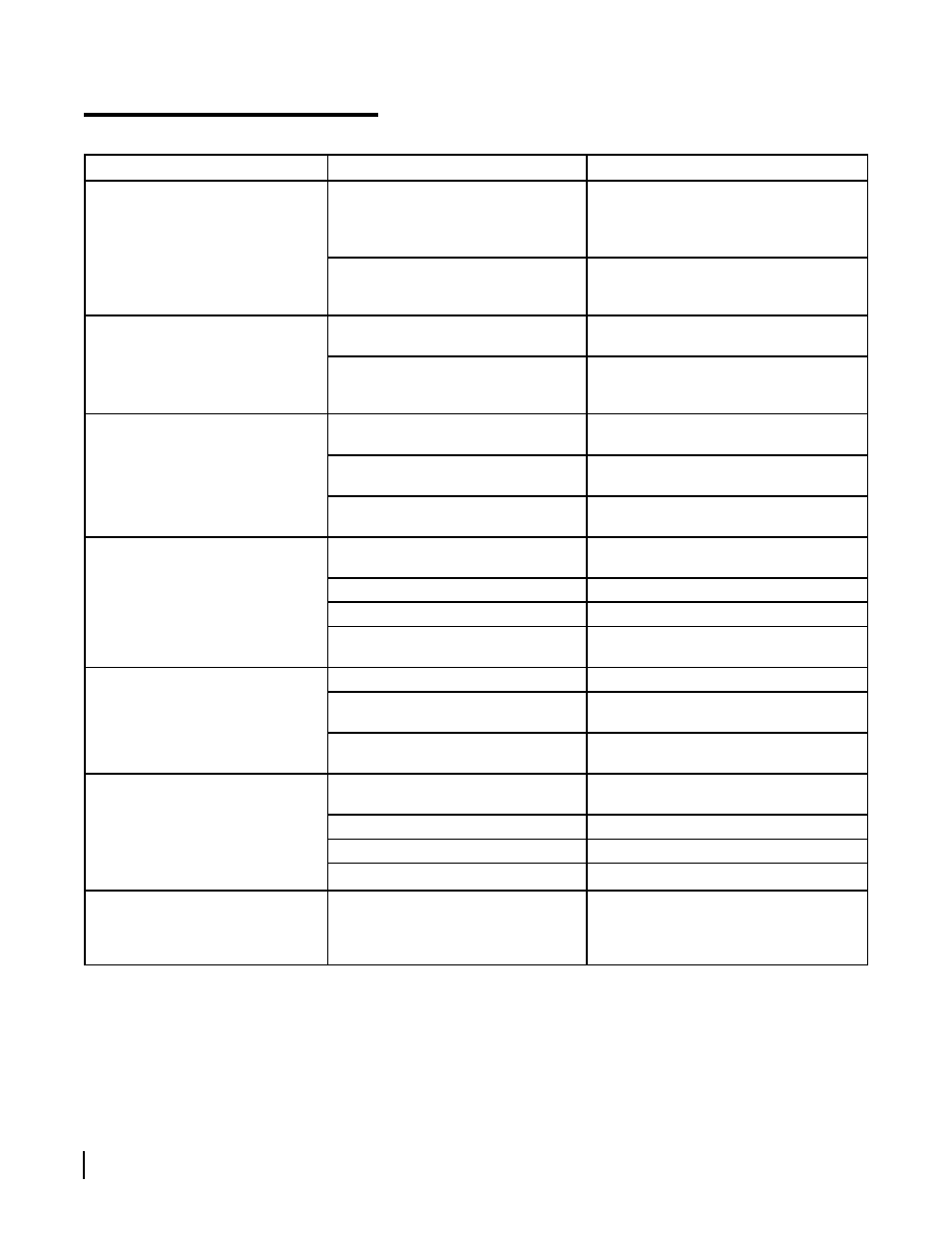

Troubleshooting, Problem possible cause(s) solution – SawStop CNS175-AU User Manual

Page 80

78 SawStop 10” Contractor Saw

Problem

Possible Cause(s)

Solution

The blade hits the brake pawl during

installation.

1. The brake position is adjusted too

close to the blade.

1. Turn the brake positioning bolt counter-

clockwise until the closest point

between the brake pawl and the blade

is about

1

⁄

16

inch to

1

⁄

8

inch.

2. The blade is the wrong size.

2. Use only a 10 inch blade with a

standard brake cartridge, or an 8 inch

dado set with a dado cartridge.

The gears sound/feel rough when

raising or lowering the blade.

1. There is dust or debris on the miter

gears or elevation shaft.

1. Clean components and regrease.

2. The elevation locking knob has not

been released.

2. Turn the elevation locking knob

counter-clockwise to release the

elevation handwheel.

The saw does not make accurate

45° or 90° cuts.

1. The tilt limit stops are not adjusted

properly.

1. Adjust the tilt limit stops.

2. The tilt angle indicator is not

adjusted properly.

2. Adjust the tilt angle indicator.

3. The miter gauge is not adjusted

properly.

3. Adjust the miter gauge.

The material binds when making a

rip cut.

1. The rip fence is not aligned with the

blade.

1. Align the fence to the blade.

2. The material is warped.

2. Select another piece of material.

3. The feed rate is too high.

3. Try again at a lower feed rate.

4. The spreader or riving knife is not

aligned with the blade.

4. Align the spreader or riving knife.

The cuts are not clean or even.

1. The blade is dull.

1. Replace or sharpen the blade.

2. The blade is coated with pitch, gum

or other material.

2. Clean or replace the blade.

3. The blade is not the correct blade

for the material or cut.

3. Replace the blade.

The saw vibrates too much.

1. The blade is damaged or

unbalanced.

1. Replace the blade.

2. The floor is uneven.

2. Move the saw to a level, even surface.

3. The bearings are worn.

3. Replace the bearings.

4. The motor belt is worn.

4. Replace the motor belt.

The motor starts slowly and/or fails

to reach nominal speed.

1. The voltage supplied to the motor is

incorrect.

1. Ensure the motor is wired to match

the power that is being supplied. If

using an extension cord, ensure the

extension cord is the correct gauge.

Troubleshooting