JLG E300 Service Manual User Manual

Page 76

SECTION 3 - CHASSIS & TURNTABLE

3-42

– JLG Lift –

3121253

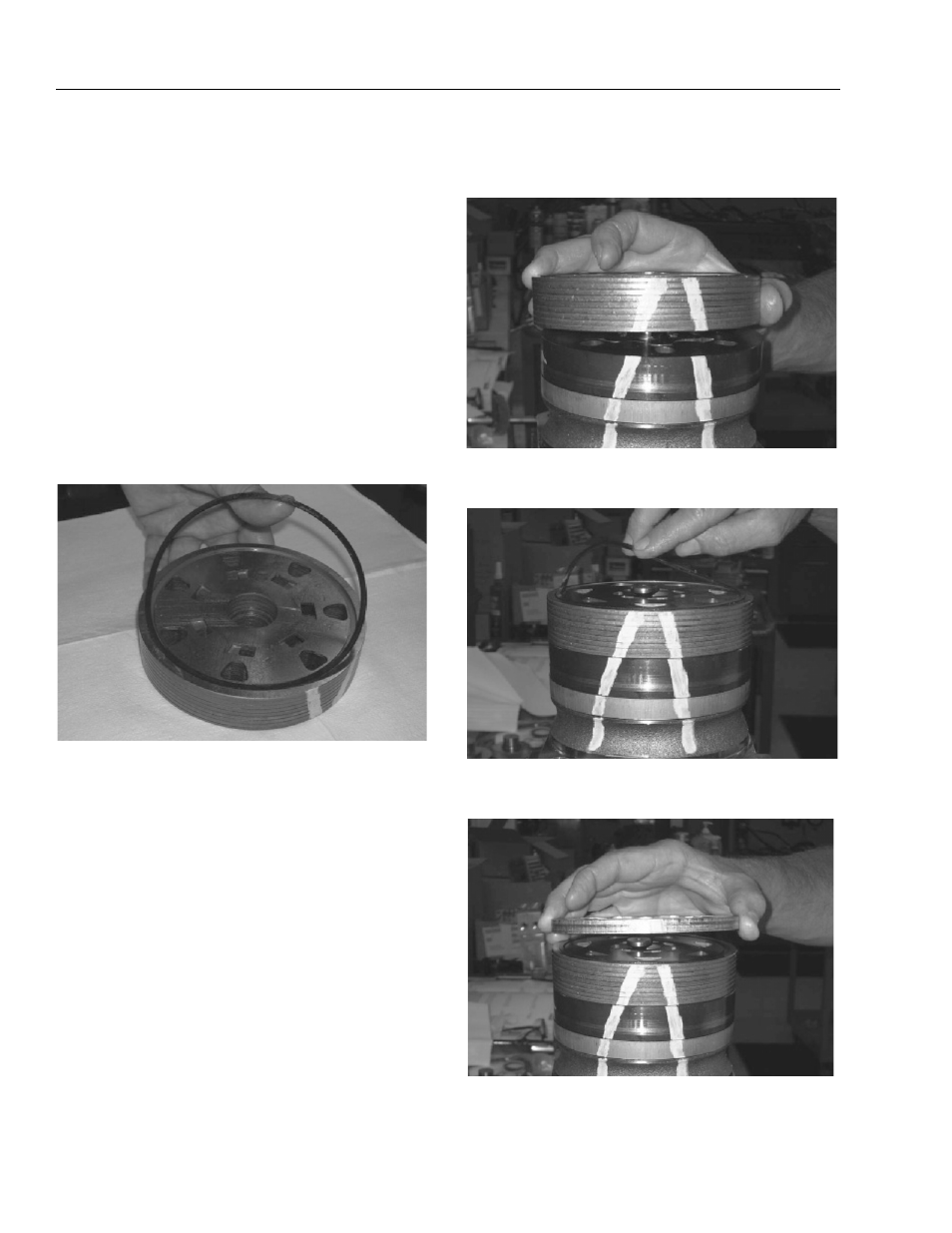

NOTE: It may be necessary to turn one alignment stud out

of the housing (18) temporarily to assemble rotor set

(8) or manifold (7) over the drive link.

NOTE: If necessary, go to the appropriate, "Rotor Set Com-

ponent Assembly Procedure."

NOTE: The rotor set rotor counterbore side must be down

against wear plate for drive link clearance and to

maintain the original rotor-drive link spline contact. A

rotor set without a counterbore and that was not

etched before disassembly can be reinstalled using

the drive link spline pattern on the rotor splines if

apparent, to determine which side was down. The

rotor set seal ring groove faces toward the wear plate

(9).

14. Apply clean grease to a new seal ring (4) and

assemble it in the seal ring groove in the rotor set

contact side of manifold (7).

NOTE: The manifold (7) is made up of several plates

bonded together permanently to form an integral

component. The manifold surface that must contact

the rotor set has it’s series of irregular shaped cavi-

ties on the largest circumference or circle around the

inside diameter. The polished impression left on the

manifold by the rotor set is another indication of

which surface must contact the rotor set.

15. Assemble the manifold (7) over the alignment studs

and drive link (10) and onto the rotor set. Be sure the

correct manifold surface is against the rotor set.

16. Apply grease to a new seal ring (4) and insert it in

the seal ring groove exposed on the manifold.

17. Assemble the commutator ring (6) over alignment

studs onto the manifold.

18. Assemble a new seal ring (3) flat side up, into com-

mutator (5) and assemble commutator over the end