Switch contacts, Switch contacts (optional) – WIKA 732.15.100 User Manual

Page 14

14

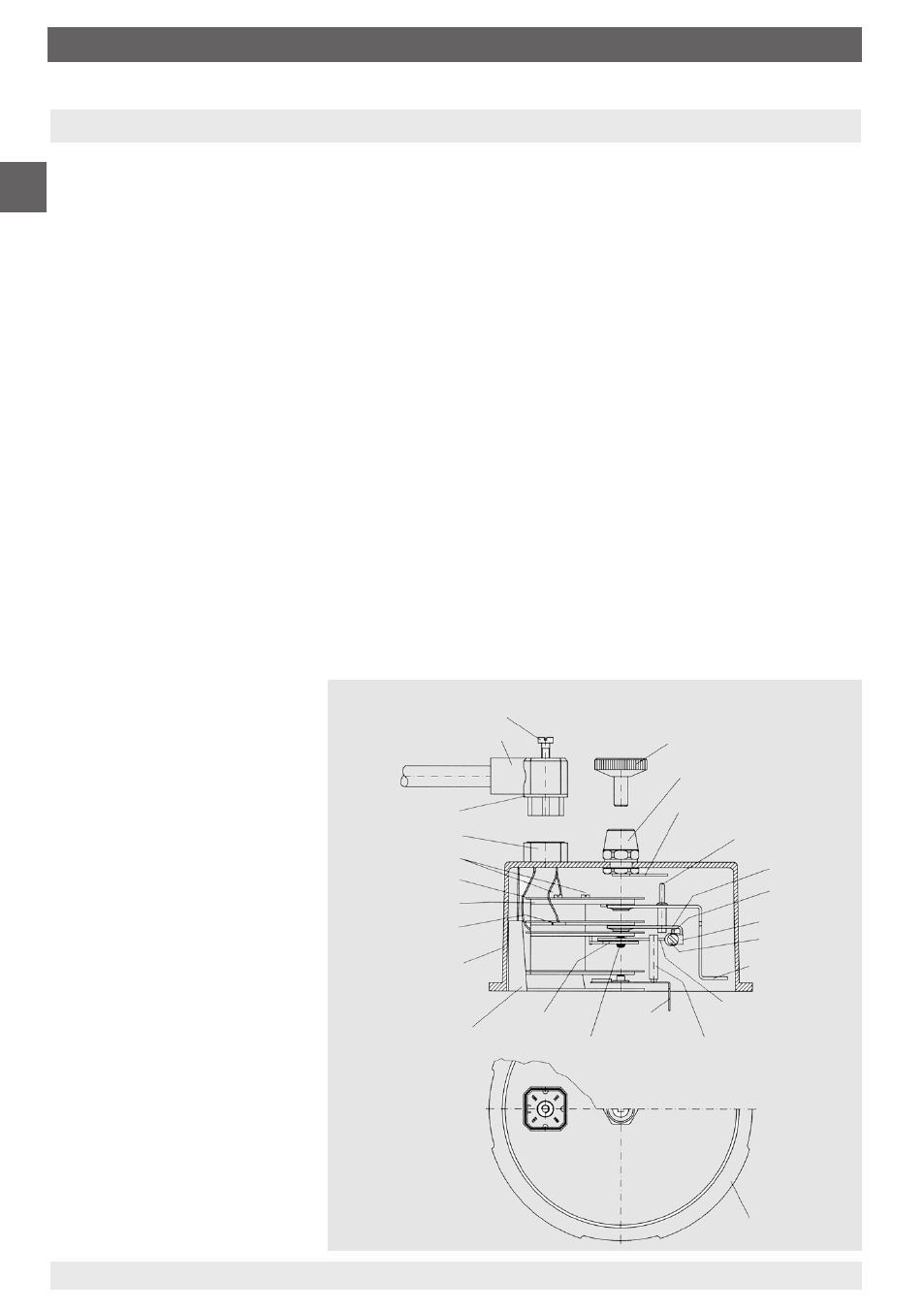

Spanner

Adjustable lock

Metal flag

Adjustable pin

Carrying arm

Contact pin

Magnet carrying

plate

Screw-in magnet

Desired value

indicator, red

Contact arm with

plate spring

Carrying pin of coupling fork

Coupling fork

Plug screw

Plug with cable

Plug seal

Plug socket

Type plate screws

Type plate

Front plate

Connection

Transparent hood

Special foot

with dovetail lead

Spiral spring

Ruby bearing

Bayonet rim

11592011.04 06/2014 GB/D/F/I

GB

WIKA operating instructions differential pressure gauge models 712.15.100, 732.15.100

10. Switch contacts

10. Switch contacts (optional)

These switch contacts are fitted into the case of a pressure gauge and intended to make or

break an electric control circuit triggered by the position of the instrument‘s pointer.

Versions

Single and double magnetic snap-action contacts or single and double inductive alarm

sensors. Please refer to data sheet AC 08.01 for technical data.

The modular switch contact is a self-contained unit, which can be built onto the pressure

gauge within a few minutes.

The switch contacts provide IP65 ingress protection even for oil-filled gauges. The connec-

tion to the instrument pointer is made by means of a special fork so that a carrying pin at

the pointer itself is not necessary. By means of this simple mounting, the instrument can be

converted into a contact measuring instrument quickly and inexpensively.

The switch contacts mainly comprise:

the pre-wired switch contact, which is provided with a special foot and a fork coupling

a transparent hood (polycarbonate) with dovetail lead into which the alarm contact is

pushed and which is fastened by means of a recessed head screw

a 4-pin plug socket, injection-moulded or welded to the transparent cover

an adjustable lock, mounted in the middle of the transparent cover.

The set pointers of the built-in

switch contact are adjusted, to

the value at which the contact

should switch, from the outside

via the adjustable lock using a

separate or a rigidly mounted

key.

The switch contacts are

designed to allow the instru-

ment pointer to move beyond

the adjusted set pointer after

contact actuation takes place,

with the contact remaining

actuated.

The design therefore guaran-

tees a stable switching condi-

tion, which corresponds to

the position of the instrument

pointer, even if the power fails.