Brother HE-800A User Manual

Page 105

HE-800A

16. TROUBLESHOOTING

97

ውዒ-ዕ. Uneven seams (7) …… Loose thread end at end backtack

Cause Check

Remedy

Page

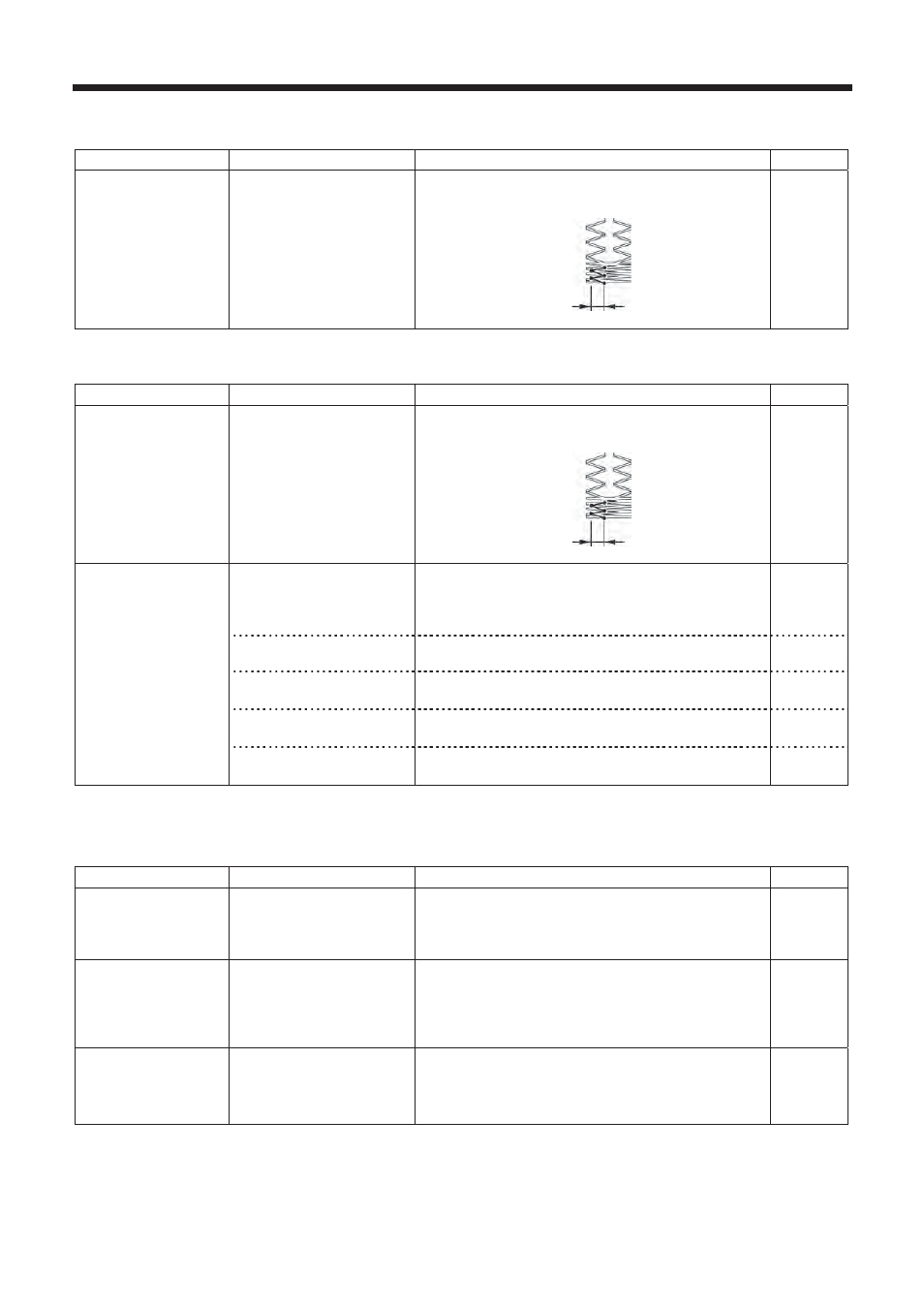

Backtack

shape

Check the backtack

shape

Set the value for parameter No. 68 to 1.0.

* If the value is set to 1.0, the rear tack will change.

45

ውዒ-ውዌ. Uneven seams (8) …… Thread sticking out at end backtack

Cause Check

Remedy

Page

Backtack

shape

Check the backtack

shape

Set the value for parameter No. 68 to 1.0.

* If the value is set to 1.0, the rear tack will change.

45

Work clamp pressure

Increase work clamp pressure.

* The standard height of the adjustment screw is

approximately 30 mm, so tighten it further than

this.

74

Work clamp

When using knit material, replace with the –3 work

clamp and needle plate.

-

Upper thread scissors

opening timing

Adjust to an appropriate opening timing.

76

Upper thread scissors

operation

Apply grease to the inclined face of the opening

cam.

76

Uneven material

feeding

Lower thread clamp

opening timing

Adjust so that the lower thread clamp plate opens

when the feed mechanism moves 6 – 7 mm.

77

ውዒ-ውው. Uneven seams (9) …… Sticking in needle plate

Front and rear tack sections of material gets stuck in needle hole

Cause Check

Remedy

Page

Start backtack

Number of start backtack

stitches

Use parameter number 40 to reduce the number of

stitches in the front tack.

* If the material is soft, it can be effective to set the

number of stitches to 0.

41

Rear tack

Rear tack vector shape

Use parameter number 37 to set the rear tack

vector shape to a rectangle.

* Setting the vector shape to a rectangle can be

effective when the width is less than the bar tack

width.

41

Needle plate

Needle plate

When using knit material, replace with the –3

needle plate.

Replace with a needle plate with a smaller needle

hole.

-

4004Q

4004Q

1.0

1.0