10 eliminating faults – Festo Cтопорный цилиндр DFST User Manual

Page 25

DFST

Festo DFST 0710NH

25

10

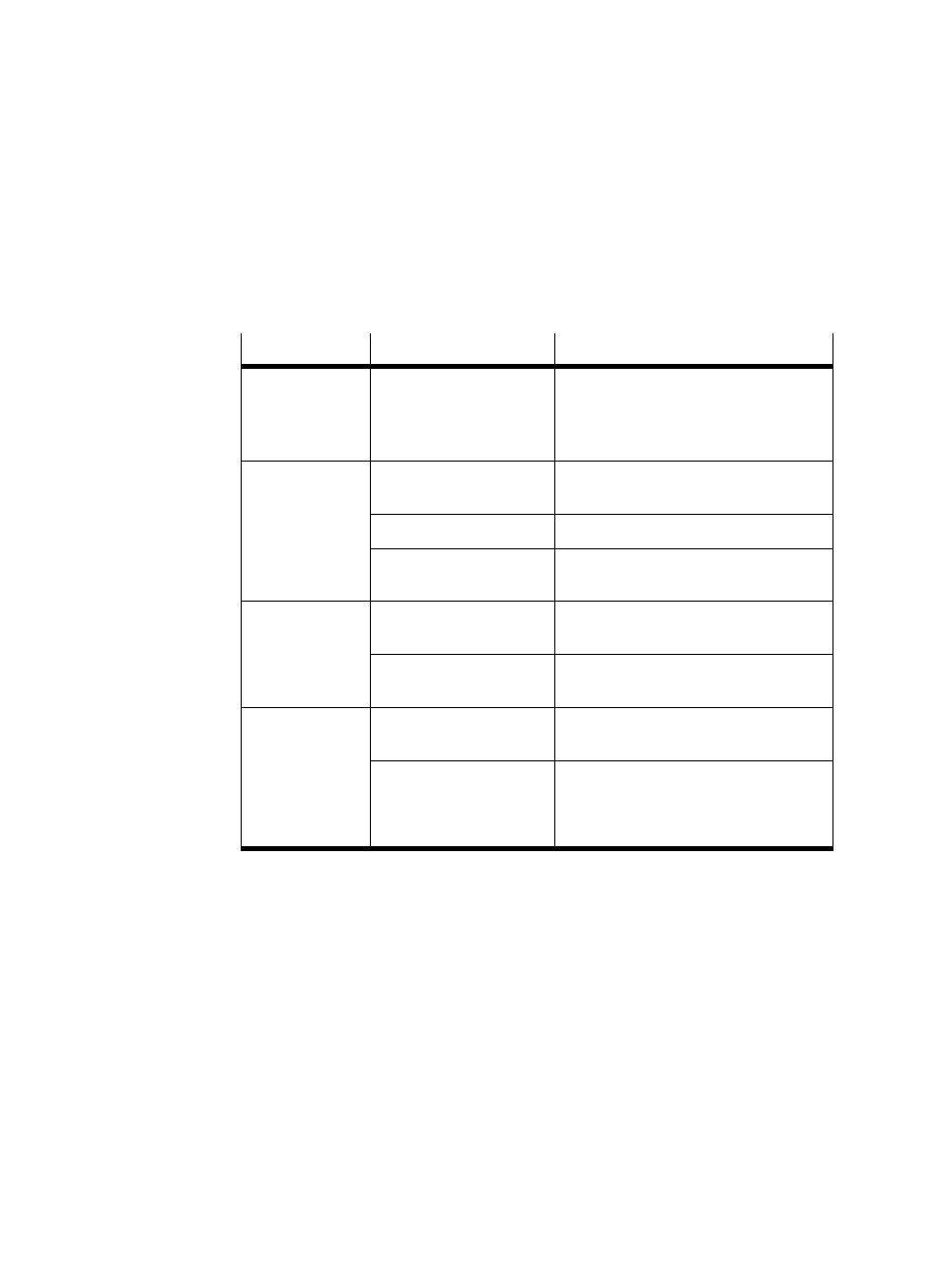

Eliminating faults

Fault

Possible cause

Remedy

Guide rod worn

on one side

Medium stream

approaches toggle lever

at an angle

Align stopper cylinder in transport

direction, medium stream must impact

toggle lever in a vertical position

(è Installation)

Hard impact on

the toggle lever

Cushioning incorrectly

set

Correct cushioning (è Commissioning)

Conveying speed too high

Reduce speed

Shock absorber defective

Replace shock absorber (è Spare

parts catalogue, www.festo.com)

Piston rod in

basic position

despite

Pipe connection error

Check blanking plug

Checking the pneumatic tubing

despite

pressurization

Reduced flow through

angled screw connectors

Avoid angled screw connectors

Toggle lever

does not reach

end position

Cushioning incorrectly

set

Correct cushioning (è Commissioning)

end position

Material stream mass

(pressure force) too low

Ĉ Increase mass

Ĉ Increase friction coefficient between

conveyor and material

Ĉ Increase gradient of conveyor

Fig. 27