JLG E300 Service Manual User Manual

Page 194

SECTION 6 - JLG CONTROL SYSTEM

6-26

– JLG Lift –

3121253

776

77

STALLED PUMP MOTOR OR POWER WIRING ERROR

The power module pump MOSFET protection circuit is active,

This is due to a massive current drain and could be a stalled pump

motor or a power wiring error

777

77

OPEN CIRCUIT PUMP MOTOR WIRING

Pump point A is collapsing when the pump MOSFETs are pulsed,

this maybe due to an OPEN circuit pump motor or a power wiring

error

7734

77

TRACTION A HIGH - CHECK POWER CIRCUITS

Traction point A is near battery supply when neither direction con-

tactor is energized and the traction MOSFETs are OFF, this maybe

due to a welded direction contactor or a power wiring error

7735

77

TRACTION A LOW - CHECK POWER CIRCUITS

Traction point A is near ZERO volts when neither direction contac-

tor is energized and the traction MOSFETs are OFF, this maybe due

to a power wiring error

7736

77

TRACTION MOTOR OVERLOADED

The traction motor has been operating in current limit at a low per-

centage on for a long time greater than 10 seconds

7737

77

PUMP MOTOR OVERLOADED

The pump motor has been operating in current limit at a low per-

centage on for a long time greater than 10 seconds

7738

77

PUMP A LOW - CHECK POWER CIRCUITS

Pump point A is near ZERO volts when the pump MOSFETs are

OFF, this maybe due to a power wiring error

7739

77

B+ AND A CROSSED - CHECK POWER CIRCUITS

startup test detected B+ is connected to point A and point A is

connected to B+

7740

77

TRACTION CURRENT AT ZERO - CHECK SHUNT WIRING

Traction current is at ZERO, this maybe due to an open circuit

between the current measurement shunt and the power module

826

82

RUNNING AT CREEP - PLATFORM OVERLOADED

All functions at creep, the Load Sensing System indicates the

Platform is overloaded AND is configured to warn only while the

Platform is overloaded.

827

82

DRIVE & BOOM PREVENTED - PLATFORM OVERLOADED

Driving and boom functions are not possible while the Load Sens-

ing System indicates the Platform is overloaded AND is config-

ured to prevent drive and boom functions while the Platform is

overloaded.

99125

99

POWER MODULE FAILURE - HWFS CODE 2

Hardware failsafe tests did not com plete because traction point A

is not safe, or the hardware failsafe is permanently tripped

99126

99

POWER MODULE FAILURE - HWFS CODE 3

Hardware failsafe tests did not complete because a contactor

was energized when all should be turned off

99127

99

POWER MODULE FAILURE - HWFS CODE 4

Hardware failsafe tests did not complete because the hardware

failsafe tripped immediately when the traction MOSFETs were

turned ON

99128

99

POWER MODULE FAILURE - HWFS CODE 10

Hardware failsafe tests failed because the hardware failsafe did

not trip within the allowed test time

99129

99

POWER MODULE FAILURE - HWFS CODE 11

Hardware failsafe tests failed because the hardware failsafe

tripped too slowly

99130

99

POWER MODULE FAILURE - HWFS CODE 12

Hardware failsafe tests failed because the hardware failsafe

tripped too Quickly

99131

99

POWER MODULE FAILURE - HWFS CODE 13

Hardware failsafe tests failed because the hardware failsafe

remained tripped when the traction MOSFETs were turned OFF

99132

99

POWER MODULE FAILURE - HWFS CODE 14

Hardware failsafe tests failed because the hardware failsafe the

line contactor could not be energized when the hardware failsafe

was tripped

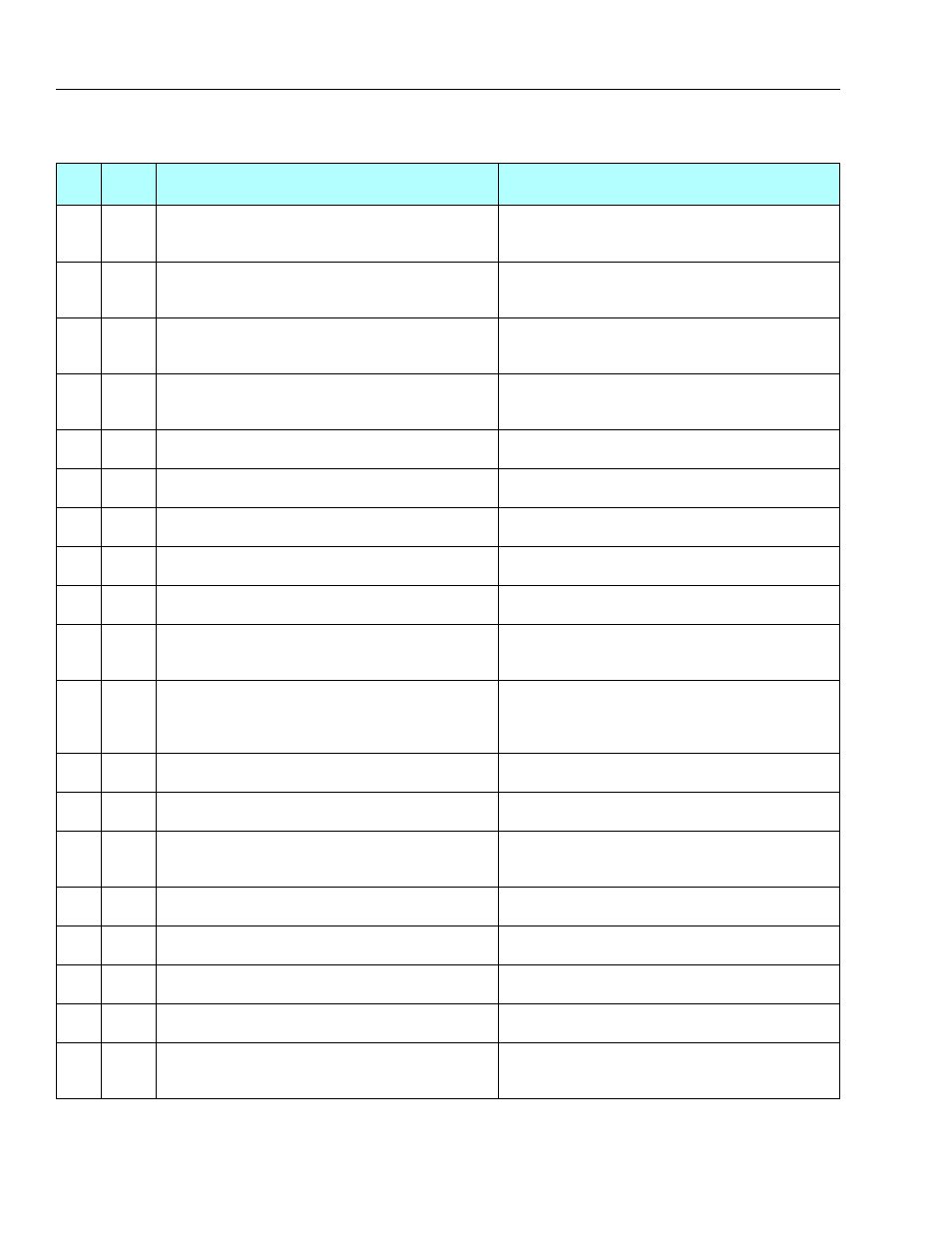

Table 6-4. E300 Diagnostic Fault Codes

DTC

Flash

Code

Fault Message

Description