Preparing your saw for use – SawStop CNS175-AU User Manual

Page 30

28 SawStop 10” Contractor Saw

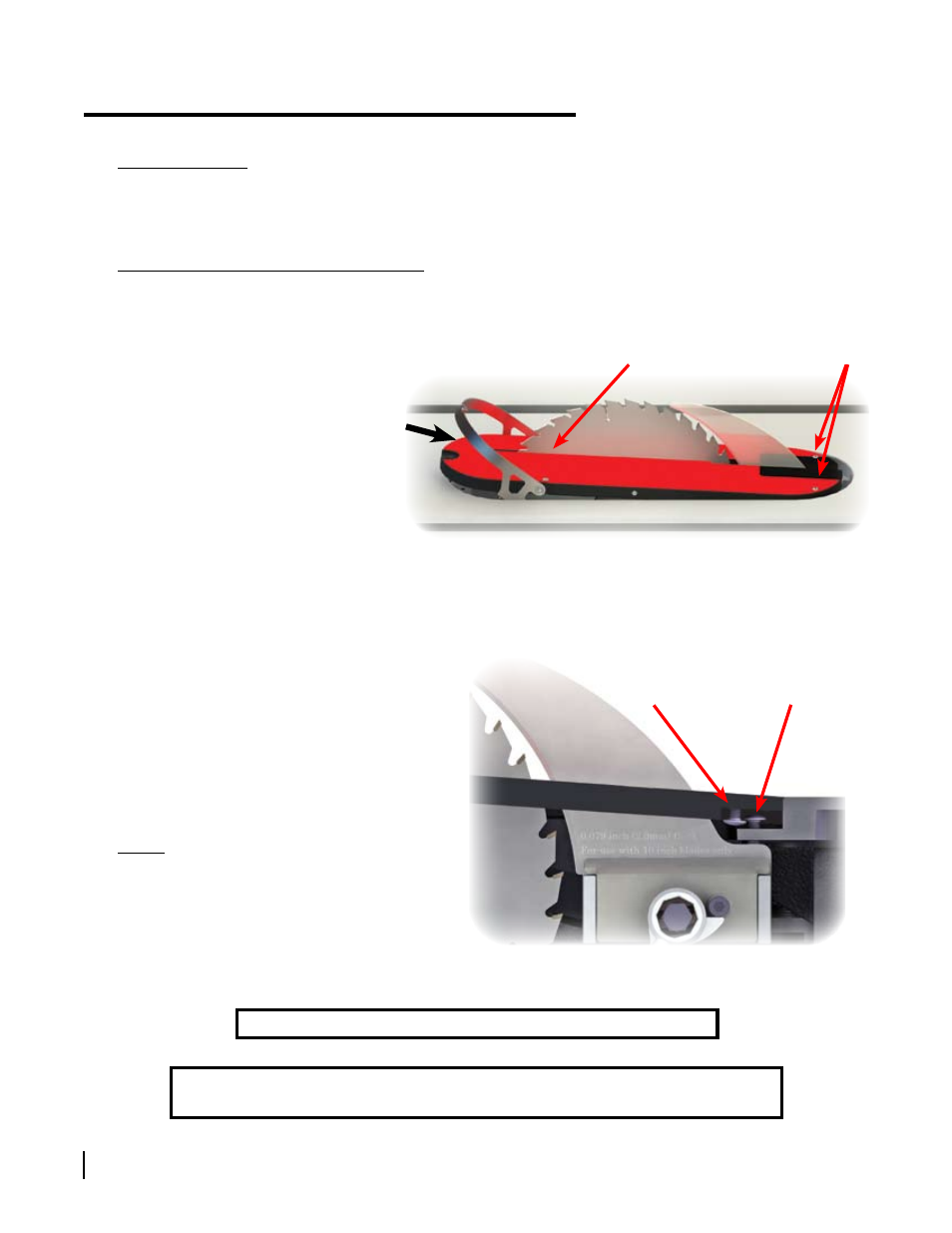

To install the table insert, hold it at a slight angle, with the lock-down lever rotated upwards and the rear of

the insert lower than the front (see Fig. 27). Slide the rear of the insert around the spreader or riving knife and

against the back of the table opening so that the heads of the rear lock down screws in the bottom of the insert

slide under the heads of the lock down screws

in the table opening (see Fig. 28). Then, with

the lock-down lever rotated upwards, lower the

front end of the insert into the table opening until

the insert lies flat. Finally, rotate the lock-down

lever all the way down so that it fits along the

edge of the table insert. Be certain that no part

of the table insert extends up beyond the table

surface; it should be flush or just below the table

surface.

Do not attempt to make a dado cut through the

standard table insert because the dado set will

hit the steel frame on the inside of the insert and

activate the brake cartridge. There is an optional

zero-clearance table insert accessory specifically

designed for dado cuts (see page 103).

Preparing Your Saw for Use

Saw Placement

Position the saw on a level surface away from sources of moisture and electrical noise. Make sure there is

sufficient room to allow free access to all sides of the saw.

Table Insert Removal and Installation

Your saw is shipped with a high-quality, zero-clearance table insert. The insert is factory-adjusted to fit securely

in the table opening and below the table surface. If you wish to perform additional adjustment on the insert,

see page 68 for instructions.

The rear of the table insert is held in

place by two lock down screws in the

bottom rear of the insert and two lock

down screws in the table opening. It

is held down in the front by latches

formed at the ends of a rotating lock-

down lever. The lock-down lever allows

you to easily remove the insert without

the use of tools.

WARNING! Never operate the saw without the table insert in place.

CAUTION! Do not use table inserts with metal or other electrically-conductive parts that

could contact the blade. This can cause the brake to be activated unnecessarily.

Fig. 27

Fig. 28

rear lock down screw

in table opening

hold insert at a slight angle to table

when installing or removing

rear lock down

screw in insert

rear lock down

screws