the

inner seal of the gland and assemble it.

3. Assemble the piston onto the rod assembly

PISTON SEAL

O-RING

ROD ASSEMBLY

GLAND

GUIDE JIG

ROD ASSEMBLY

GLAND

PISTON

NUT