J.P. Instruments EDM 930 Primary Primary Installation Manual User Manual

Page 2

FAA Approved Installation Manual for the

Report No 908

EDM-900 and EDM-930

Page 2 of 50 Rev J

Primary Engine Data Management System Date 5-24-14

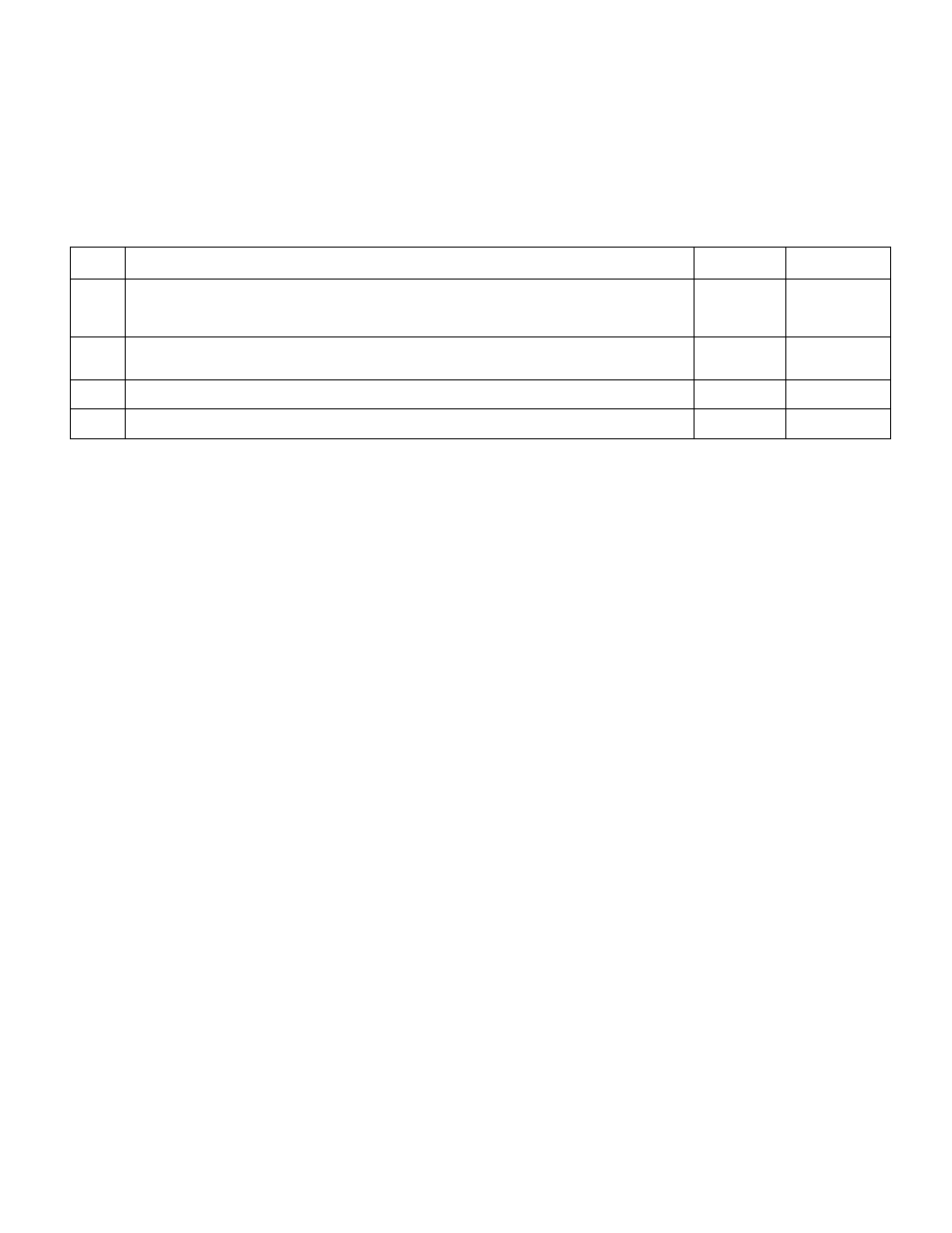

1. Revisions

REV Description

Date

Approval

G

Added new pictures of 900 and 930, page 6. Abbreviations page 4. Revised how the

JPI data base functions, page 3. Added revision box. Page 2. Added fuel level

calibration, page 22. Renumbered all pages.

9-28-2011 JFP

H

Revised to include new trouble shooting section for ICA and renumber pages. Updated

pressure sensors to i2s

12-02-2011 JFP

I

Revised TSO Label to show lighting change and added ARINC 429 wire chart

1-18-2013

JFP

J

Updated Part Numbers and Added new ICA and Pressure bulkhead paragraph

5-24-2014

JFP

2. Read This First

The following notes apply to a new installation. Read this section before proceeding.

The JPI warranty found in the back of the pilots guide clearly states that JPI will replace defective parts under

warranty, but does NOT cover labor to remove or install any parts.

The most common cause of probe problems is poor terminal crimps. Crimp ring terminals with AMP tool or

equivalent. Fold back the wire double before crimping terminals.

Do not use aluminum fittings or Teflon tape or pipe sealant with the FXT-201 or FXT-231 fuel flow transducer.

Write down the K-factor engraved on the side of the fuel flow transducer here _______. Once the transducer is

installed and covered with the fire sleeve, you will not be able to access this K factor.

Determine the locations of all holes before drilling to ensure that nothing interferes with the probe, clamp, clamp

screw or wire.

Provide service loops at the instrument so that it can be moved for maintenance or troubleshooting.

Thermocouple wire length is not critical. Trim to required length, allowing for service loops at the engine so that

probes can be swapped with probes on adjacent cylinders for troubleshooting purposes.

Dress all wires away from high temperature components such as exhaust stacks.

Never splice thermocouple wire using copper wire. Use only K-type thermocouple wire. Solder using zinc

chloride flux such as Nokorode brand – rosin flux alone will not work.

Observe correct polarity on all probe wires. Connect like colors together (red to red, yellow to yellow).

The instrument must be grounded at the engine, not at the avionics ground.

Record the installation of the EDM-900 or EDM-930 on a FAA form 337. Make an entry in the aircraft logbook.

Note: Removal of probes, sensors and the instrument is the reverse of the installation procedure.