Danger – Brother HE-800A User Manual

Page 62

HE-800A

5. OPERATION

54

ዑ-ውዏ. Adding patterns created using the programming software for

electronic pattern sewer

You can use the programming software for electronic pattern sewer to create your own sewing patterns.

Up to nine of the patterns which you create in this way can be programmed into a P-ROM.

DANGER

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall

outlet before opening the face plate of the control box. Touching areas where high voltages are present can

result in severe injury.

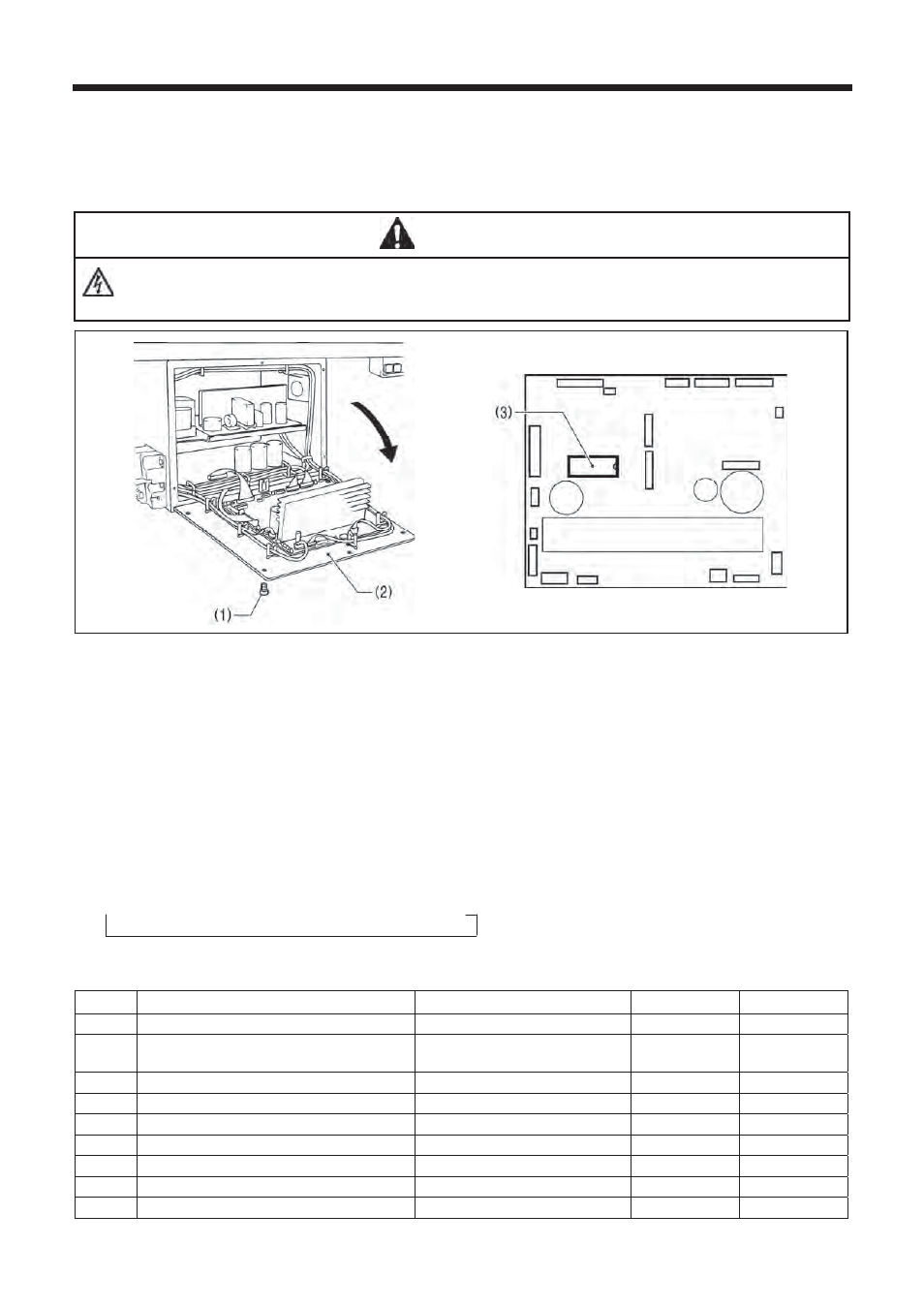

1. Remove the six screws (1), and then open the cover (main P.C. board mounting plate (2)).

Note: When opening the cover, hold it securely so that it does not fall down.

2. Remove the P-ROM (3) from the main P.C. board.

3. Create the pattern(s) using the programming software for electronic pattern sewer. Refer to the Operating

Instructions for the programming software for electronic pattern sewer for details on how to create patterns.

4. Add the pattern(s) created to the P-ROM (3).

5. Install the P-ROM (3) to the main P.C. board so that it faces as shown in the illustration.

Note: If attached in reverse way, P-ROM may be damaged.

6. Close the cover (main P.C. board mounting plate (2)), and tighten the six screws (1).

The program numbers for patterns which have been created using the programming software for electronic pattern

sewer range from P1 to P9. However, program numbers which have not yet been assigned to a program will not

appear on the program number LED.

ψ 1ψ 2ψ 3ψ……ψ 90ψ P1ψ P2ψ……ψ P9

You can check and change the following parameters for patterns which have been created using the programming

software for electronic pattern sewer.

No.

Setting items

Setting range

Unit

Default

00

Sewing speed (zigzag part)

1,000 - 4,000 sti/min

100

3,600

02

Length of knife

Value is for checking purposes

and cannot be changed.

- -

08

Knife X position alignment

-0.5 - 0.5mm

0.1

0.0

09

Knife Y position alignment

-0.8 - 0.8mm

0.1

0.0

16

Running speed (Straight bar tack)

1,000 - 3,000 sti/min

100

2,000

48

Underlay speed

1,000 - 3,000 sti/min

100

2,000

60

Slow speed

500 - 1,500 sti/min

100

800

61

Rear tack speed

500 - 4,000 sti/min

100

4,000

62

Front tack speed

500 - 4,000 sti/min

100

4,000

3944Q

3945Q